A valve device for increasing the opening and closing speed of the coating transition chamber

A technology of valve device and door opening and closing, which is applied in the direction of valve device, valve operation/release device, valve details, etc. It can solve the problems that the cylinder cannot reach the detection switch position, the cylinder pulls up and down slowly, and the waiting time of the glass is prolonged slowly. , to achieve the effects of shortening the intake time, improving the exhaust efficiency, and improving the sputtering film efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

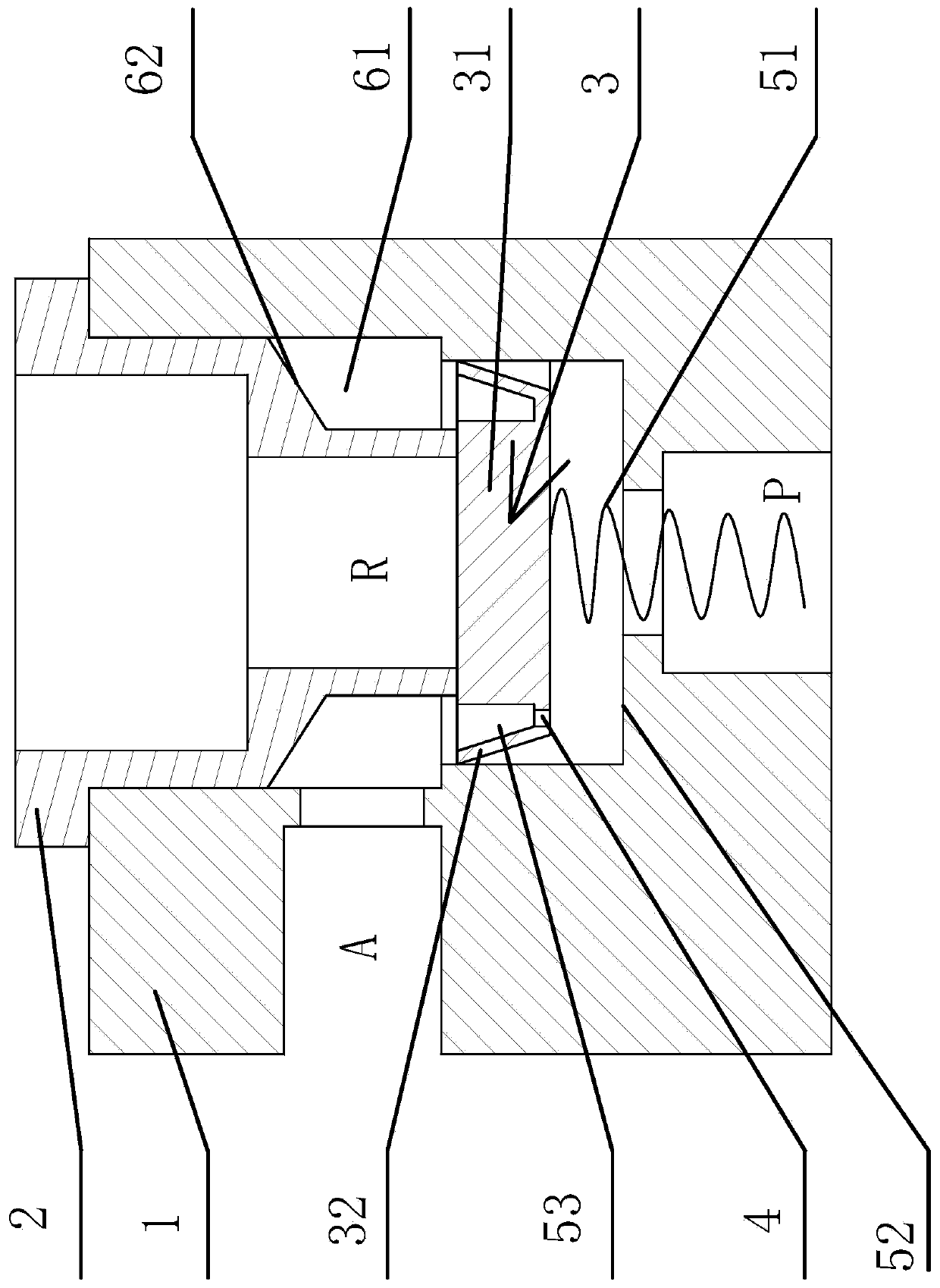

[0041] Such as figure 1 As shown, the valve device includes a main valve body 1, an auxiliary valve body 2 connected to the main valve body 1, and a cup piston 3 located between the main valve body 1 and the auxiliary valve body 2. The main valve body 1 has an air inlet port P and working port A, the auxiliary valve body 2 has an exhaust port R, and the cup piston 3 is provided with a main air intake hole 4 through the working port A and the air inlet P, and one side of the cup piston 3 is connected to the main There is a pre-tension spring 51 connected between the valve body 1, the other side of the cup piston 3 can cover the exhaust port R on the auxiliary valve body 2, the main valve body 1 has a stepped surface 52, and the cup piston 3 When moving down, the stepped surface 52 can cover the main air intake hole 4 on the cup piston 3 and connect the working port A with the exhaust port R.

