Bio-fertilizer fermentation device

A fermentation device and biological fertilizer technology, applied in the field of fermentation tanks, can solve the problems of difficult automatic production, complicated operation, time-consuming and labor-intensive, etc., and achieve the effects of avoiding long-distance transportation, good effect and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

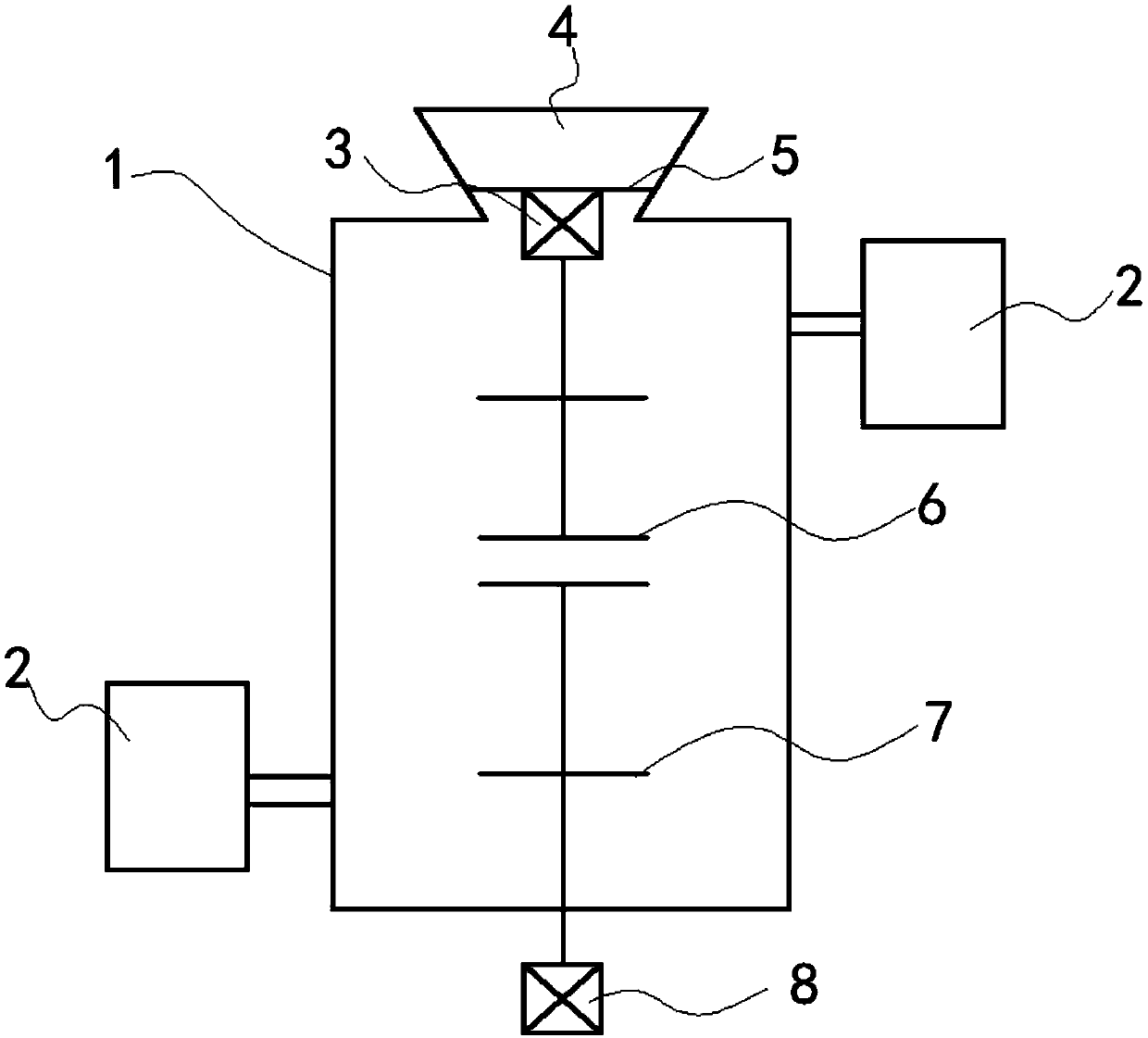

