Parallel-shaft transmission assembly with selectable electrification

A technology of transmission and assembly, applied in the field of motor vehicle parallel shaft transmission assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

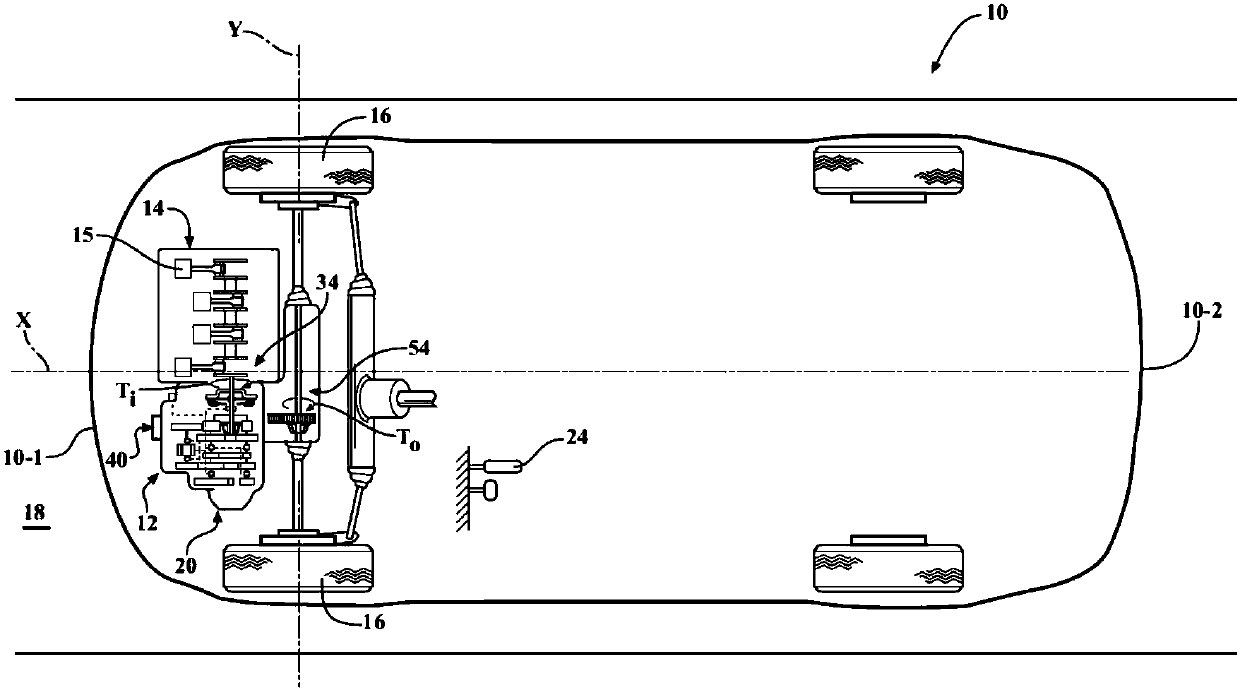

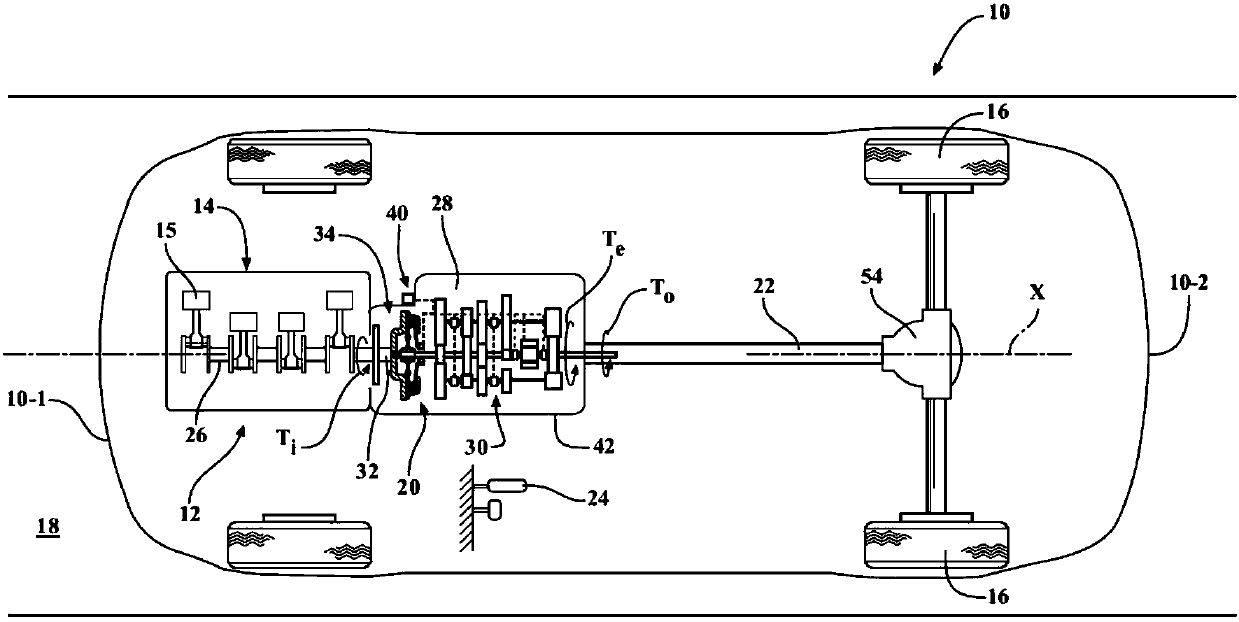

[0026] refer to figure 1 and figure 2 , depicts a vehicle 10 having a powertrain 12 . Vehicle 10 may include, but is not limited to, commercial vehicles, industrial vehicles, passenger cars, airplanes, boats, trains, and the like. It is also contemplated that vehicle 10 may be any mobile platform, such as an aircraft, all-terrain vehicle (ATV), boat, personal mobility device, robot, etc., for the purposes of the present invention.

