Complicated narrow space deep foundation underground engineering combined inclination measuring method

A technology for underground engineering and deep foundations. It is applied in the direction of measuring inclination, measuring devices, surveying and navigation, etc. It can solve the problems of high cost of buried installation, errors, and delays in the construction period, and achieve convenient and economical construction, universal applicability, and simple calculation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

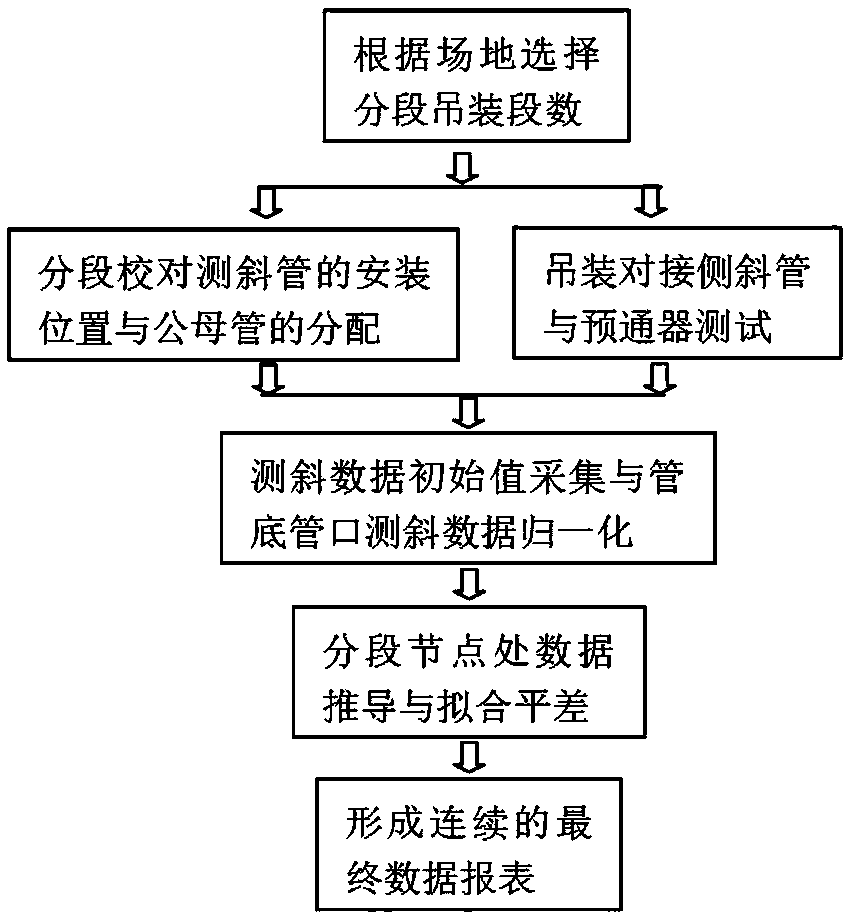

[0013] A combined inclinometer method for deep foundation underground engineering in complex and narrow spaces, comprising steps:

[0014] (1) Select the number of hoisting segments according to the site.

