Rope guide device with adjustable rope guide device and casing pipe type rope pressing device

A casing type and rope-pressing technology is applied in the field of rope guides, which can solve the problems of breaking, breaking or pulling away, electric hoist can not be used, and the structure of the rope guide is fragile, etc. The effect of strong diagonal pulling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

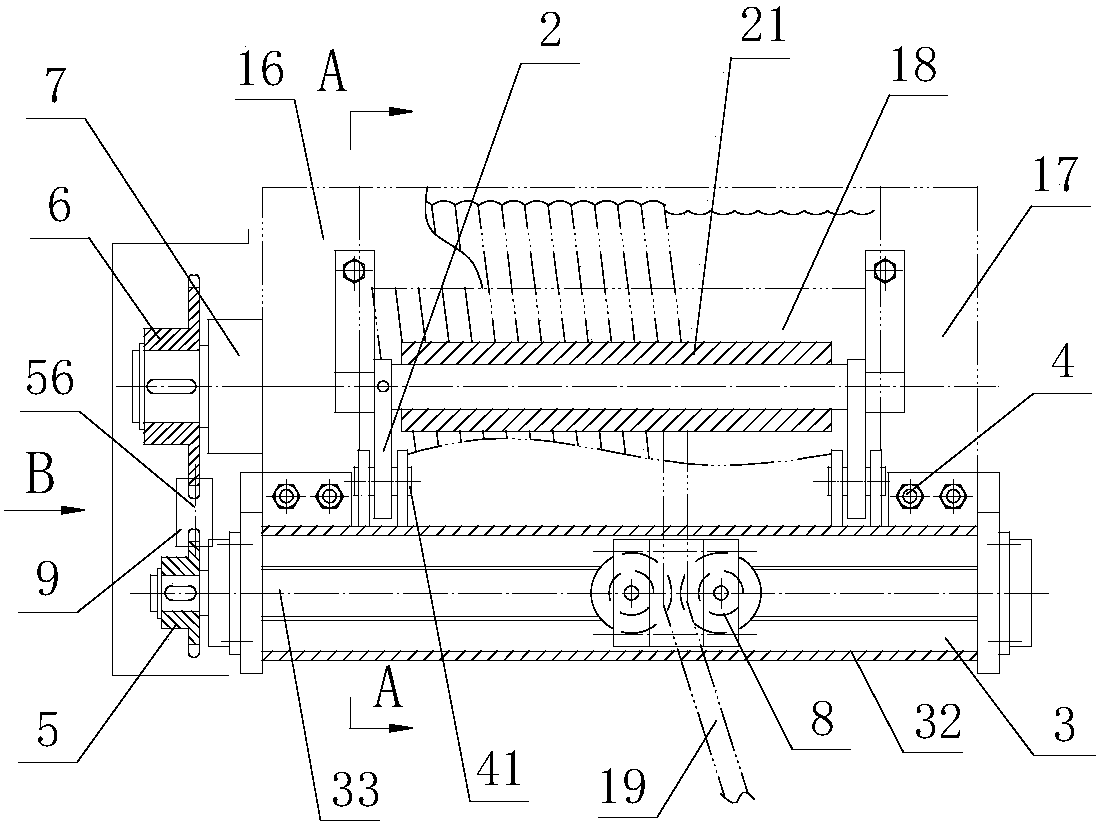

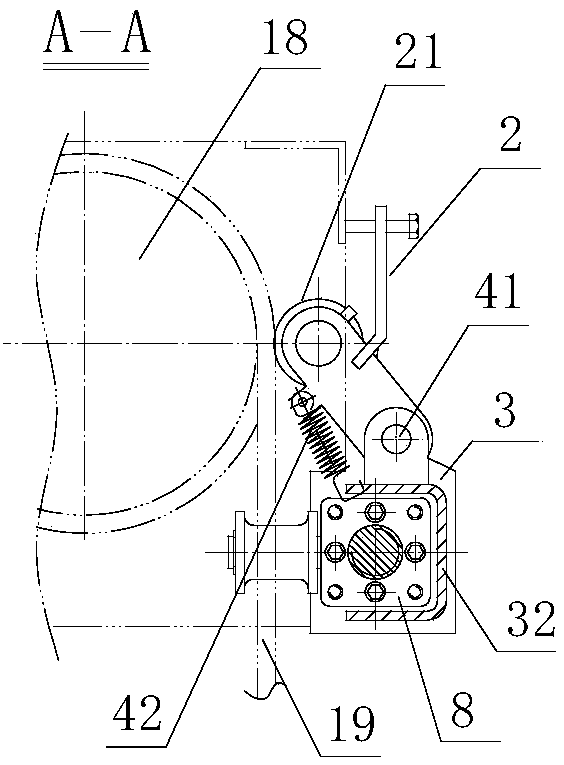

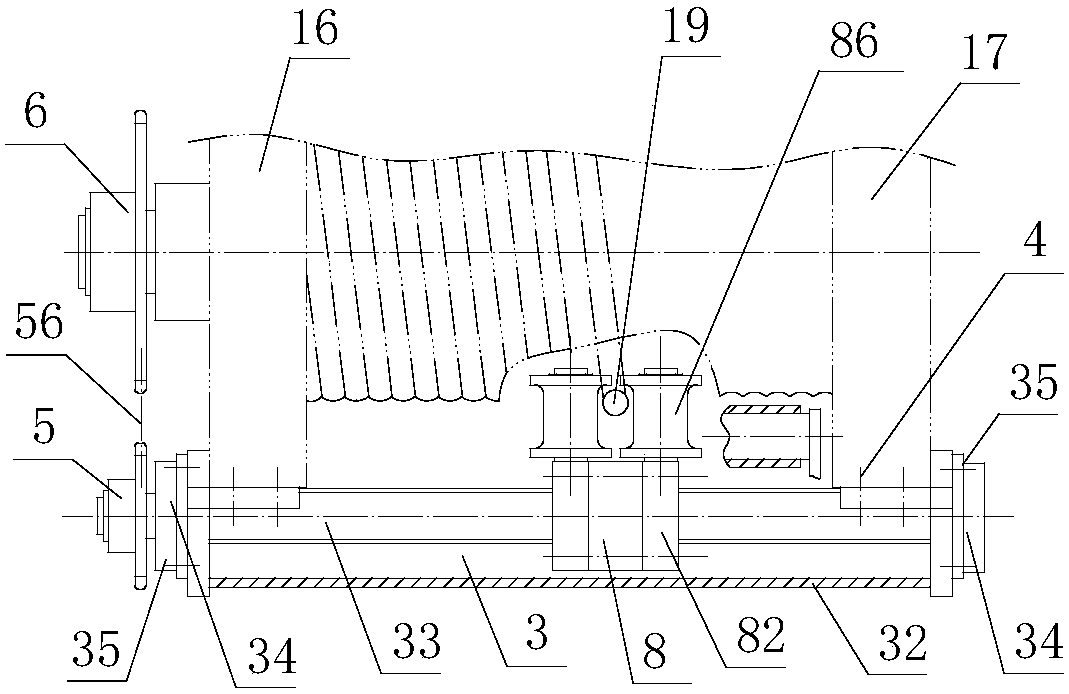

[0022] Such as figure 1 , figure 2 , image 3 As shown, a rope guide with an adjustable guide rope device and a sleeve-type rope presser includes a sleeve-type rope presser 2 and a thread guide mechanism 3; the sleeve-type rope presser 2 passes through a pin 41 is connected to the thread guide mechanism 3, and the sleeve-type rope pressing device is connected with the thread guide mechanism through a spring 42; the sleeve 21 on the sleeve-type rope pressing device is pressed on the reel 18 on the steel wire rope; the thread guide mechanism 3 is provided with an adjustable guide rope device 8; the two ends of the thread guide mechanism are respectively connected to the front of the drum outlet by bolts 4; the thread guide mechanism One end of the threaded shaft 33 on the top is connected to the small sprocket 5; the small sprocket is connected with the large sprocket 6 through a chain 56; the large sprocket is connected to the joint shaft 7; the joint shaft is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com