PDVF coating method for battery separator

A battery diaphragm and coating technology, which is applied in the field of PDVF coating of battery diaphragm, can solve the problems of increasing ionic resistance, reducing battery energy density, weak interaction, etc., and achieve the goal of reducing equilibrium time, increasing conductivity and improving performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: a kind of PVDF coating method of battery separator, it comprises the following steps:

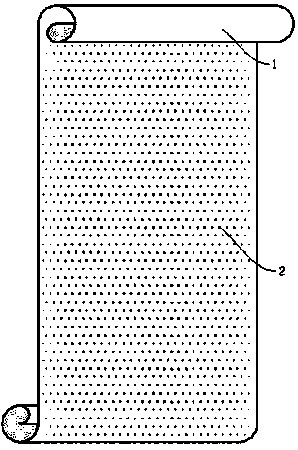

[0043] Such as figure 1 As shown, prepare a rollable battery separator base layer 1 and lay it flat.

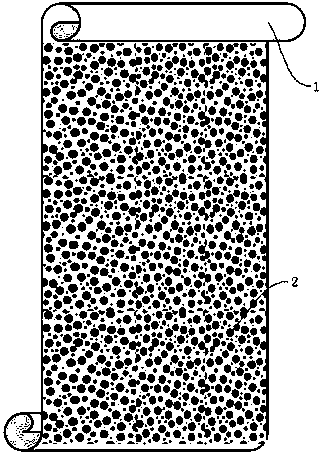

[0044] Then prepare some PVDF particles, the diameter of PVDF particles is 10 2 ~10 3 between nm. Then add an appropriate amount of water to the PVDF particles to form a suspension of PVDF particles.

[0045] The PVDF particle suspension is added to the ultrasonic atomizer to form a number of droplets carrying PVDF particles, and the droplets are sprayed towards the surface of the battery separator base layer 1 through the atomization nozzle, or the droplets are thrown towards the surface of the battery separator base layer 1 . In this way, the PVDF particles are sprayed on the surface of the battery diaphragm by a non-contact spraying method.

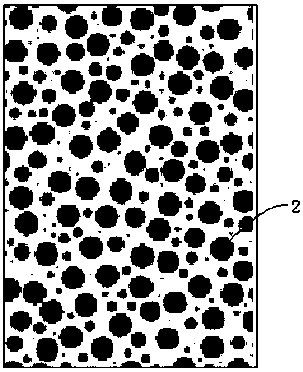

[0046]During the spraying process, the base layer 1 of the battery separator needs to be pulled to make it reciprocate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com