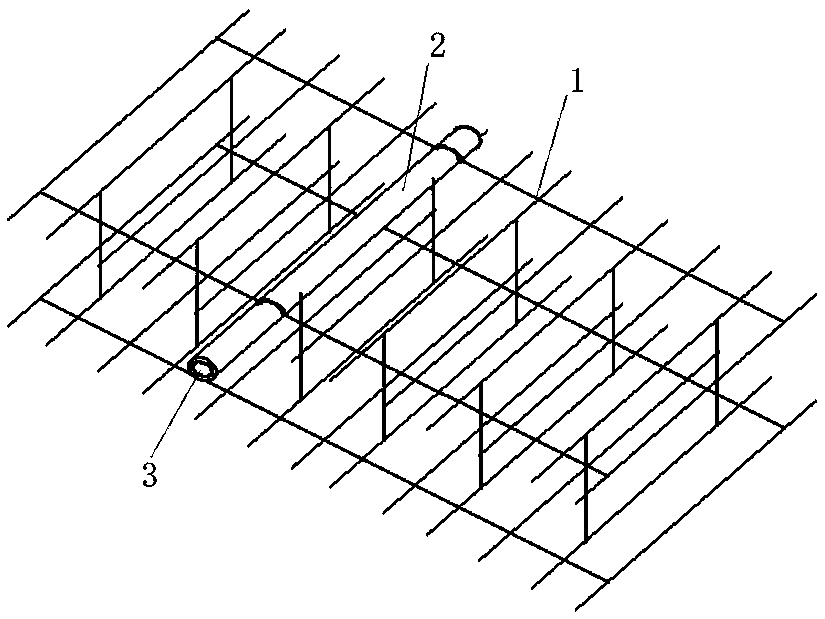

[0015] (2) Check the installation position of the inclinometer tube 2 and the distribution of male and female tubes in sections.

[0016] (3) Hoisting butt joint side inclined pipe 2 and pre-passer test.

[0017] (4) Acquisition of the initial value of the inclinometer data and normalization of the inclinometer data at the pipe bottom and nozzle.

[0018] (5) Data derivation and fitting adjustment at segmented nodes.

[0019] (6) Form a continuous final data report.

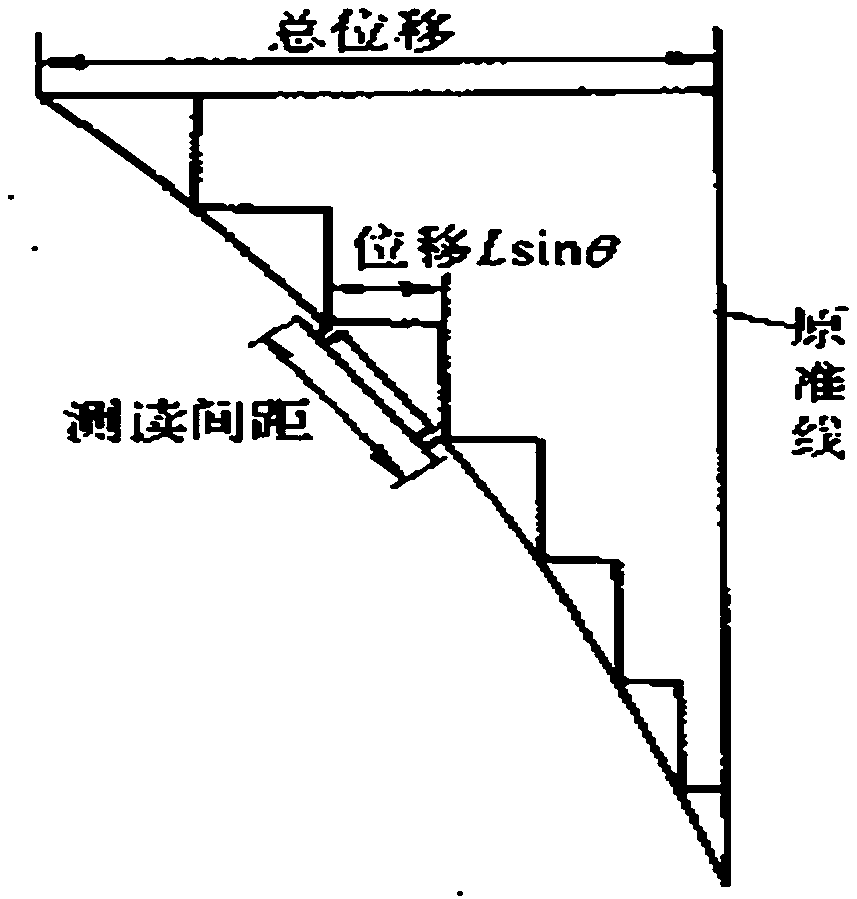

[0020] The present invention lowers the reinforcement cage 1 of the retaining pile (wall) in sections, divides the entire inclinometer tube 2 into at least two sections and places them in the corresponding geometric positions of the reinforcement cage 1, and then rotates at the interface after the reinforce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com