Worm-driven hand pulling block

A chain hoist and worm drive technology, applied in portable hoisting devices, hoisting devices, etc., can solve the problems of large body, inability to rotate 360°, and no chain guide device, etc., and achieve the effect of good strength and simple transmission mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

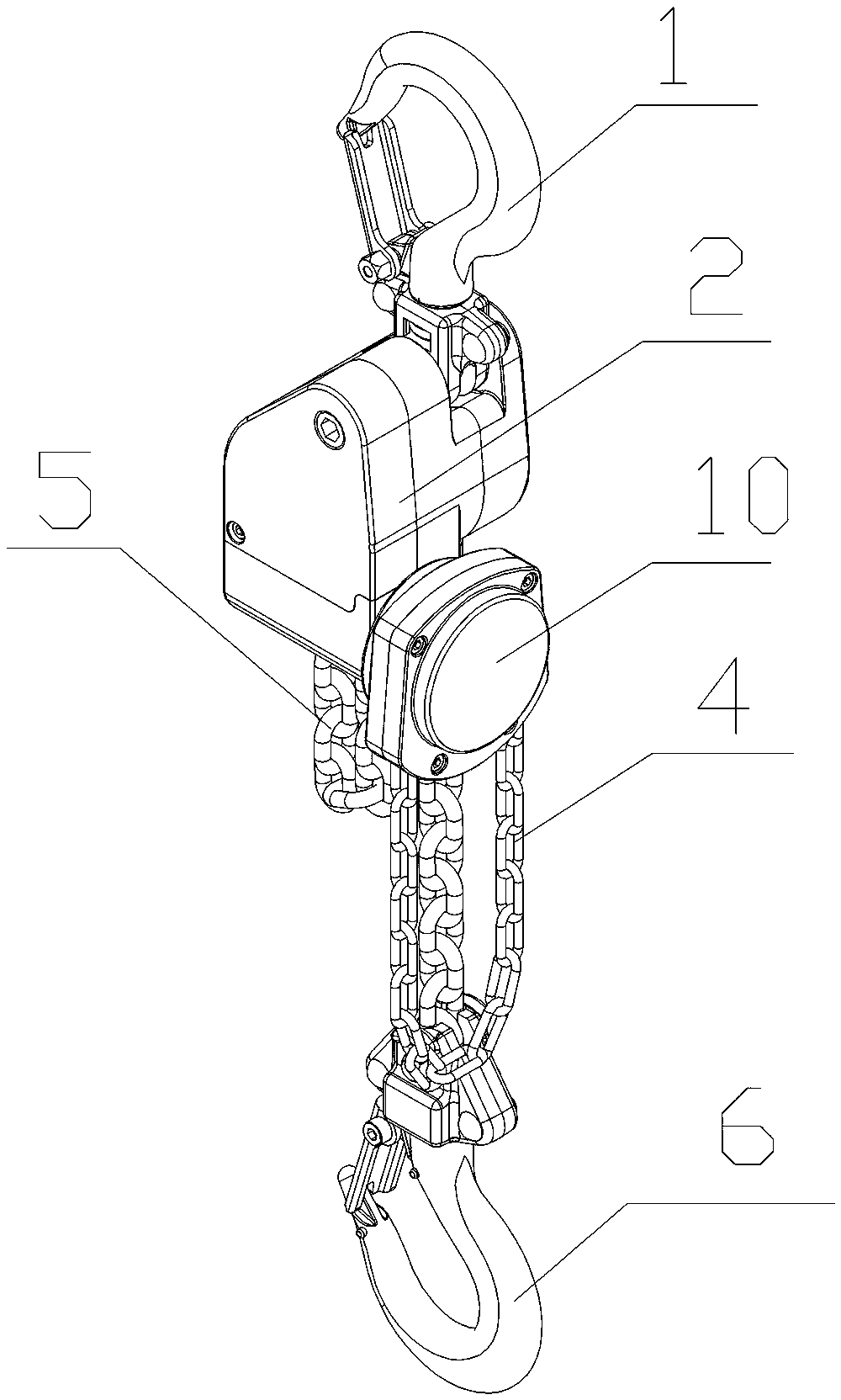

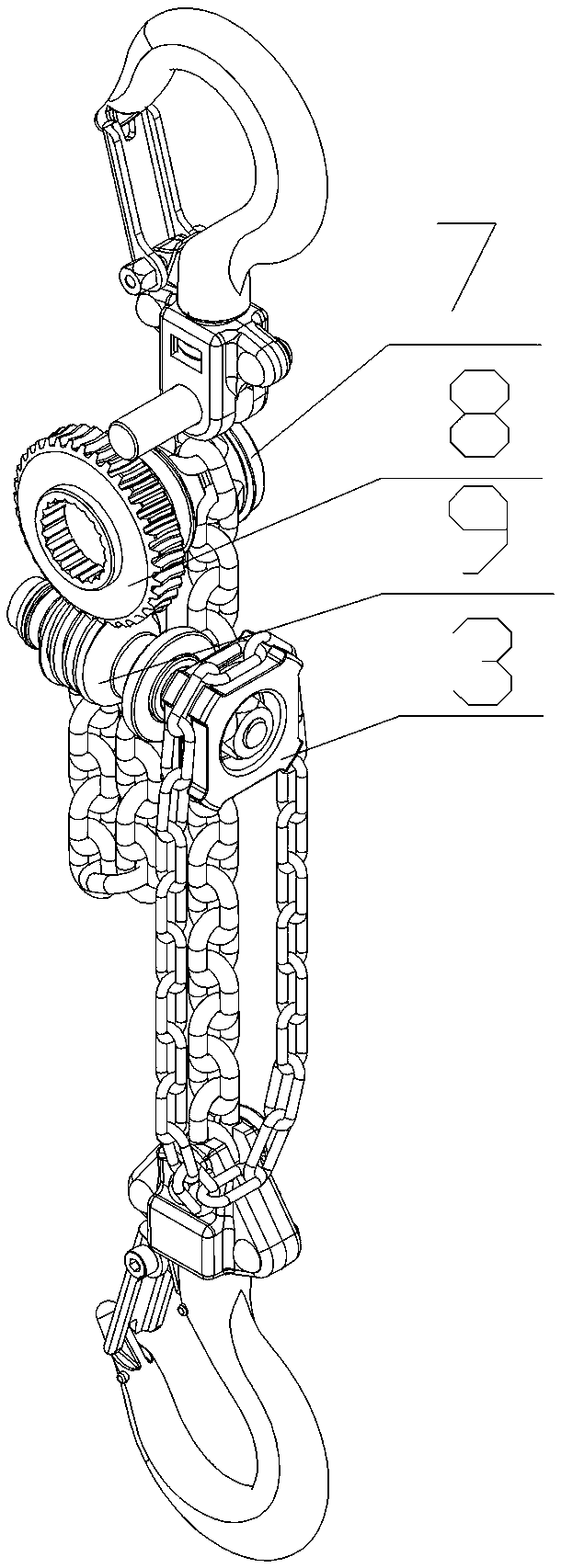

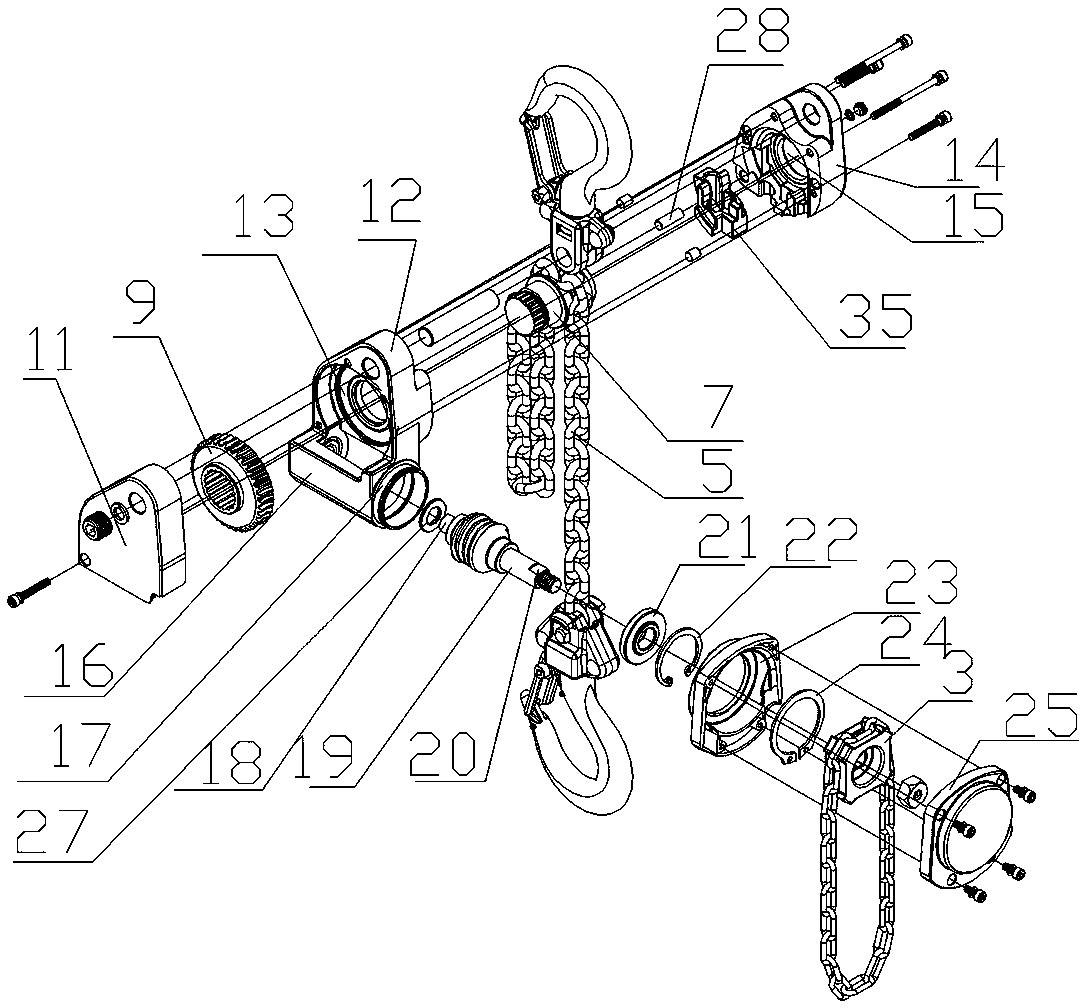

[0031] Such as Figure 1-11 As shown, a chain hoist driven by a worm is suitable for lifting heavy objects of small tonnage, including a frame 2, a lifting sprocket 7 arranged in the frame, and a lifting sprocket wound around the lifting sprocket. Chain 5, the upper hook 1 fixed on the upper end of the frame, the lower hook 6 fixed on one end of the lifting chain, the hand chain wheel 3 connected to the lifting sprocket through the transmission mechanism, and the hand chain 4 is wound around the hand chain wheel. The transmission mechanism includes The worm 9 that rotates synchronously with the hand chain wheel is engaged with the worm gear 8, and the worm gear transmission is connected with the lifting sprocket 7. The worm 9 is set as a toroidal worm, and the lead angle of the worm is set within the self-locking angle. The worm gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com