[0042] Air intake: the air flow enters the working port A through the air inlet P an...

Embodiment 2

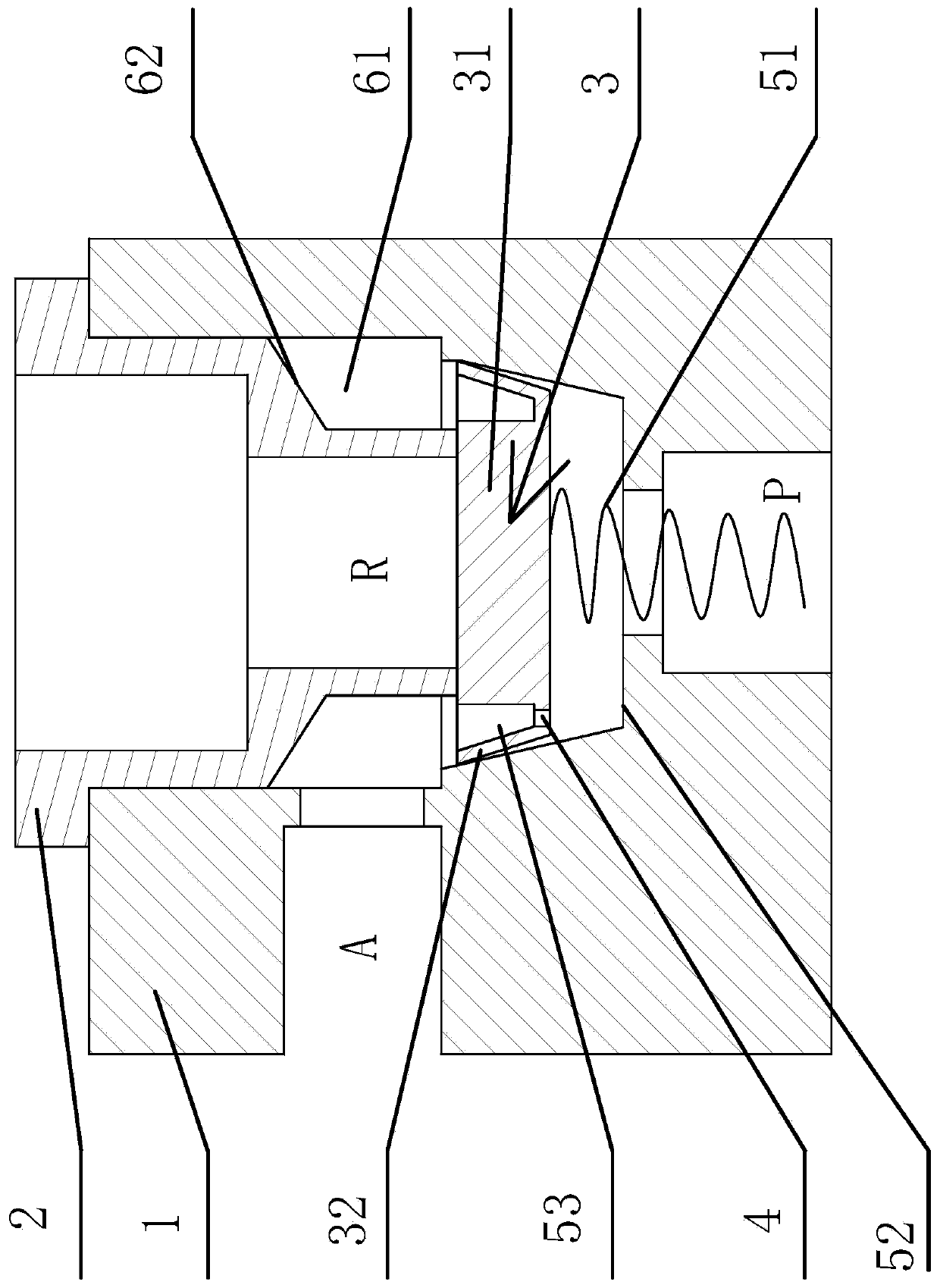

[0049] The content of this embodiment is basically the same as that of Embodiment 1, the difference is:

[0050] Such as image 3 As shown, the outer surface of the soft sealing ring 32 is a slope corresponding to the weakening groove 53, and the wall surface on the main valve body 1 that is sealed with the cup piston 3 is adapted to the outer surface of the soft sealing ring 32; 3 moves down, and when exhausting, the soft sealing ring 32 can be squeezed, thereby reducing the flow area of the main air intake hole 4, increasing the sealing strength between the cup piston 3 and the main valve body 1, and making the exhaust more efficient. Smooth, exhaust reaction time is shortened.

