Workshop equipment monitoring system based on Powerlink

A technology of workshop equipment and monitoring system, applied in the field of workshop equipment monitoring system, can solve the problems of lack of real-time control and determinism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

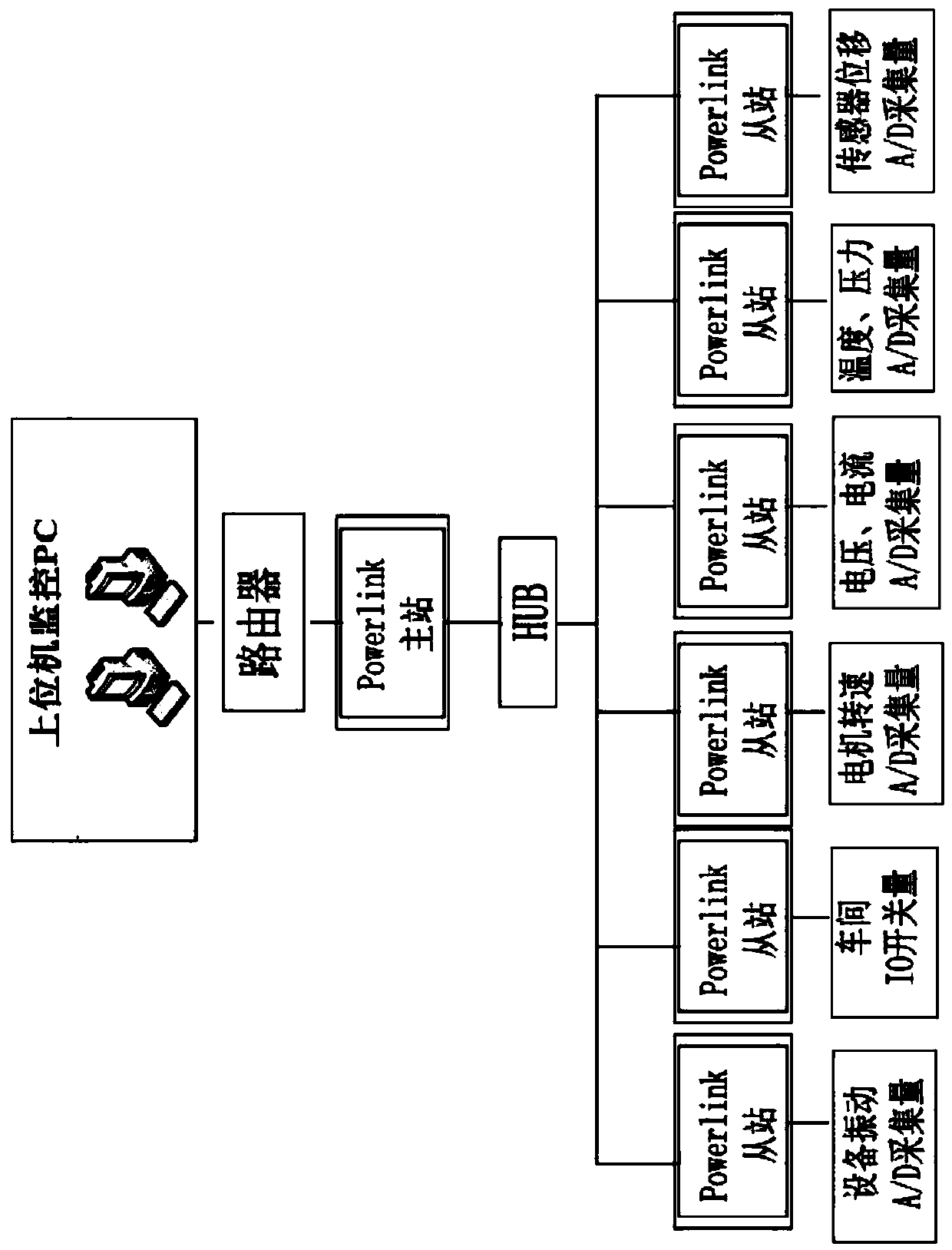

[0023] Embodiment 1, with reference to figure 1 , a workshop equipment monitoring system based on Powerlink, which is mainly composed of an upper computer monitoring PC, a Powerlink master station and a lower computer data acquisition slave station (referred to as a Powerlink slave station or a slave station); a Powerlink master station and each lower computer data acquisition slave station The Powerlink bus is used to communicate between them; the Powerlink master station issues start instructions to each slave data acquisition station of the lower computer, and processes the recorded workshop equipment voltage, current, temperature, speed, vibration, pressure, sensor displacement, and switch transmitted on the Powerlink bus in real time. Quantity, workshop environment variables and power quality operating parameters, monitor the real-time operation status of workshop equipment, all data is stored on the server, and realize automatic equipment failure alarm and control the act...

