A core material of a vacuum insulation panel, a vacuum insulation panel and a preparation method thereof

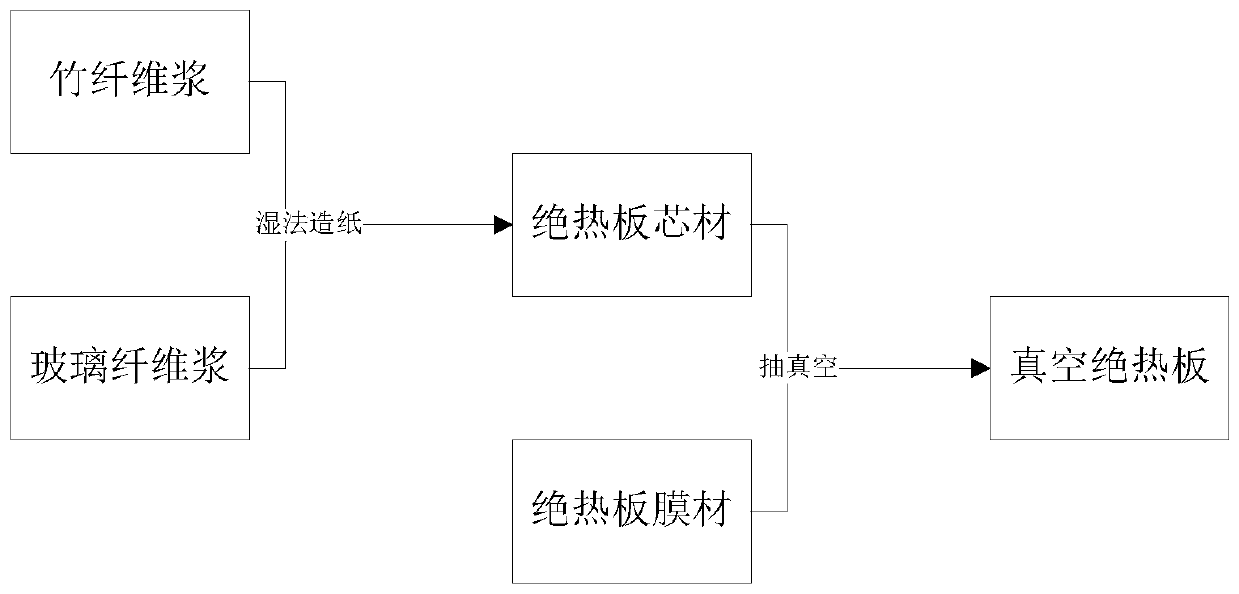

A vacuum insulation panel and core material technology, applied in the field of material science, can solve the problems of burden, high cost of inorganic materials, and high production cost of inorganic materials such as glass fiber, so as to reduce costs, reduce the amount of glass fiber used, alleviate environmental pollution and Effects of the serious problem of energy shortages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

