High-precision pressure stabilizing combination valve

A combination valve, high-precision technology, applied in the direction of multi-way valve, control valve, safety valve, etc., can solve the problems affecting the performance of the whole machine, the pressure reducing valve, the safety valve check valve is heavy, and the system weight index is occupied. To achieve the effect of compact structure, large pressure adjustment range and stable requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

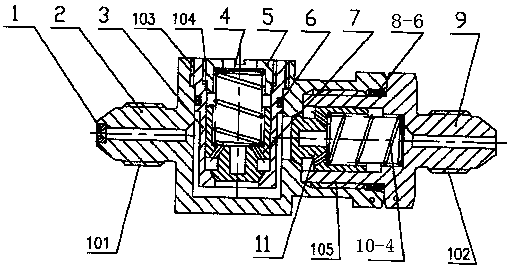

[0009] The pressure stabilizing combination valve involved in this technical solution is composed of a safety valve, a one-way valve, a shell and a joint, which are connected with each other through threads, the purpose is to save space, and the combined structure is required to have the function of pressure overload protection and Pneumatic system with reverse pressure cut-off function.

[0010] The embodiment is described in detail in conjunction with the above drawings, a safety valve 7 is placed in the safety valve core, a spring 4 is placed in the safety valve, a gasket is placed on the upper end of the spring 4, and the thread 104 on the adjustment screw 5 It is connected with the insert 3 to form a safety valve, and the adjustment screw is processed with a pressure relief hole, and the opening pressure of the safety valve is adjusted by adjusting the thickness of the gasket.

[0011] The safety valve is fixedly connected with the casing 2 through the thread 103 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com