A low-speed and high-torque hydraulic motor with two-end plate flow distribution

A low-speed, high-torque, hydraulic motor technology, applied in the field of fluid transmission and control, hydraulic pressure, can solve the problems of low volumetric efficiency, large leakage, short life, etc., to achieve the effect of improving volumetric efficiency, increasing service life, and reducing overall replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with accompanying drawing:

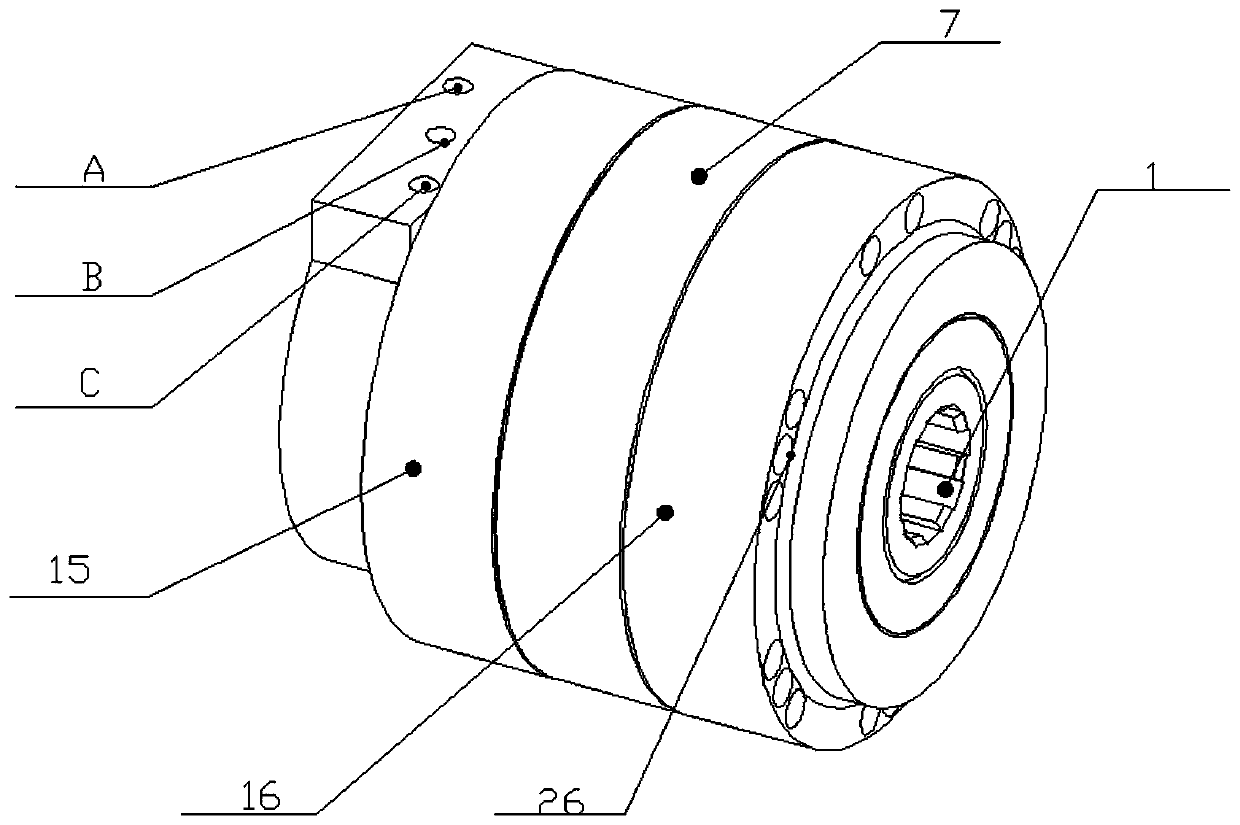

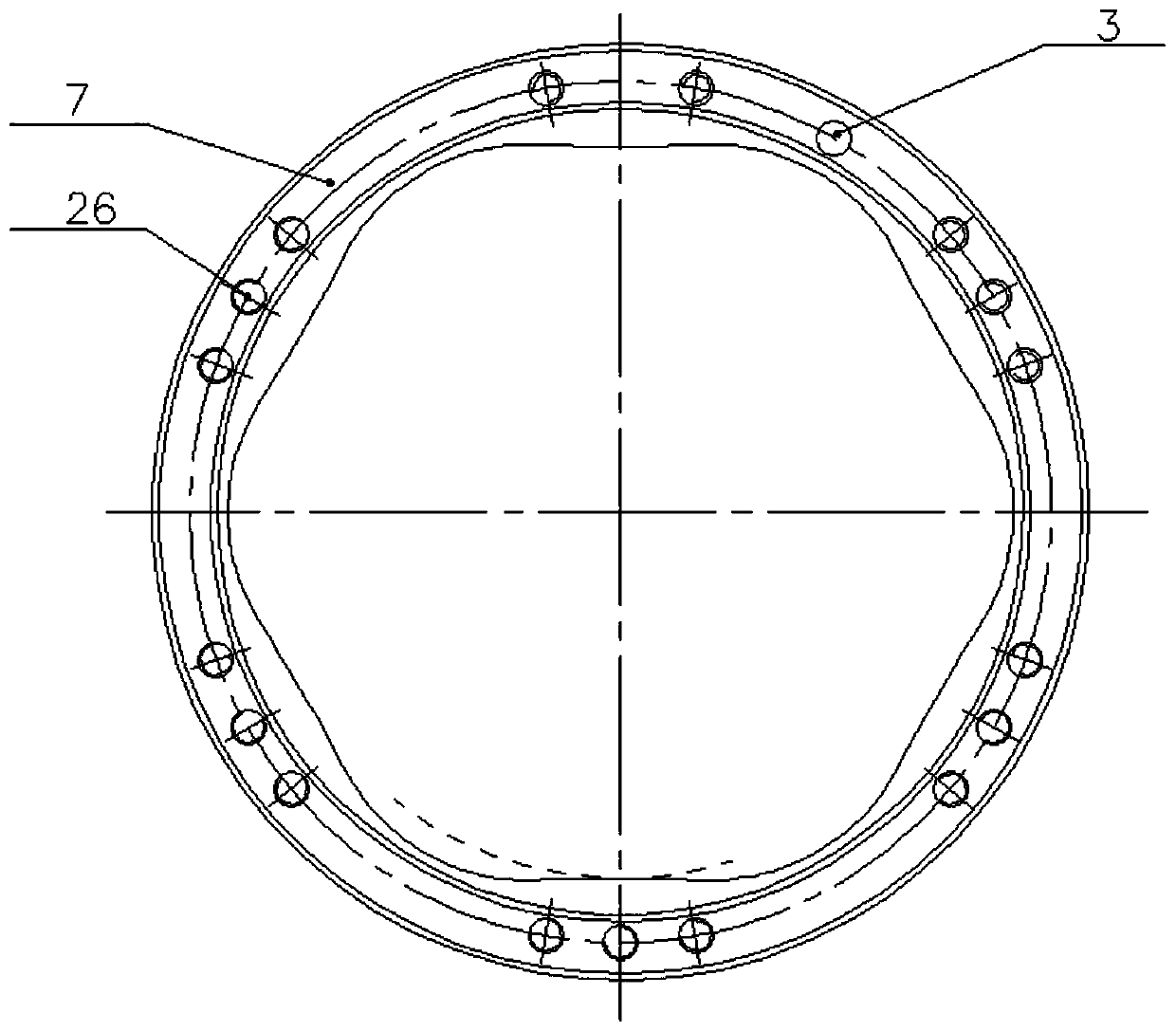

[0025] Such as figure 1 As shown, the rear end cover 15 and the stator 7, the front end cover 16 and the stator 7 are all connected through screw holes 26, and there are three holes on the rear end cover 15, which are inlet A, outlet B and leakage port C respectively; The end cover 15 and the front end cover 16 are connected by a flat key to prevent the right valve plate 2 and the left valve plate 12 from rotating together due to the friction force of the rotor 1; there is an internal spline protruding from the rotor 1 on the front end cover 16, which is convenient for contact with the external load connection, which greatly reduces the overall volume of the motor and improves the mechanical efficiency of the motor.