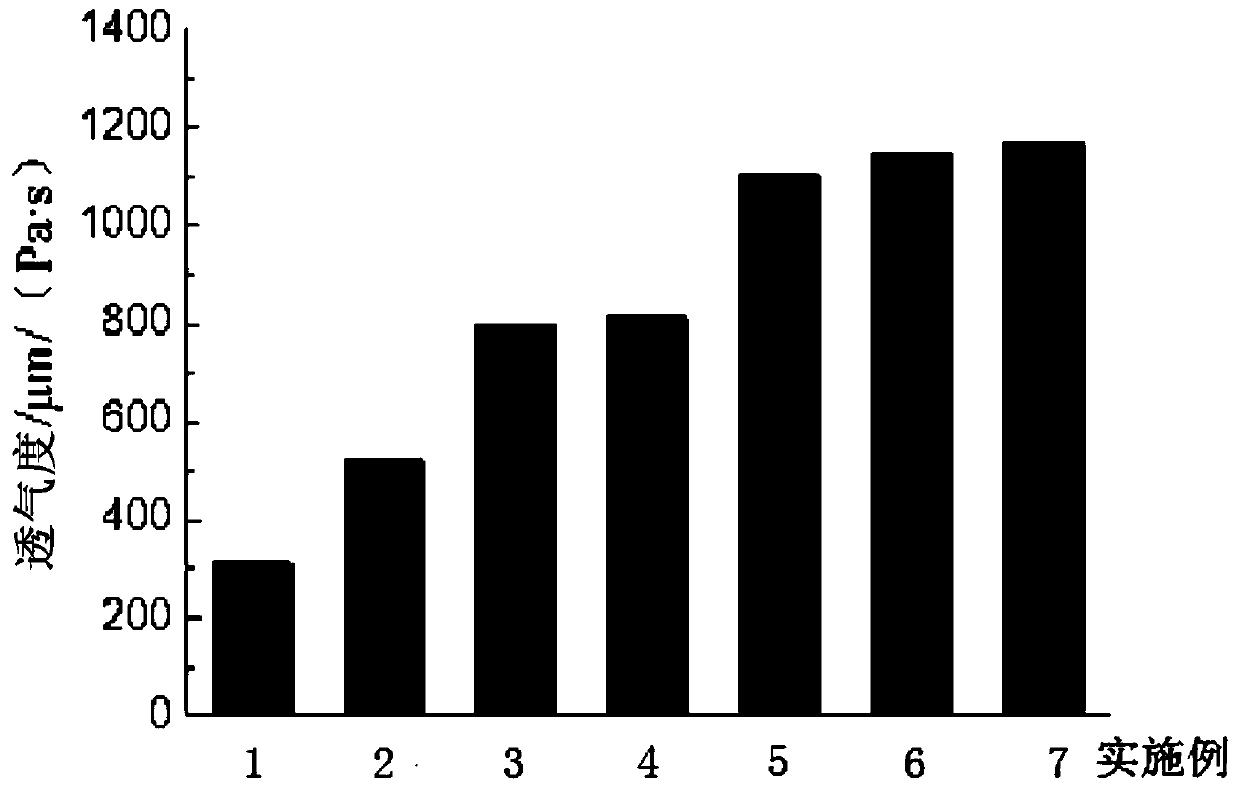

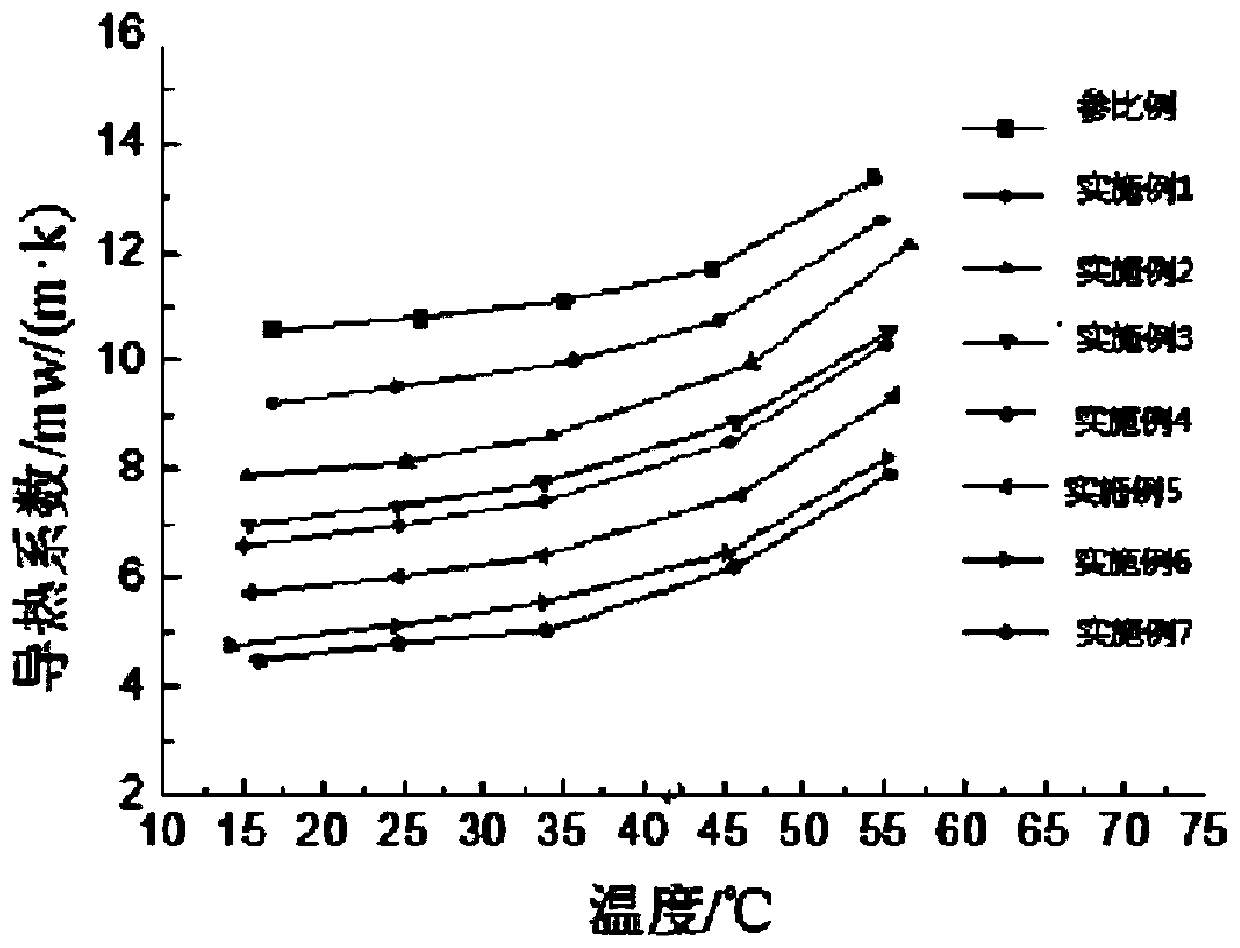

Embodiment 1

[0030] 1) Preparation of bamboo fiber pulp: at room temperature, weigh 360g of dry bamboo bleached pulp, put it in a 10L container, then add 5L of tap water, soak for 4h, and finally add it to the Valli beater, then add 18L of water Finally, start beating, and obtain the bamboo bleaching pulp that beating degree is 14.9 ° SR.

[0031] 2) Preparation of glass fiber slurry: Weigh 6.28g of glass fiber, put it in the container of the fiber dissociator, add 2300ml of water, then add 1.2g of sodium hexametaphosphate, use dilute sulfuric acid to adjust the pH of the solution to 3, and then set the defrosting switch The speed is 5000r / min, the time is 10min, and finally the dispersed glass fiber slurry is obtained.

[0032] 3) core material molding: respectively weigh two kinds of slurry according to the mass ratio of glass fiber pulp / bamboo fiber pulp 1:9, and evenly mix bamboo fiber pulp and glass fiber pulp, adopt wet papermaking technology to carry out papermaking, obtain core Ma...

Embodiment 2

[0036] 1) Preparation of bamboo fiber pulp: at room temperature, weigh 360g of dry bamboo bleached pulp, put it in a 10L container, then add 5L of tap water, soak for 4h, and finally add it to the Valli beater, then add 18L of water Finally, start beating, and obtain the bamboo bleaching pulp that beating degree is 14.9 ° SR.

