Static sealing self-quench-preventing high-temperature superconducting motor

A high-temperature superconducting and static technology, applied in the usage of superconductor elements, electrical components, electromechanical devices, etc., can solve problems such as quenching of high-temperature superconducting windings, achieve increased electrical load, reduce weight, reduce manufacturing difficulty and operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

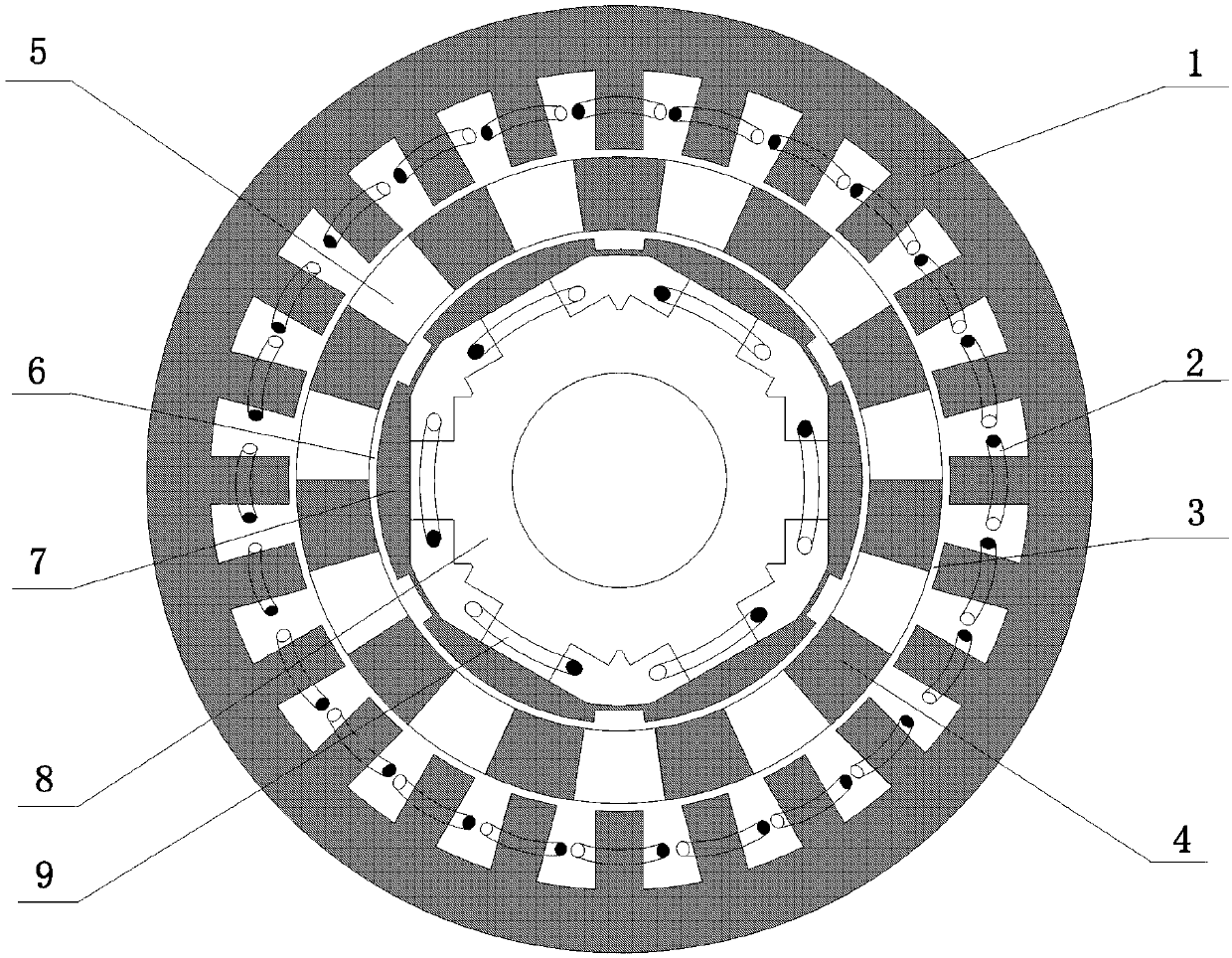

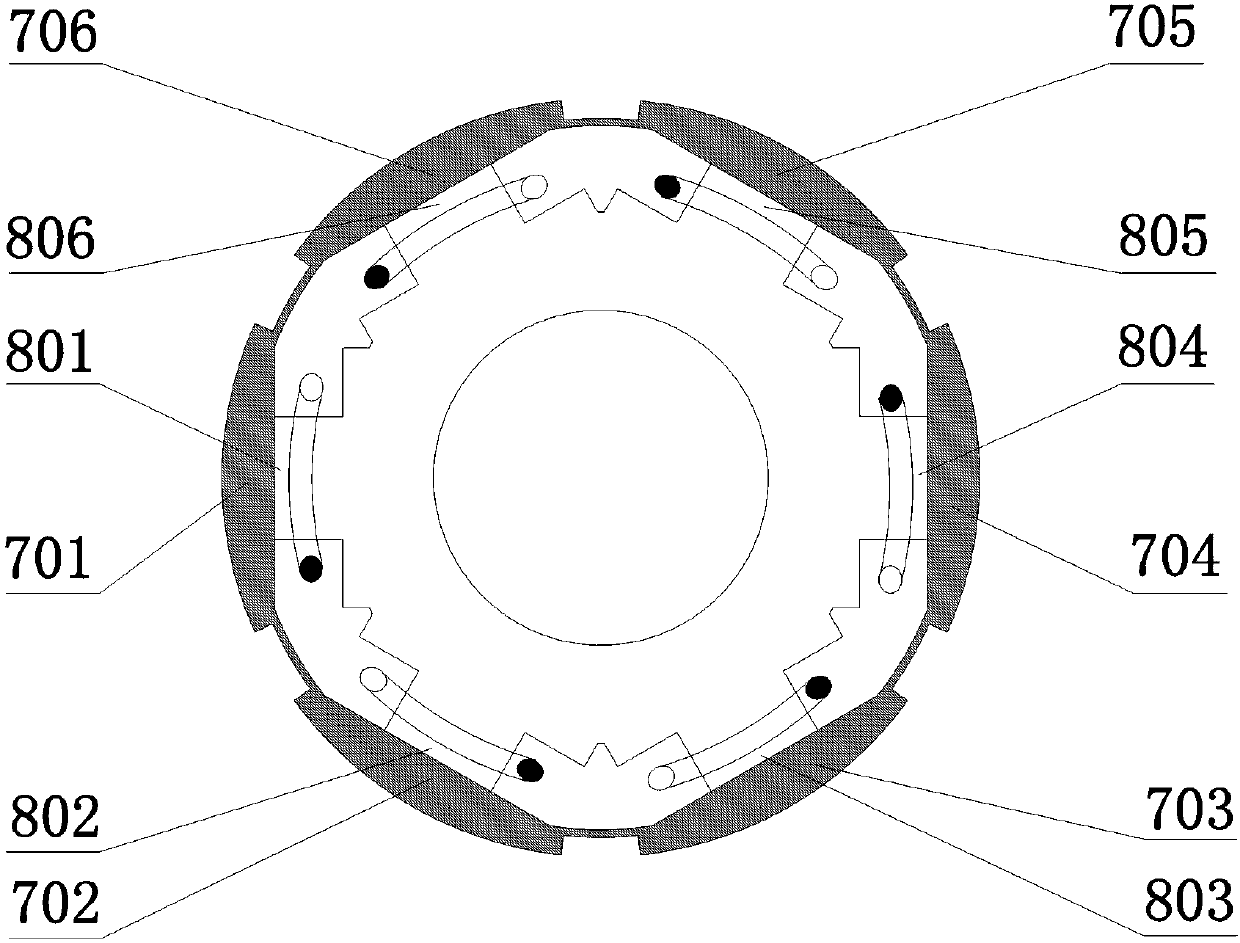