Embodiment 2

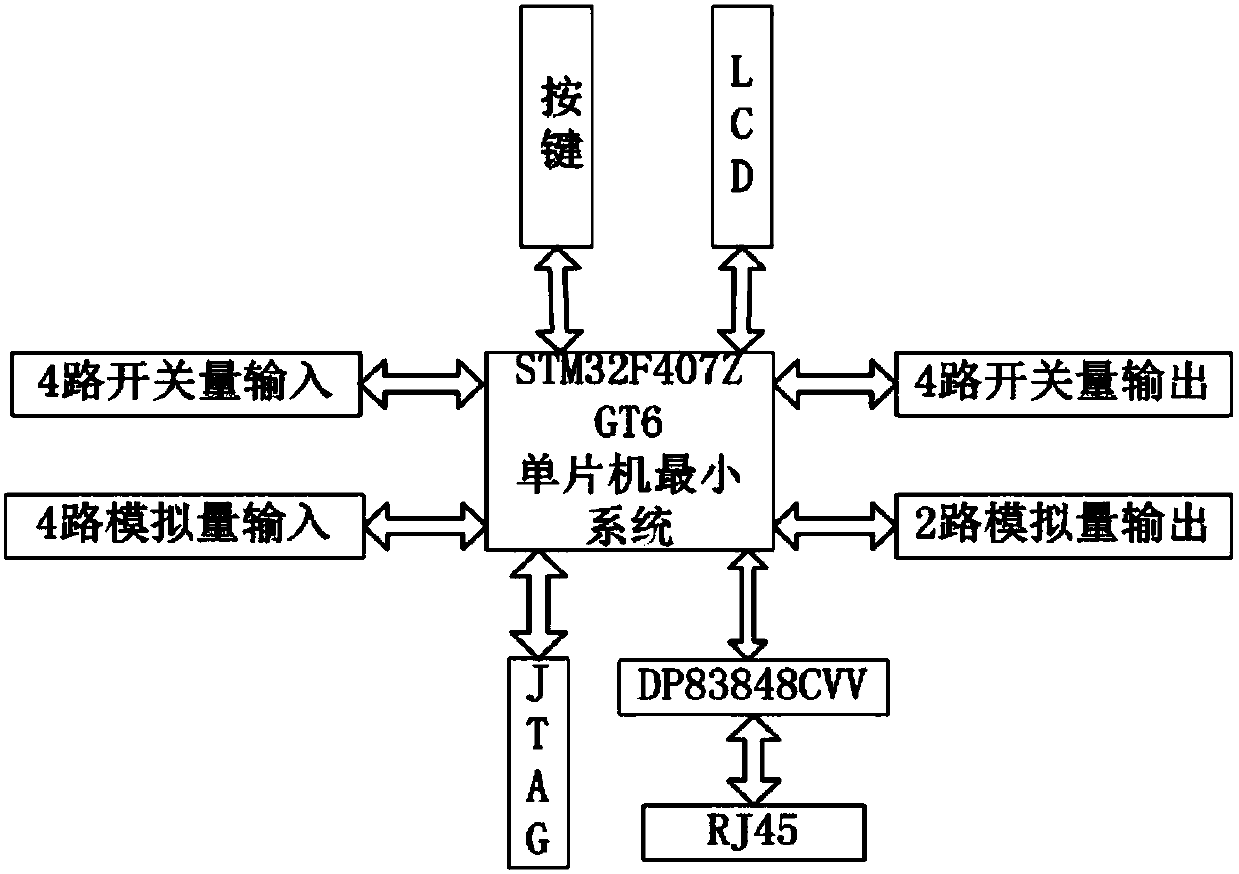

[0024] Embodiment 2, with reference to figure 2 , a kind of workshop equipment monitoring system based on Powerlink described in embodiment 1, the controller of the Powerlink master station uses the minimum system of STM32F407ZGT6 single-chip microcomputer as the core component, and the minimum system of STM32F407ZGT6 single-chip microcomputer is connected with onboard buttons, LCD, and 4 switches Input, 4-way switch output, 4-way analog input, 2-way analog output, JTAG debugging interface; 4-way analog input is used as the input port for temperature and pressure acquisition, and 8-way switch value input and output are used as I / O equipment group Communication port for control signals.

[0025] The workshop equipment monitoring system mainly completes the data acquisition task of the state variables in the workshop equipment operation process. Specifically include: motor voltage and current, equipment temperature, motor speed, vibration frequency, etc., as well as some statu...