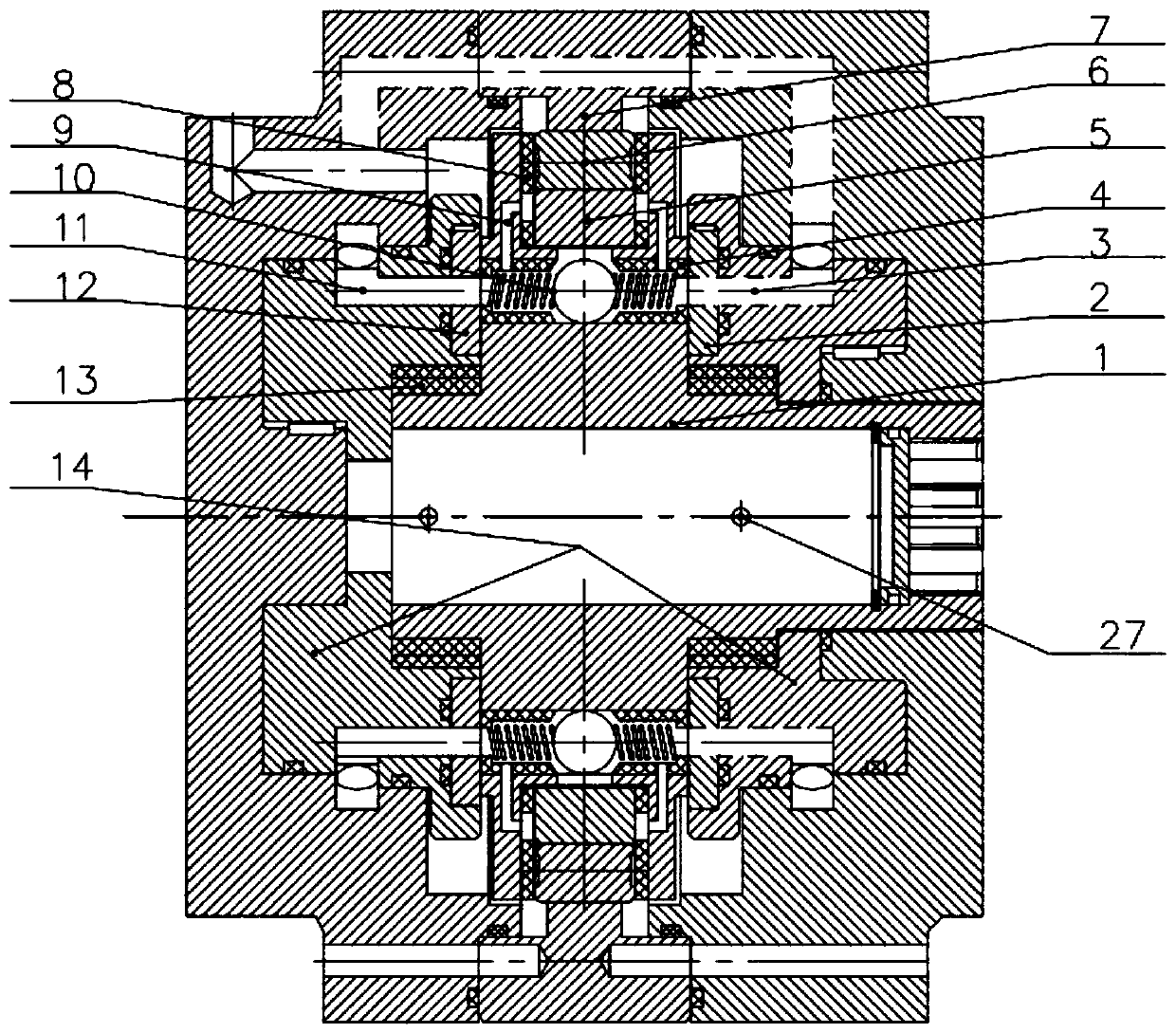

[0026] Such as figure 2 As shown, the rotor 1 is equipped with 10 plungers 5 and 10 ball valves 10 respectively, a sliding bearing 13 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com