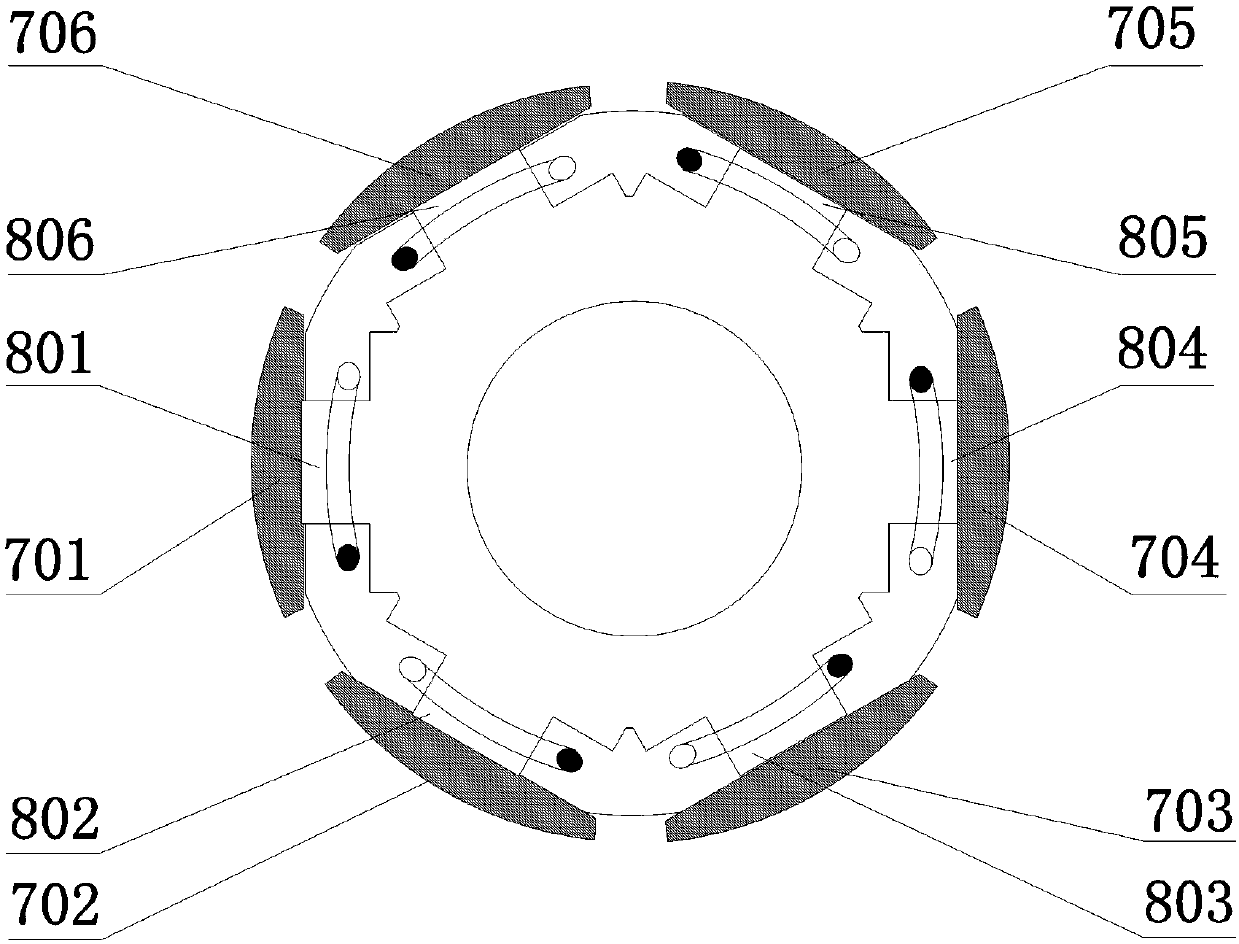

[0020] .A statically sealed self-prevention loss ultra-high temperature superconducting motor, such as figure 1 As shown, it includes an outer stator, a rotor and a high-temperature superconducting excitation inner stator arranged concentrically from the outside to the inside; there is a first air gap 3 between the outer stator and the rotor, and the high-temperature superconducting excitation inner stator and the rotor There is a second air gap 6 between them; the outer stator includes an outer stator core 1 and an armature coil 2 fixed on the inner surface of the outer stator core 1, and 24 stator teeth are uniformly arranged on the inner surface of the outer stator core 1, corresponding to Grooves are formed between the adjacent stator teeth. The outer stator includes 24 armature coils 2; The pivot coils are connected according to certain rules to form a three-phase symmetrical winding. The rotor includes 11 conductive core blocks 4 and 11 non-magnetic material blocks 5 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com