Embodiment 3

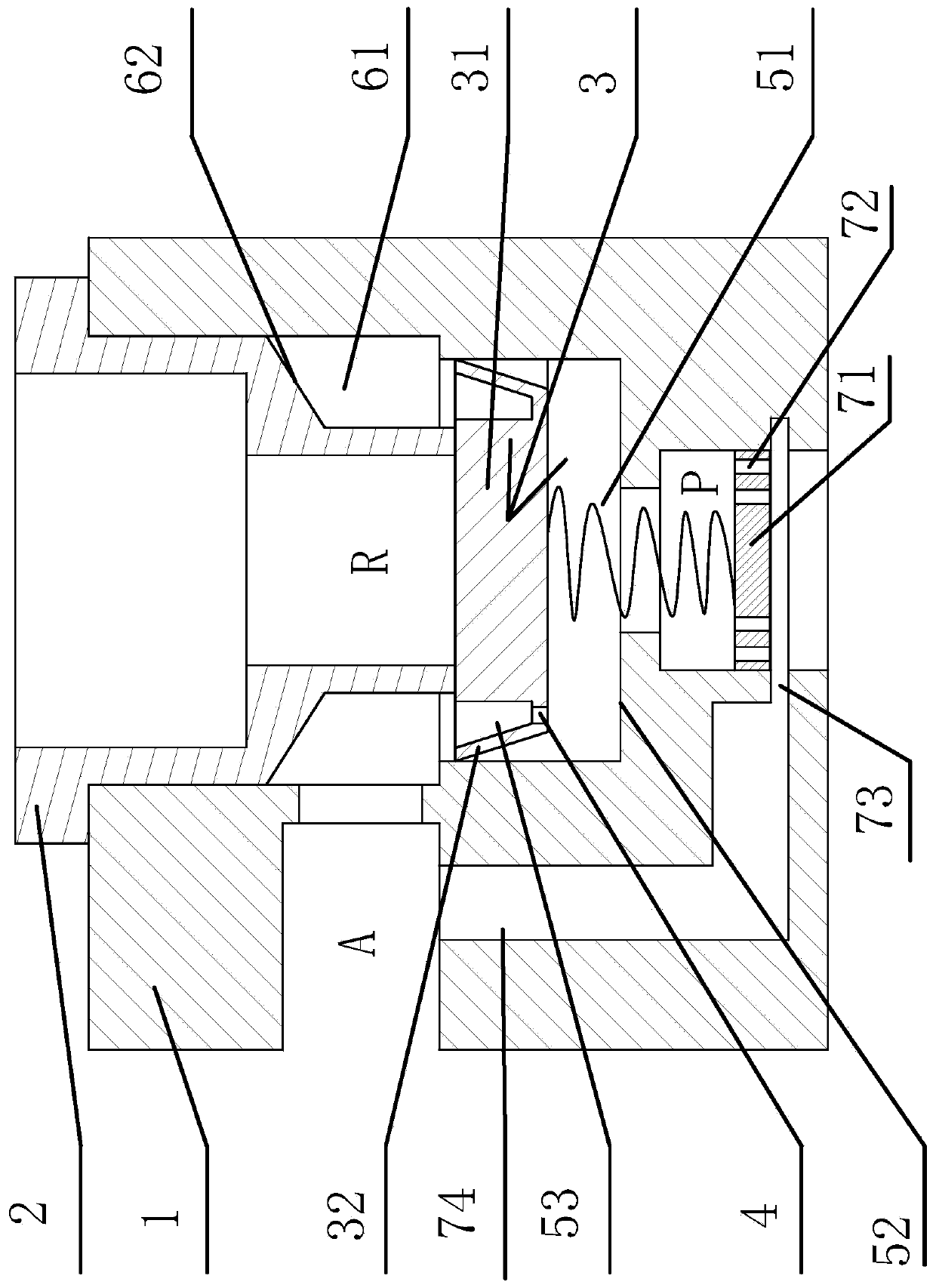

[0052] The content of this embodiment is basically the same as that of Embodiment 1, the difference is:

[0053] Such as figure 2 As shown, the air inlet P is provided with a valve block 71 that can move up and down along the peripheral wall of the air inlet P. The valve block 71 is provided with a through hole 72, and the two ends of the pre-tension spring 51 are respectively connected to the valve block 71 and the cup piston. 3. The main valve body 1 is provided with an annular air groove 73 that can communicate with the air inlet P, and an auxiliary air inlet 74 located in the main valve body 1 is provided between the air groove 73 and the working port A; the valve block 71 can Cover the air groove 73; when the intake air is being carried out, the valve block 71 can move up under the action of the intake air pressure, so that the intake port P and the working port A are connected, and the intake air can be quickly inhaled when the intake air pressure is high , shorten the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com