Multifunctional fixture mechanism for steel wire ropes

A steel wire rope, multi-functional technology, applied in the field of steel wire performance testing devices, can solve problems such as single function, and achieve the effect of convenient packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

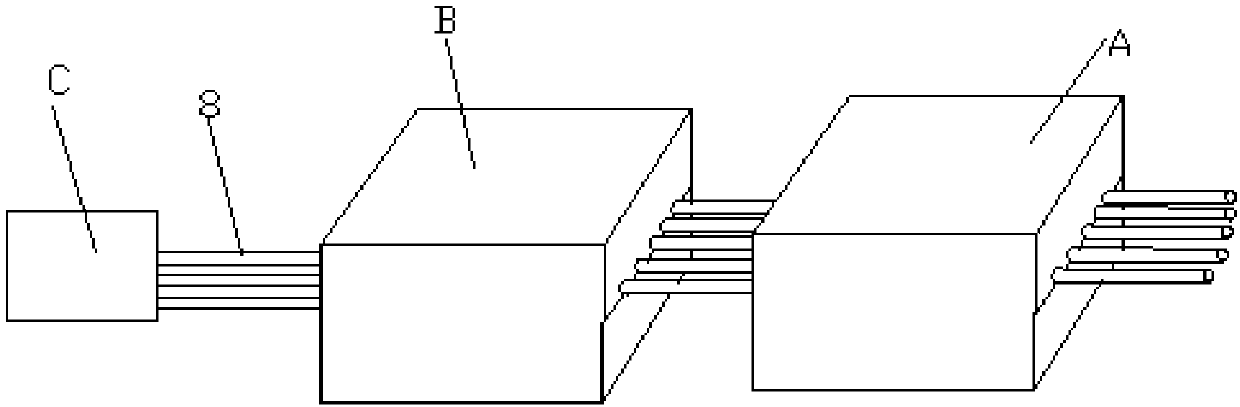

[0031] Such as figure 1 Shown is a multifunctional clamp mechanism for steel wire ropes, including a steel wire clamp, a tractor, a gathering clamp and a wire rope binding machine;

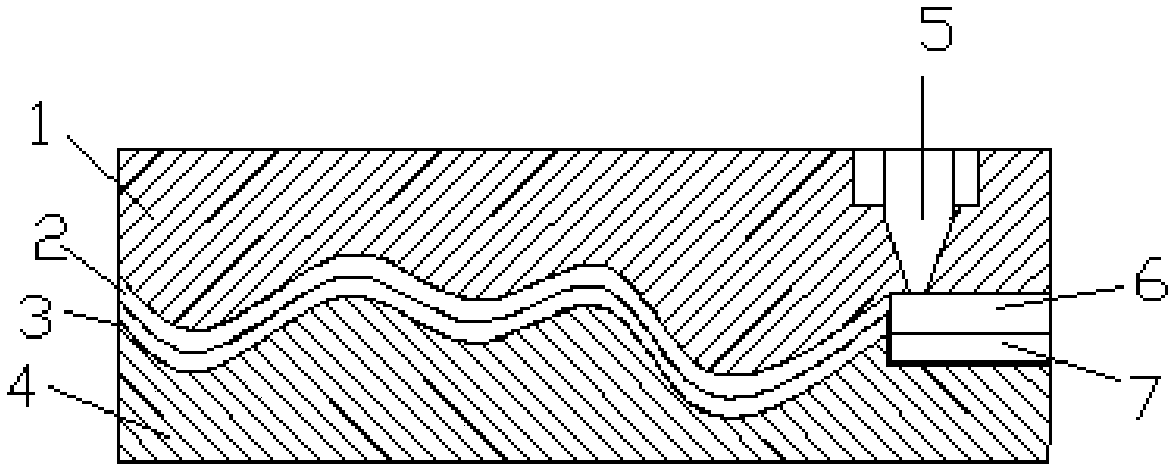

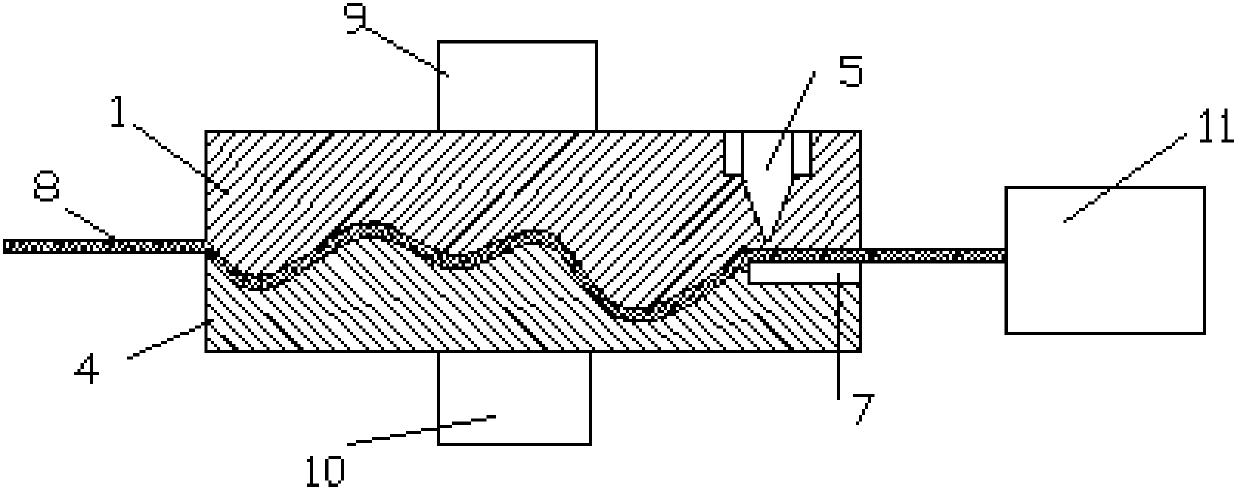

[0032] Wire clamps (such as Figure 2-6 shown) includes an upper fixture and a lower fixture. The upper fixture is provided with several first grooves arranged side by side, and the lower fixture is provided with several second grooves arranged side by side. The first grooves and the second grooves can be jointly form a clamping cavity for the steel wire to pass through; specifically, the lower surface of the upper clamp includes a first curved surface with several different radians, and the first groove is arranged along the length direction of the first curved surface; the upper surface of the lower clamp is provided with a a second curved surface with the same curved surface, and the second grooves are arranged along the length direction of the second curved surface;

[0033] One end of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com