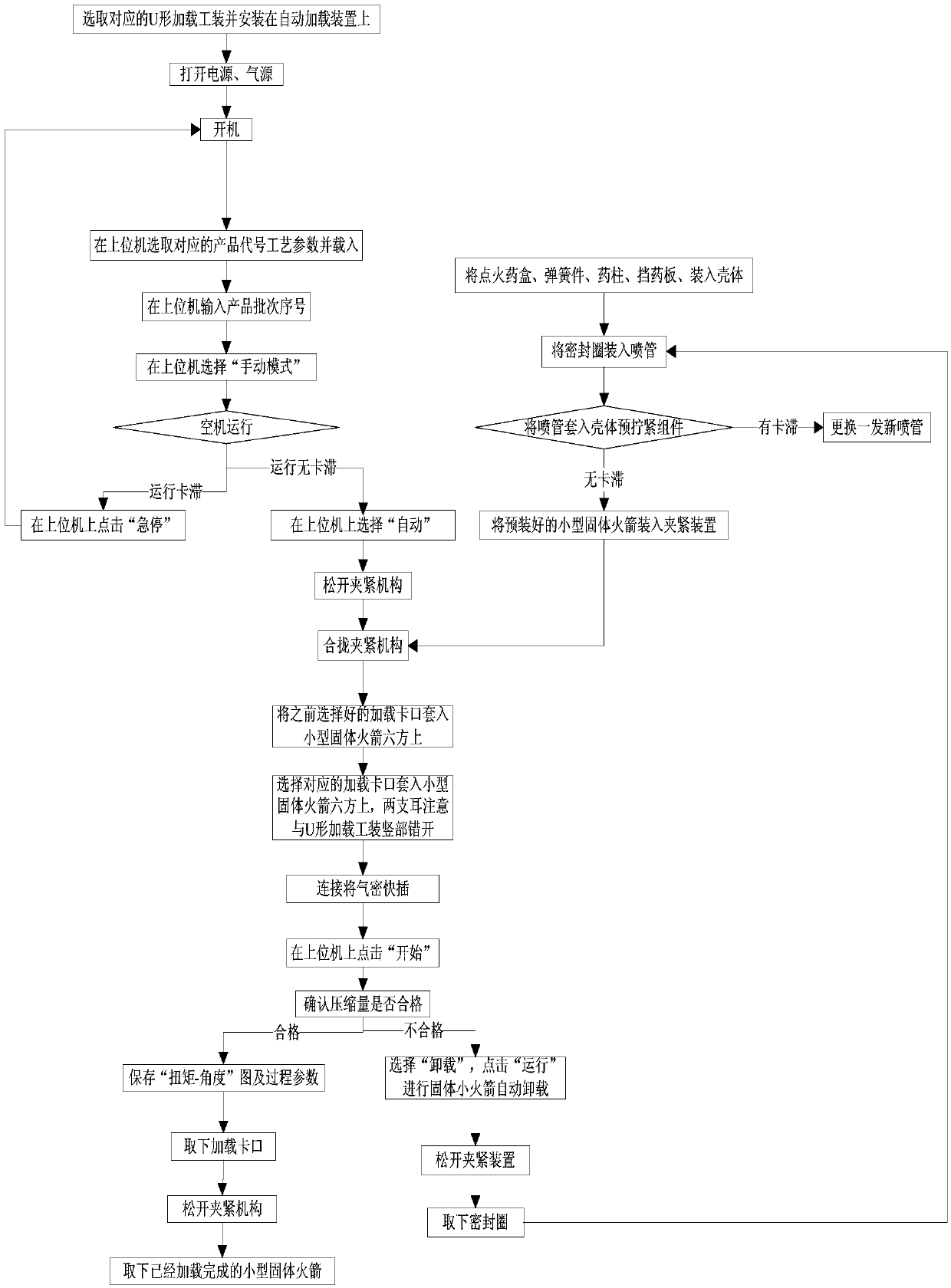

A method and device for automatic loading of small solid rockets based on compression amount control

A solid rocket, automatic loading technology, used in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of low intrinsic safety, backward recording methods, low assembly efficiency, etc., to eliminate operational safety risks and compression. Consistency guarantee, the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

