A Method for Measuring the Leakage Inductance at the End of Concentric Winding of AC Motor Stator

A technology of concentric windings and AC motors, applied in the field of analysis and design of AC motors, can solve the problems of lack of acquisition method of end leakage reactance, difficulty in meeting design requirements, long calculation time, etc., and achieves clear physical concept, high speed and simple method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

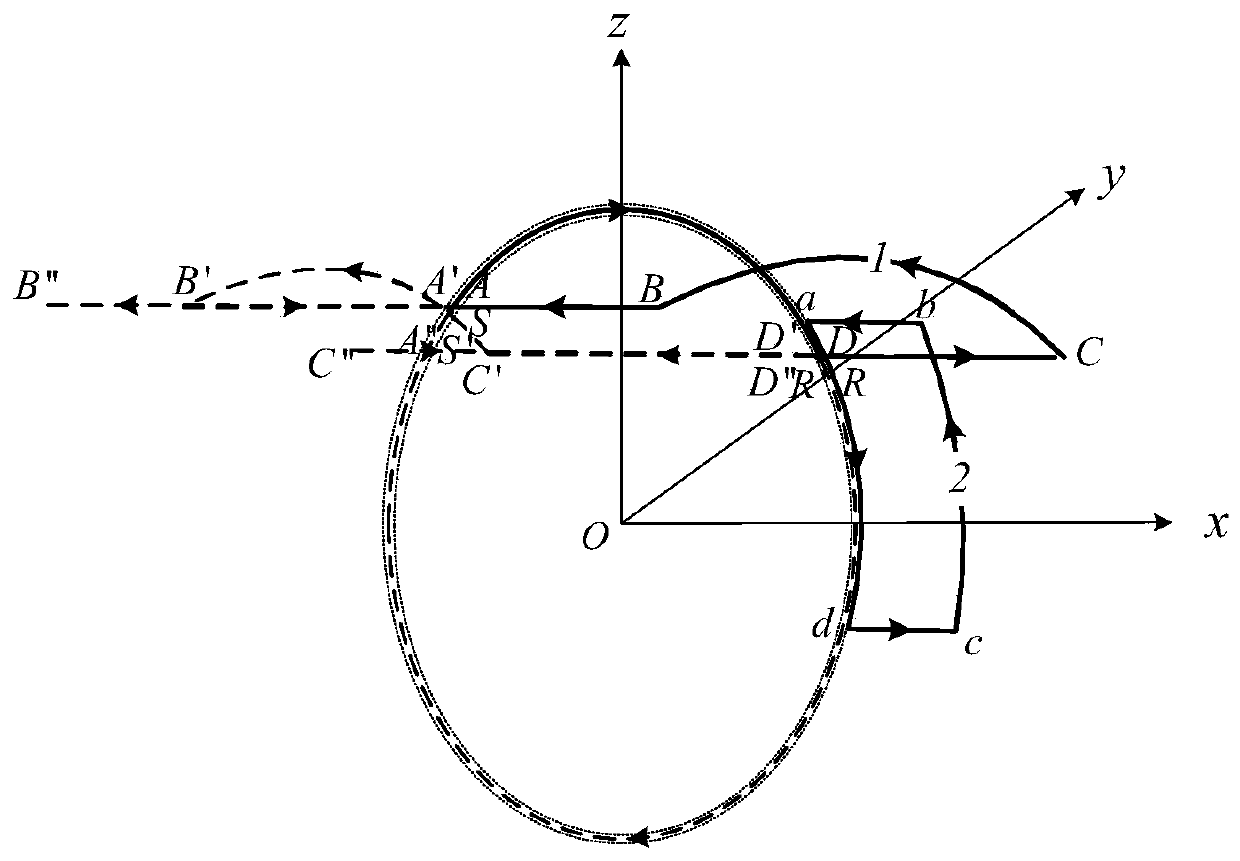

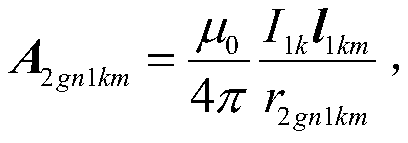

[0020] In this embodiment, the single-layer concentric winding of the stator of an AC motor is selected as an application example, and the specific process of determining the leakage inductance parameters at the end by using the vector magnetic potential is as follows:

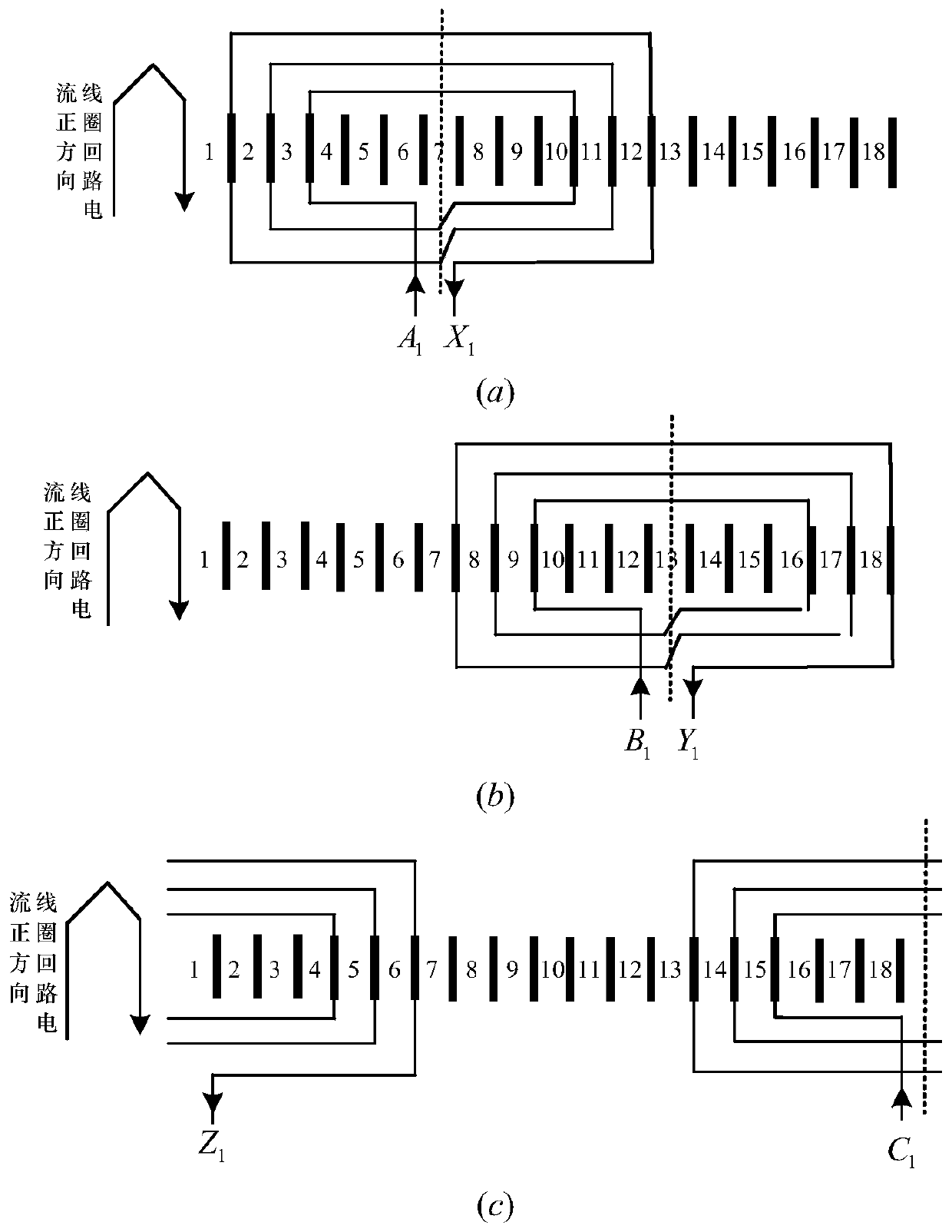

[0021] (1) Distinguish between concentric winding models: figure 1 (a), (b), and (c) are schematic diagrams of the winding coil connection of phase A, phase B, and phase C under a pair of poles; first draw the three-phase winding coil diagrams that should be drawn together in three sub-diagrams It is shown that the selected motor adopts single-layer concentric windings, which are defined as I-type, II-type, and III-type according to the different coil pitches from small to large. figure 1 (a) The connection form of the A-phase winding coil, the slot numbers of the two coil sides of the I-shaped coil are 3 and 10 respectively, and the pitch y I It is equal to 7; the slot numbers of the two coil sides of the Ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com