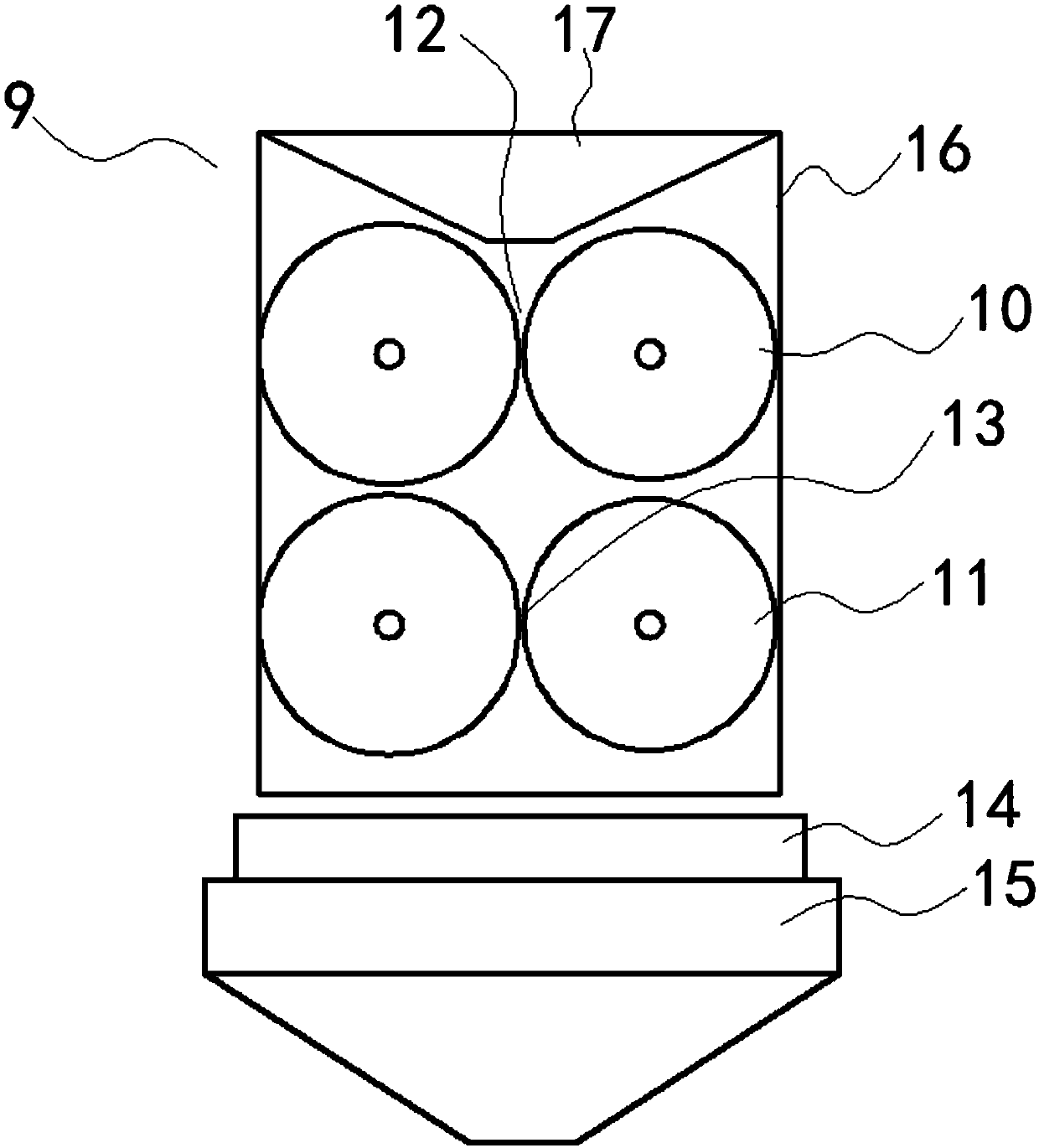

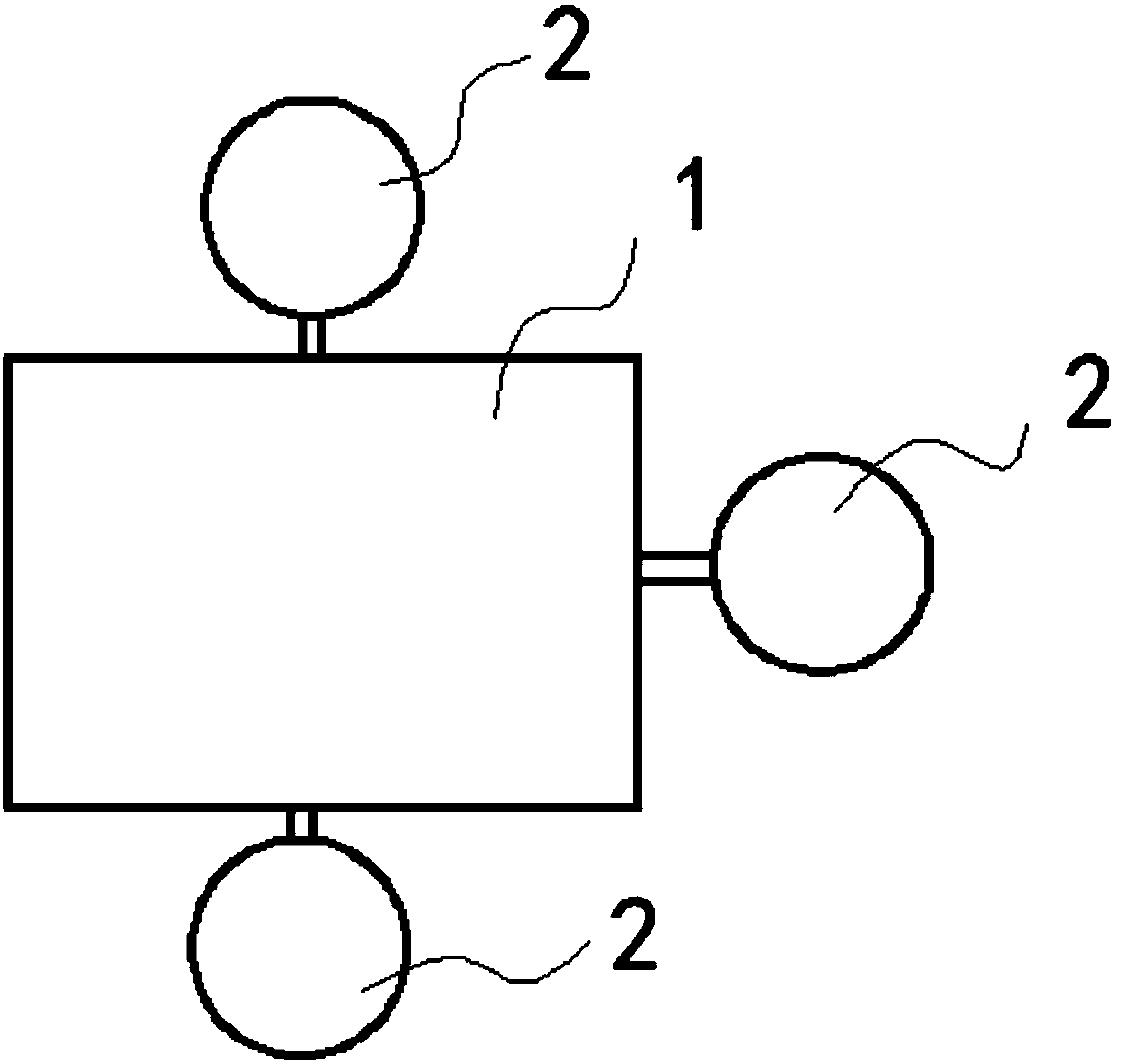

[0040] Such as figure 1 , 2 Shown in and 3, a kind of biological fertilizer fermentation device, wherein, comprises:

[0041] The main tank body 1 has a rectangular cross-section and has a cavity inside. The top of the main tank body 1 is provided with an upper opening, and the upper opening is matched with a funnel 4, and the lower part of the funnel is engaged with the opening. , the upper part extends upwards and outwards to form an open feed inlet, and a flat plate 5 is horizontally arranged on the upper opening of the main tank body 1, and the flat plate 5 is connected and fixed to the main tank body by at least three fixing bars, and the There is a gap for materials to pass between the flat plate 5 and the upper opening, and the bottom of the main tank body 1 is closed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com