Cold pool flow channel capable of effectively improving safety of pool type lead-cooled fast reactor

A safety and cold pool technology, applied in the direction of climate sustainability, reactors, cooling devices, etc., can solve the problems that thermal inertia cannot be effectively used, is not conducive to the safety of lead-cooled fast reactors, and introduces positive reactivity into the core. , to achieve the effect of improving system reliability, reducing construction cost and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

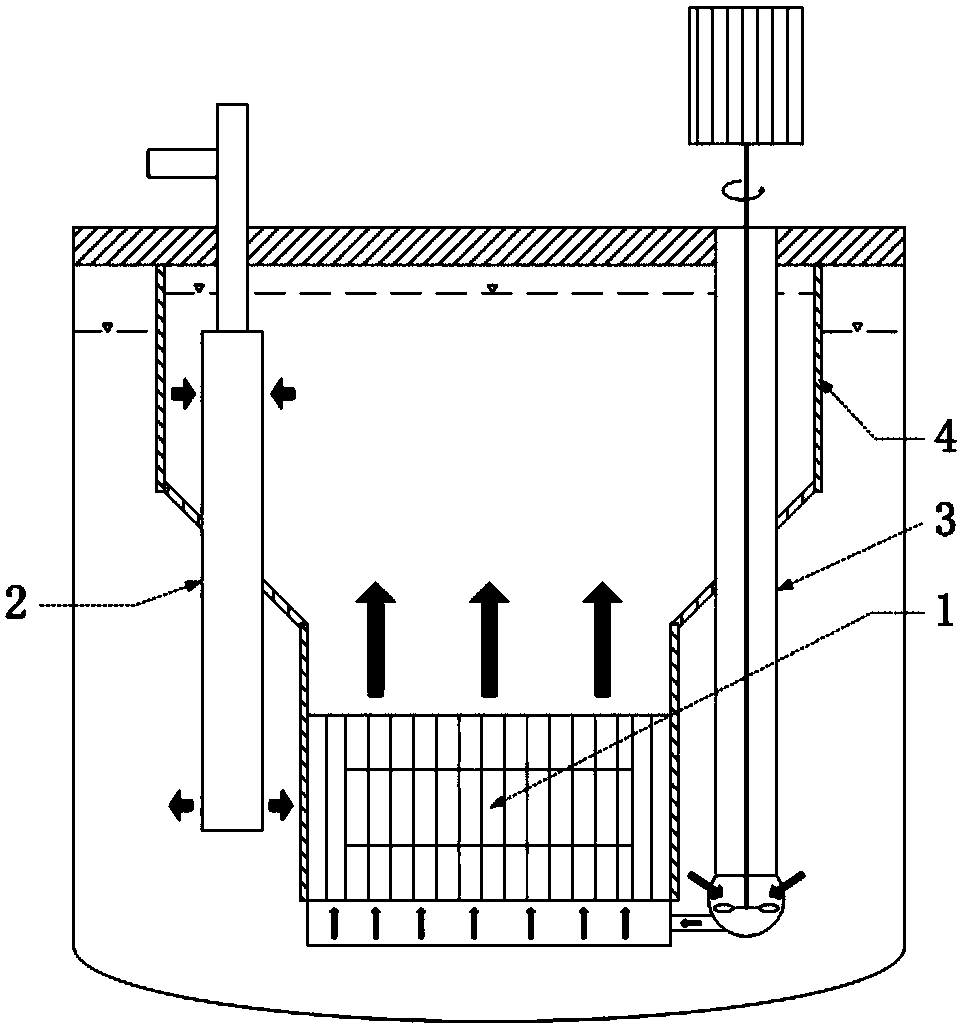

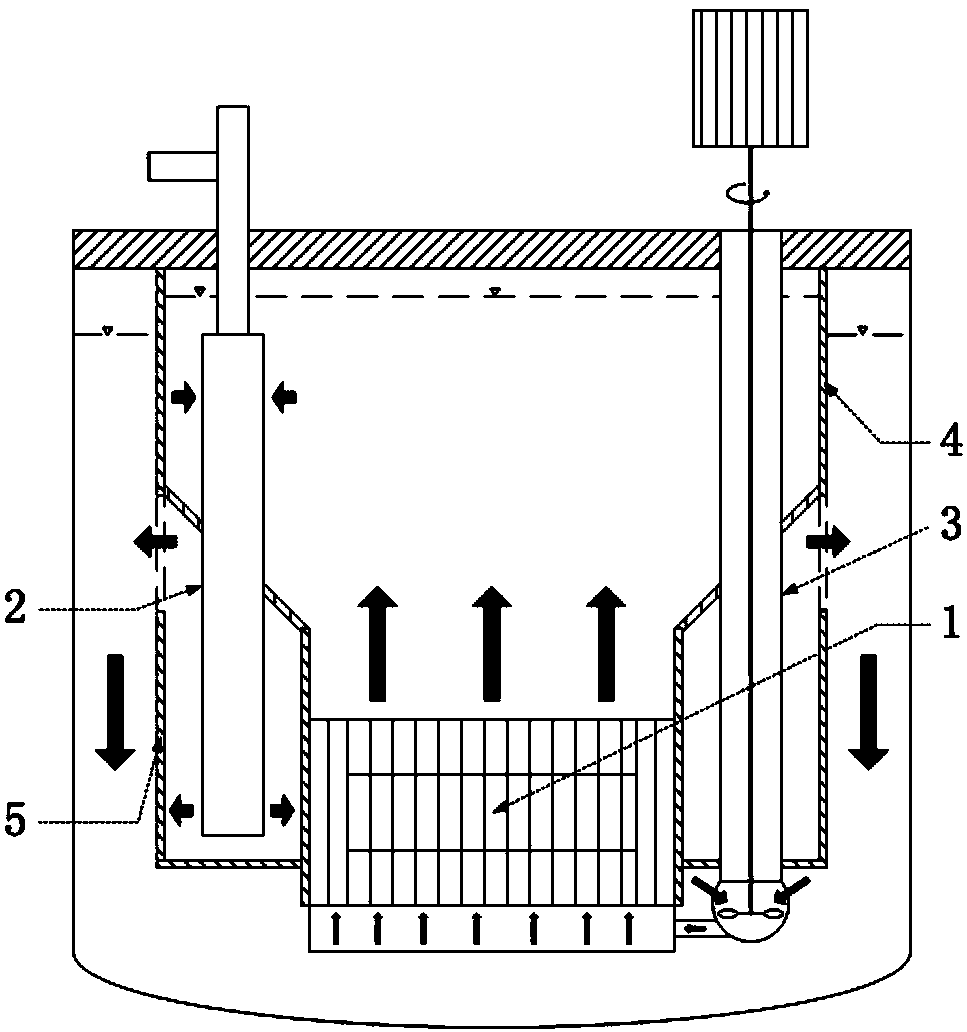

[0020] Such as figure 2 As shown, the present invention provides a cold pool runner design that can effectively improve the safety of the pool-type lead-cooled fast reactor. In typical scheme design (such as figure 1 Shown) on the basis of the increase of the cold pool secondary partition orifice 5 to redesign the cold pool flow channel.

[0021] The design life of the secondary partition orifice plate 5 of the cold pool takes the reactor lifetime as a reference, and there is no need to replace it during the reactor lifetime.

[0022] The cold pool secondary partition orifice 5 is used in the cold pool to separate the outlet of the main heat exchanger 2 and the inlet of the coolant core 1, thereby forming a new cold pool coolant flow channel. After the coolant flows out of the heat exchanger, it no longer flows directly to the core inlet, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com