Remote running error correction method for intelligent gas meters

A technology for remote calibration and gas meters, which is applied in the direction of testing/calibration devices, measuring devices, instruments, etc., can solve the problems of undiscovered published patent documents, procurement, increased maintenance costs, and high maintenance costs, achieving significant economic benefits and social Benefits, reduce marketing and operating costs, and save operating and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below with reference to the drawings and specific embodiments. The following embodiments are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

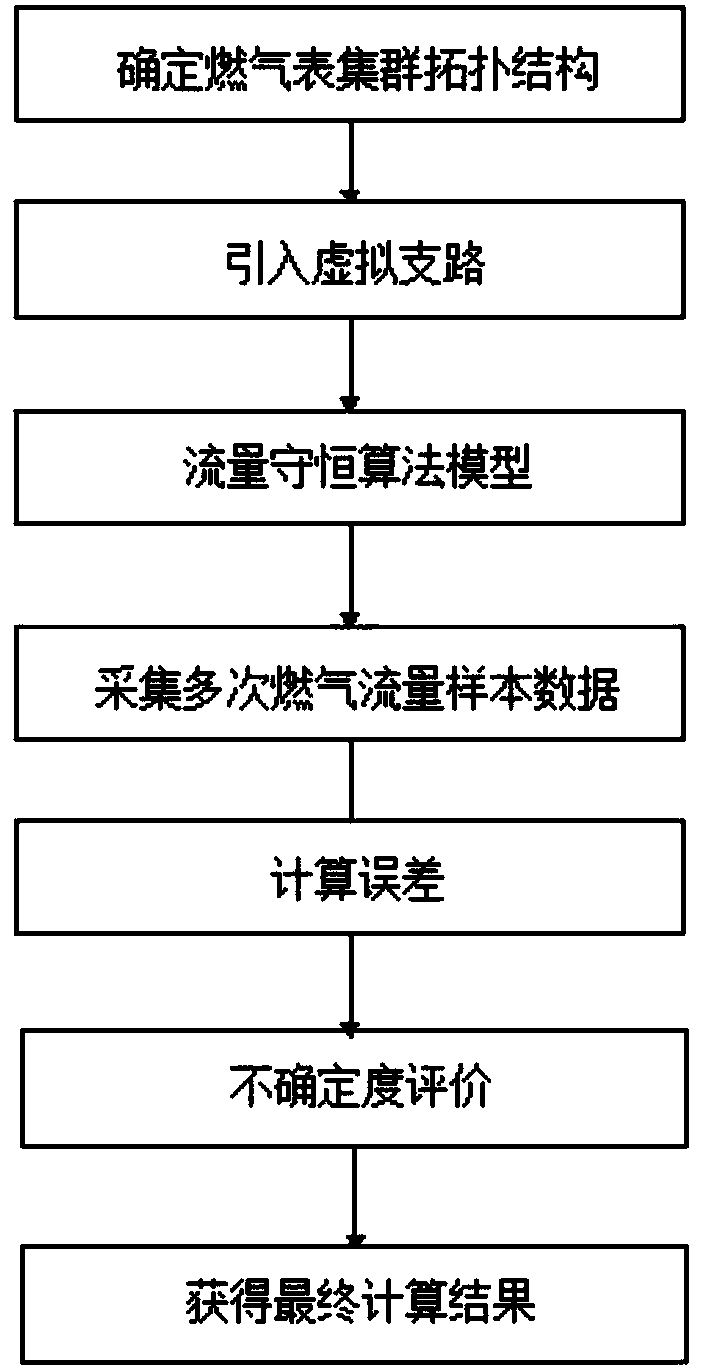

[0032] A remote calibration method for operating errors of a smart gas meter. The specific steps of this method are:

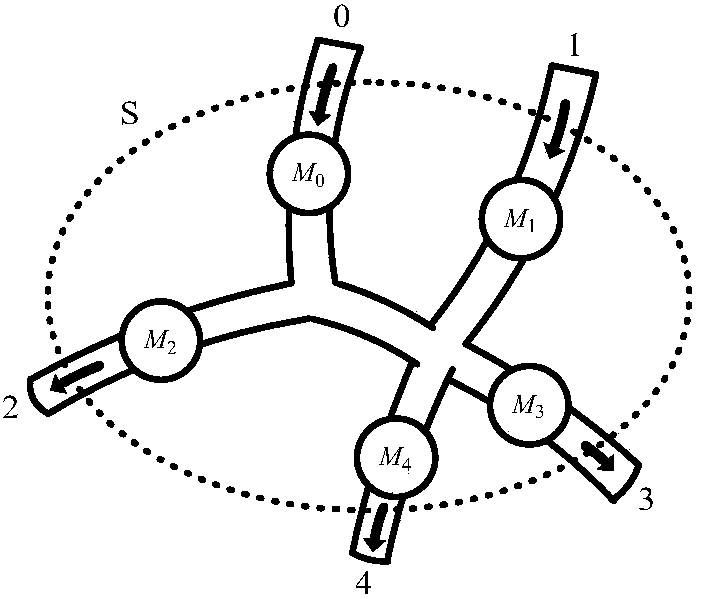

[0033] ⑴The installation of the smart gas meter cluster forms a tree topology, which can remotely obtain the total meter and the flow data of each sub-meter in the smart gas meter cluster;

[0034] ⑵According to the tree topology structure formed by the smart gas meter cluster, obtain the basic flow conservation model of the smart gas meter cluster;

[0035] (3) Correct the line loss error, introduce virtual branches to dynamically modify the topology model of the smart gas meter cluster, and at the same time modify the basic flow conservation model to obtain the flow conservation algorithm model;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com