Embodiment 3

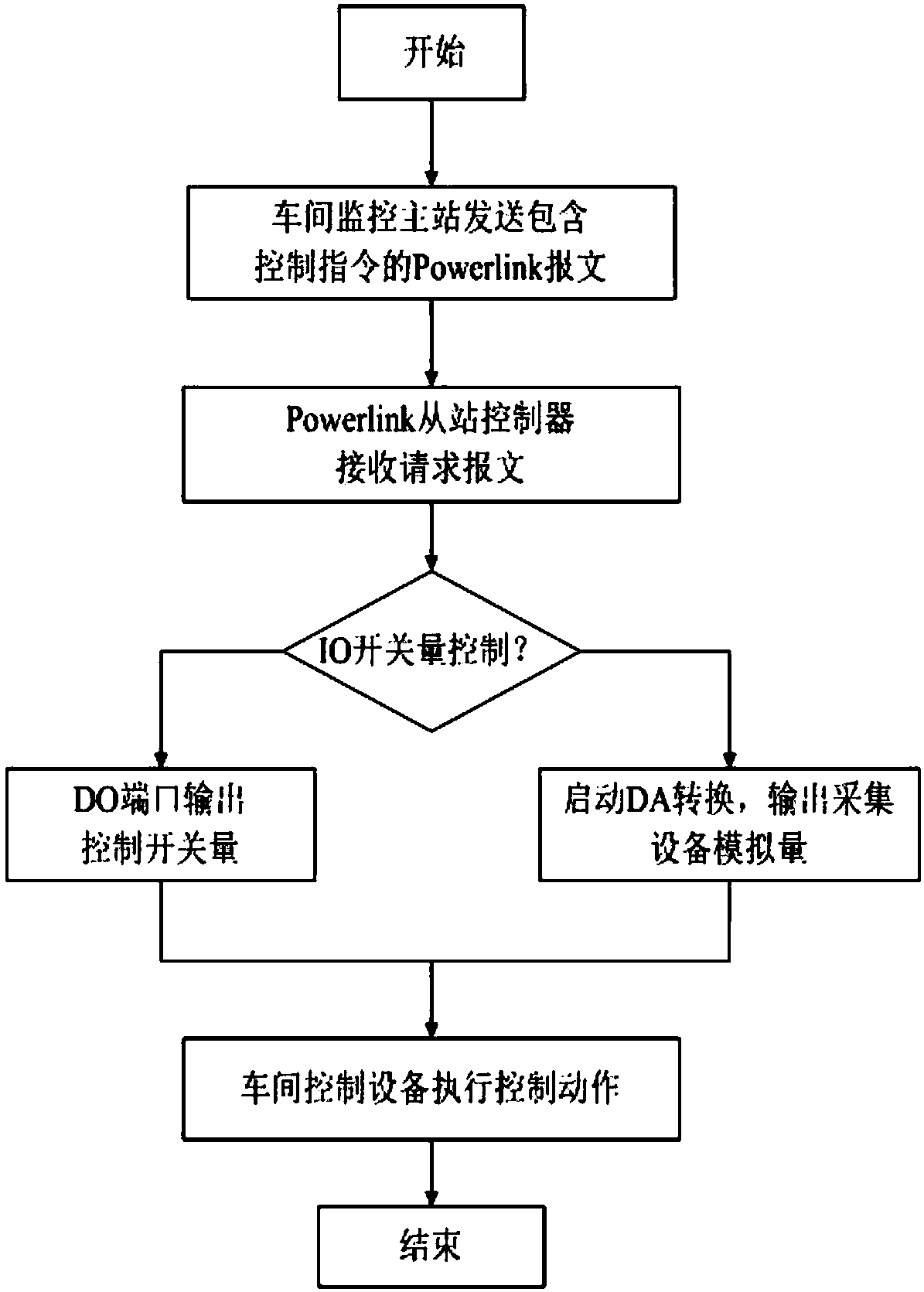

[0027] Embodiment 3, in a kind of Powerlink-based workshop equipment monitoring system described in Embodiment 1 or 2: the Powerlink protocol stack transplantation of the Powerlink master station controller and the lower computer data acquisition slave station controller: the transplantation of Powerlink is divided into master station The protocol stacks of the controller and the slave station controller are transplanted separately, mainly including: the modification of the network card driver, the configuration of the object dictionary, and the configuration of the timer part; the network data of the master station is triggered by a high-precision clock, and the timing is carried out with the slave station. Data interaction and execution of IO operations; Powerlink master-slave stations directly use the form of master station polling slave stations to transmit real-time synchronous data, and transmit non-real-time ordinary data in the latter part of a cycle; Powerlink communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com