Polytetrafluoroethylene rubber pad

A technology of polytetrafluoroethylene and polytetrafluoroethylene layer, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., and can solve the problems of being susceptible to corrosion, reducing reliability, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

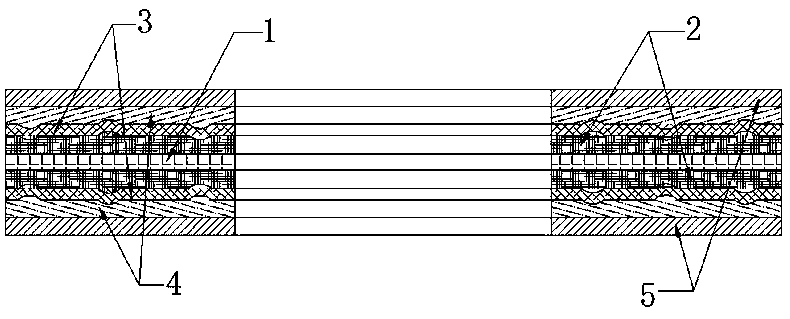

[0010] The polytetrafluoroethylene rubber pad of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0011] As shown in the figure, the polytetrafluoroethylene rubber pad of the present invention includes an annular rubber layer 1 and two layers of carbon fiber layers 2 bonded on the upper and lower surfaces of the rubber layer by an adhesive, the outer surface of each layer of carbon fiber layer 2 The metal layer 3 with pits and protrusions is composited, and the outer surfaces of the two metal layers 3 are bonded with two layers of asbestos layers 4 through an adhesive, and the outer surfaces of the two layers of asbestos layers 4 are bonded. The polytetrafluoroethylene layer 5 is bonded and compounded with an adhesive, wherein the thickness of the metal layer 3 is 1-3mm, and the structural design of the metal layer with this thickness makes it have high bonding strength and best reliability...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com