Sheet binding device and sheet post-processing apparatus

A post-processing and sheet material technology, which is applied in the direction of bookbinding, thin material processing, and electrical recording process equipment using charge patterns, etc., can solve the problem of reduced joint force, achieve increased joint force, easy adjustment, and suppress unevenness The effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

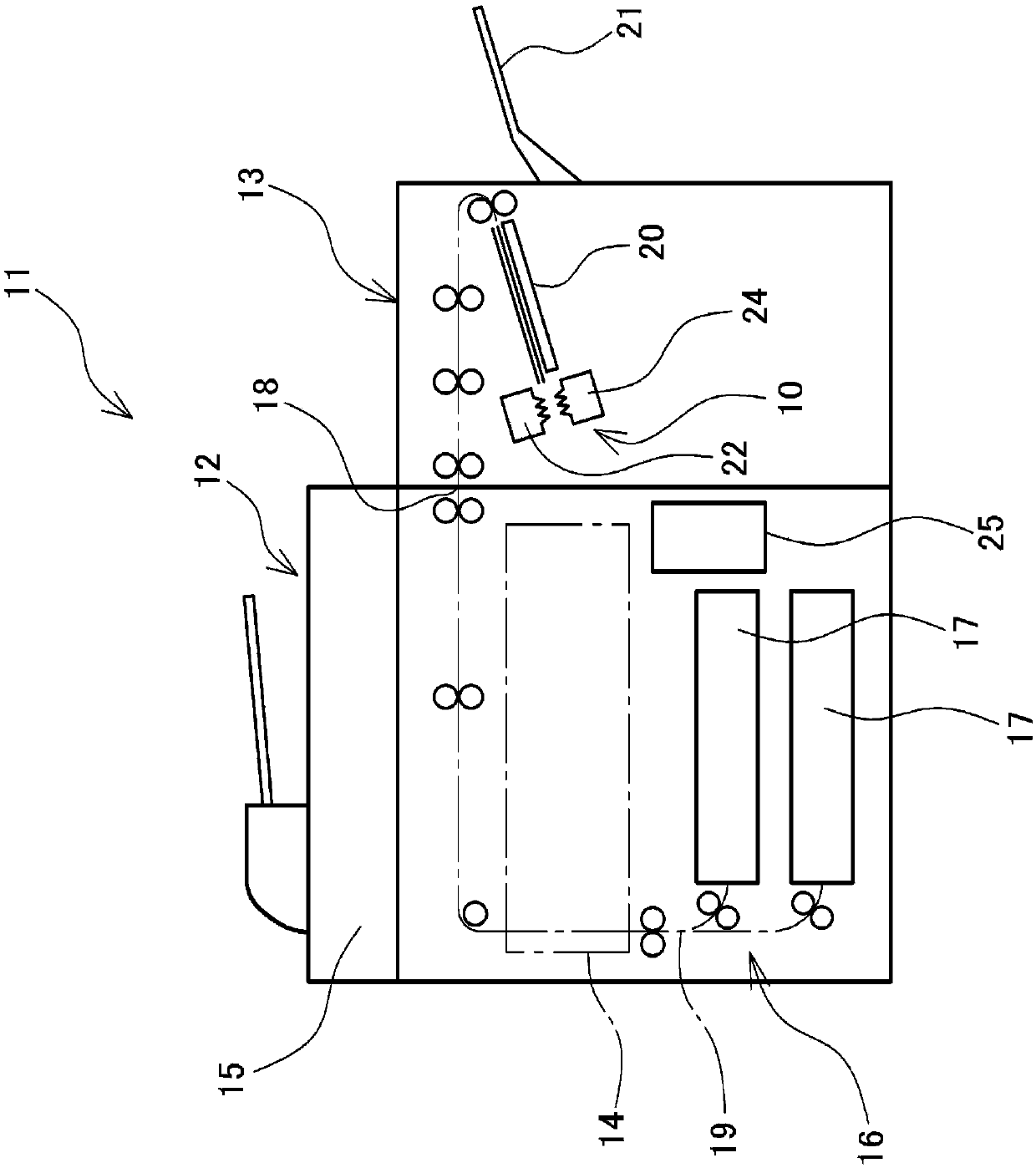

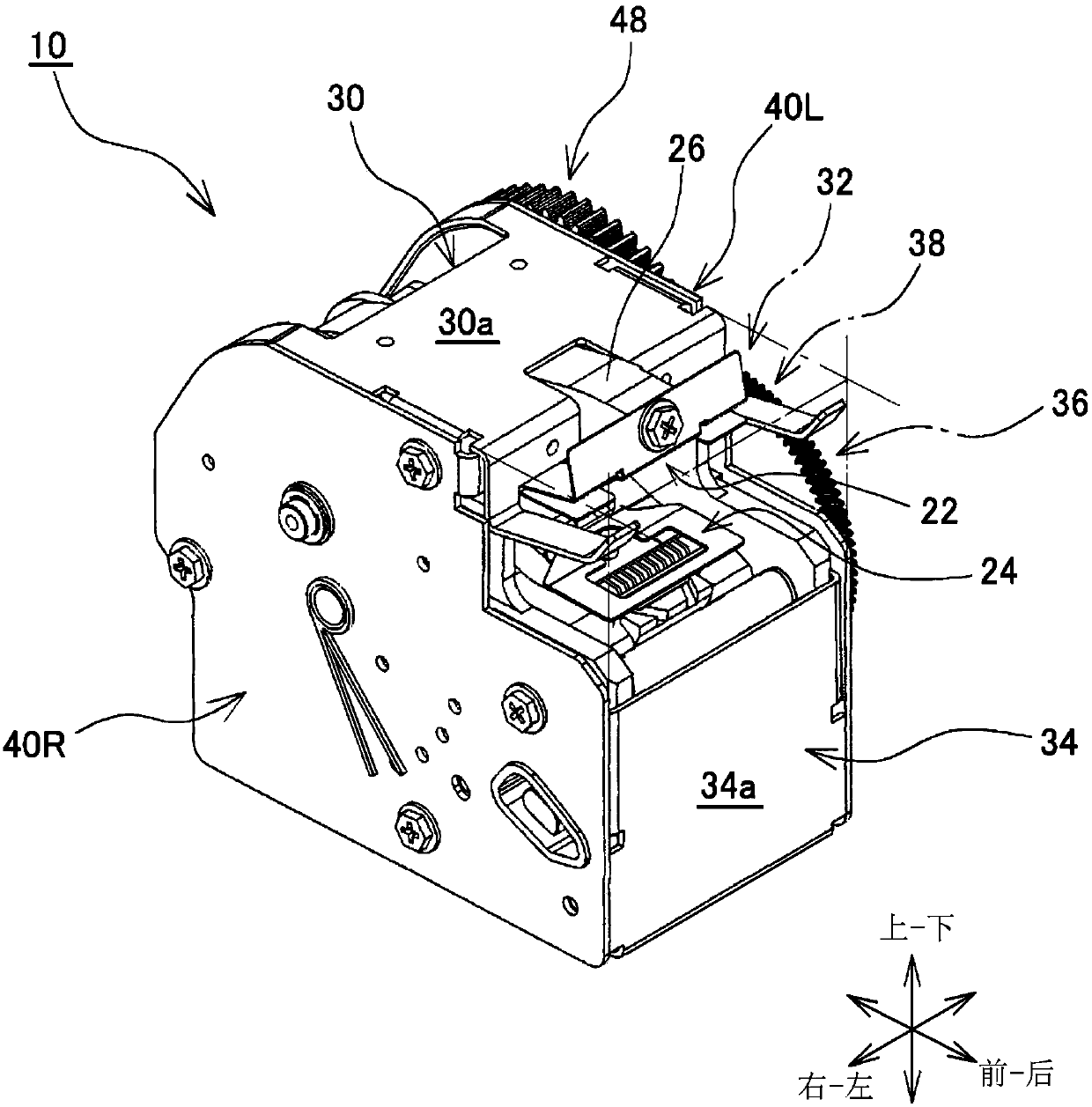