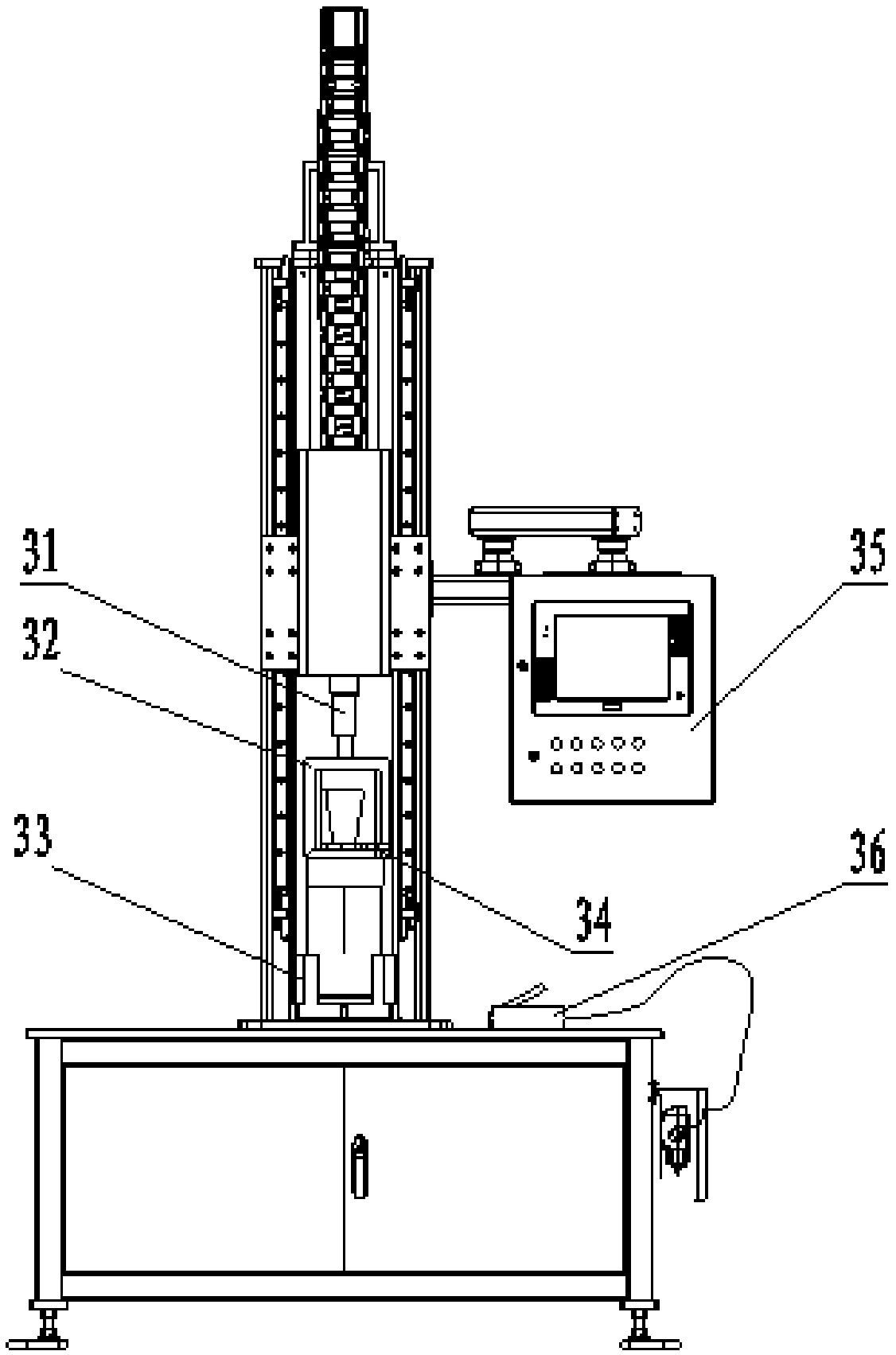

[0056] Such as image 3 As shown, the method of the present invention is based on a kind of small-sized solid rocket assembly automatic loading and online airtight detection device (i.e. the loading device for loading small-sized solid rocket), which device includes: clamping mechanism (33), sliding table mechanism, tightening Mechanism, U-shaped loading tooling (32), loading bayonet (34, 41), upper seat, base, airtight detection mechanism (36), master control module (35);

[0057] The clamping mechanism is fixed on the base to clamp the bottom of the solid rocket;

[0058] The U-shaped loading tool can load the solid rocket directly or through the loading bayonet;

[0059] The tightening mechanism is fixed on the sliding table mechanism through one end of the screw, and the other end is connected to the U-shaped loading tool;

[0060] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com