[0037] 2) Preparation of glass fiber slurry: Weigh 6.28g of glass fiber, put it in the container of the fiber dissociator, add 2300ml of water, then add 1.2g of sodium hexametaphosphate, use dilute sulfuric acid to adjust the pH of the solution to 3, and then set the defrosting switch The speed is 5000r / min, the time is 10min, and finally the dispersed glass fiber slurry is obtained.

[0038] 3) core material molding: respectively weigh two kinds of pulp according to the mass ratio of glass fiber pulp / bamboo fiber pulp of 1:4, and evenly mix bamboo fiber pulp and glass fiber pulp, and use wet papermaking technology to carry out papermaking to obtain cor...

Embodiment 3

[0042] 1) Preparation of bamboo fiber pulp: at room temperature, weigh 360g of dry bamboo bleached pulp, put it in a 10L container, then add 5L of tap water, soak for 4h, and finally add it to the Valli beater, then add 18L of water Finally, start beating, and obtain the bamboo bleaching pulp that beating degree is 14.9 ° SR.

[0043] 2) Preparation of glass fiber slurry: Weigh 6.28g of glass fiber, put it in the container of the fiber dissociator, add 2300ml of water, then add 1.2g of sodium hexametaphosphate, use dilute sulfuric acid to adjust the pH of the solution to 3, and then set the defrosting switch The speed is 5000r / min, the time is 10min, and finally the dispersed glass fiber slurry is obtained.

[0044] 3) core material molding: take two kinds of slurry according to the mass ratio of glass fiber pulp / bamboo fiber pulp 3:7 respectively, and evenly mix bamboo fiber pulp and glass fiber pulp, adopt wet papermaking technology to carry out papermaking, obtain core Mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com