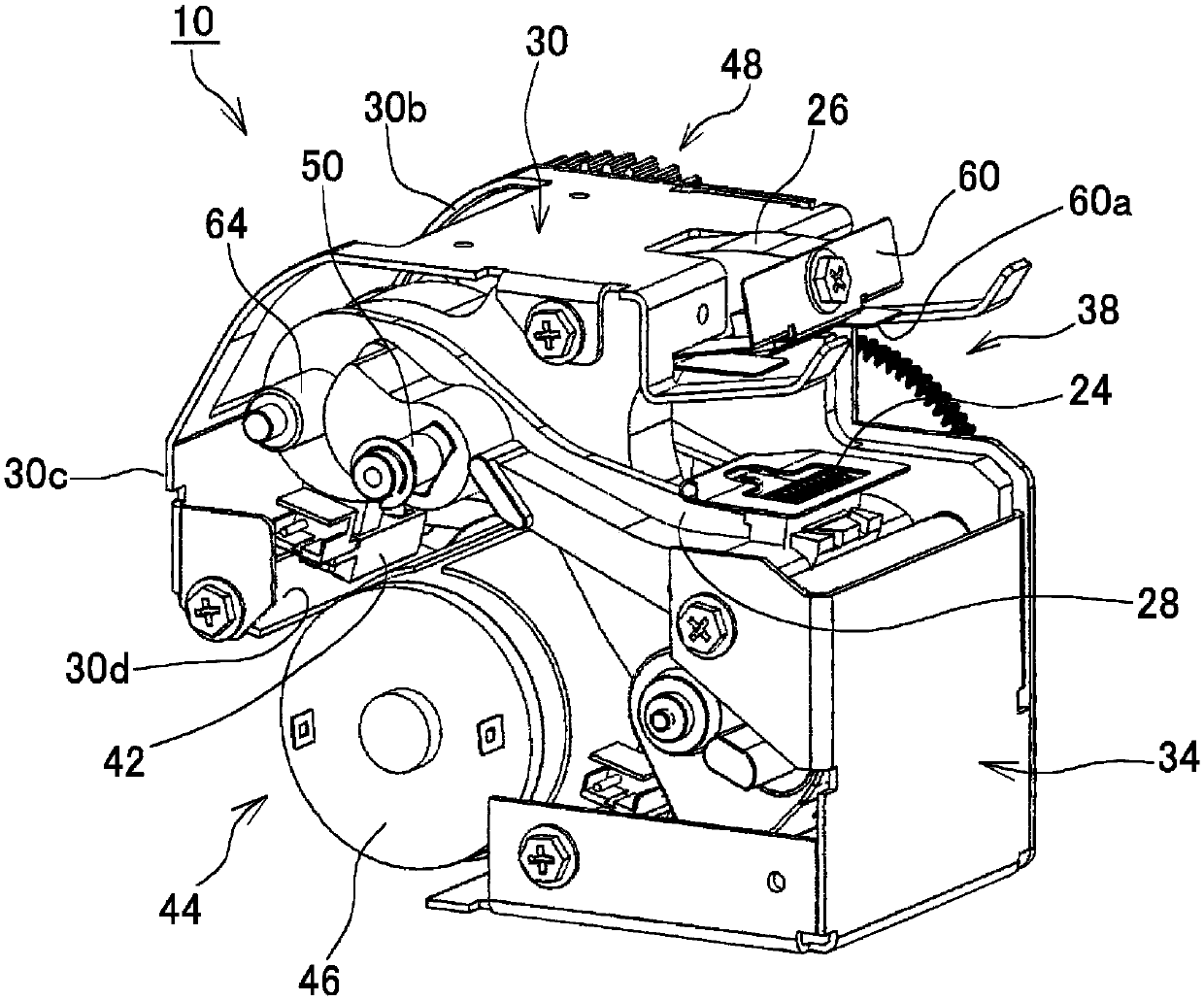

[0033] Exemplary embodiments of the present invention will be described below with reference to the accompanying drawings. figure 1 is a schematic diagram showing an overall configuration of an image forming system 11 including a recording material binding apparatus 10 according to the exemplary embodiment. The image forming system 11 includes: an image forming apparatus 12 having a printing function and a copying function using, for example, electrophotography; After being formed on the recording material, post-processing such as punching and stapling is performed on the recording material. The recording material binding apparatus 10 of the exemplary embodiment may be installed in a recording material post-processing apparatus 13 .

[0034] The image forming apparatus 12 includes an image forming section 14 that forms a toner image based on the acquired document information. The document information may be acquired by reading a document with the document reading unit 15 pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com