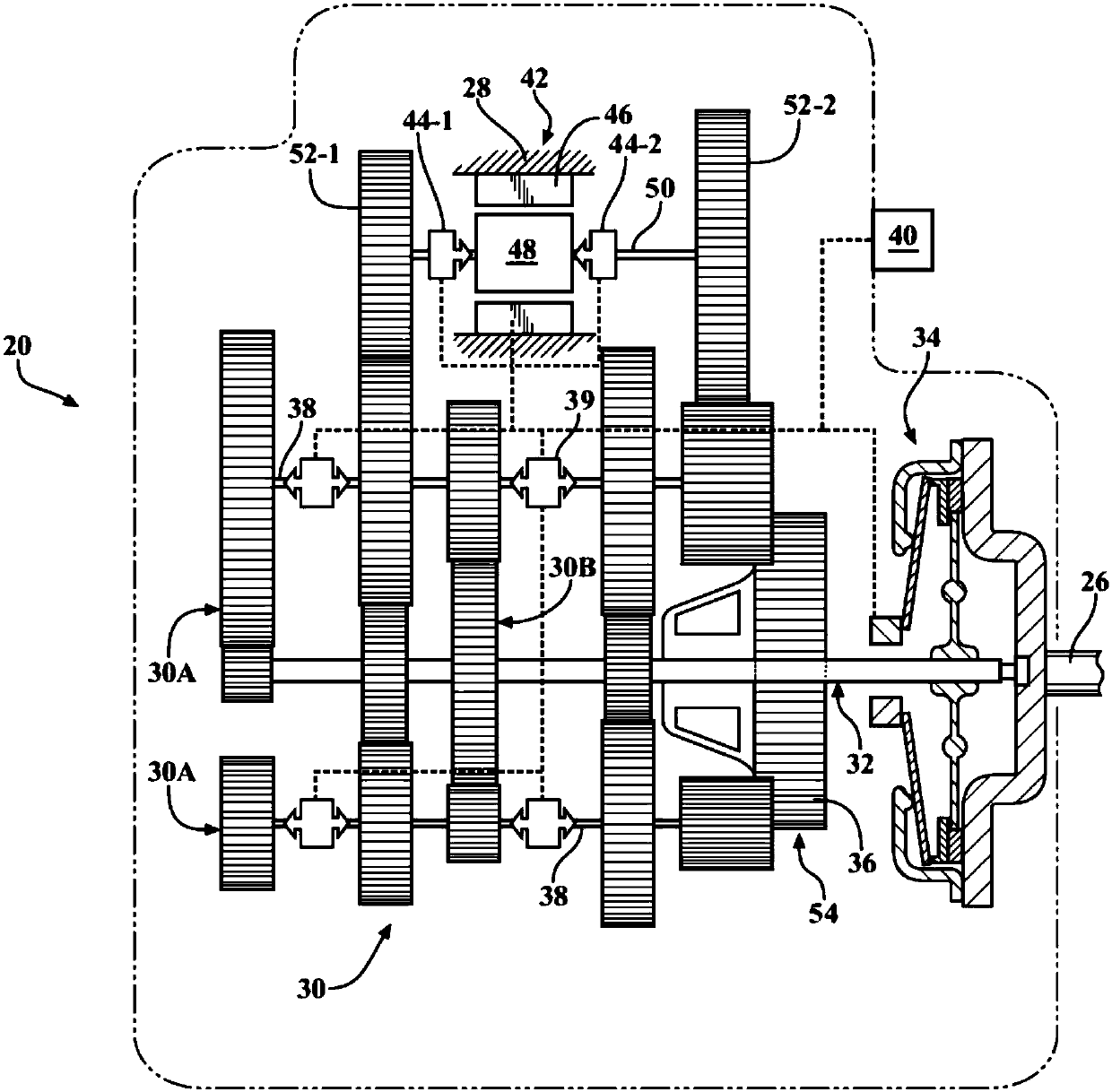

[0027] Powertrain 12 includes a power source 14 configured to generate torque T relative to a road surface 18 through driven wheels 16 i , for the propulsion of the vehicle 10 . The powertrain 12 also includes a transmission assembly 20 operatively connected to the power source 14, i.e. externally mounted to the power source and configured to transmit the torque T produced by the power source i Passed to the driven wheel 16. The transmission assembly 20 is further configured to receive and then increase or decrease torque T i , to obtain the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com