Precast pile with reliable axial-direction stressing performance

An axial stress, prefabricated pile technology, applied in sheet pile wall, construction, foundation structure engineering and other directions, can solve problems such as changes in the performance of prefabricated piles, and achieve the effect of avoiding defective piles, strengthening stress and ensuring performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

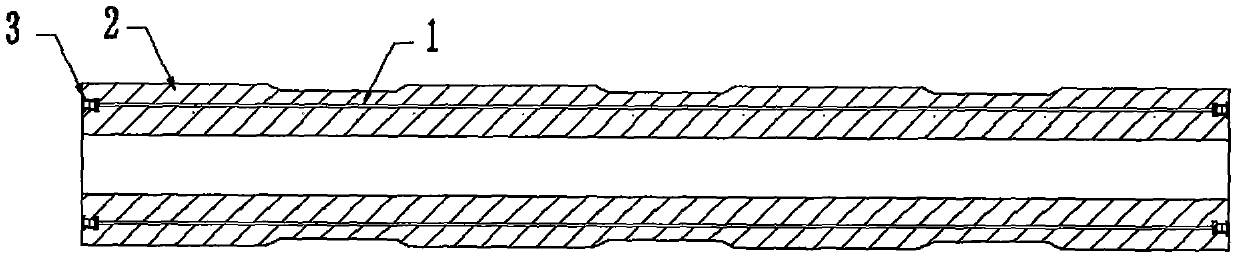

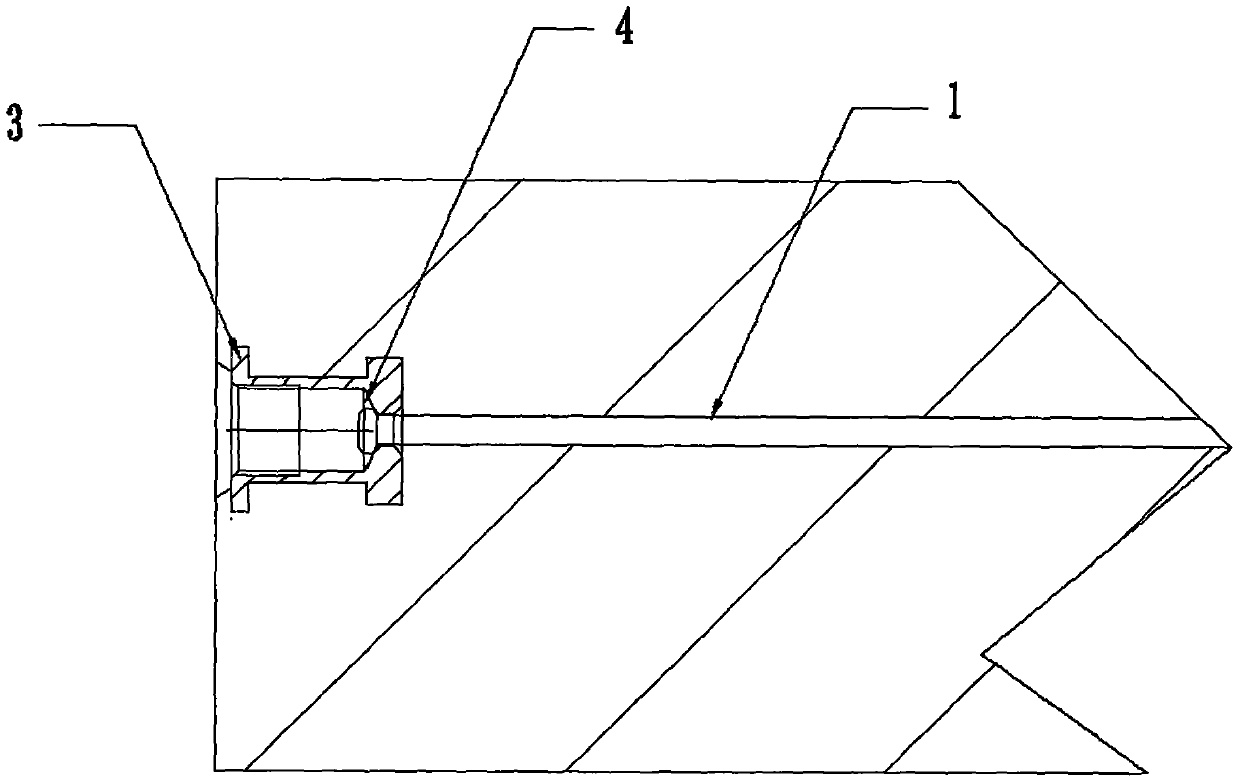

[0017] Such as Figure 1-2 As shown, a prefabricated pile with reliable axial stress performance of the present invention includes a main reinforcement 1 and a pile body 2, and special-shaped nuts 3 are arranged at both ends of the pile body 2, and a clamping platform 4 is arranged in the special-shaped nut 3, and the special-shaped nut 3 is connected with the main rib 1 through the card table 4, the outer circle of the special-shaped nut 3 is enlarged and has a concave-convex surface, and the special-shaped nut 3 is fixedly connected with the card table 4.

[0018] In this embodiment, the special-shaped nut 3 is welded to the main rib 1 through the clamping platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com