Ultrasonic power supply and control method

An ultrasonic and power technology, applied in electrical components, continuously variable inductors/transformers, output power conversion devices, etc., can solve the problem of fixed frequency or limited frequency range, waste of resources, low ultrasonic energy transfer efficiency, etc. problems, to achieve the effect of wide range of use, high energy utilization, constant specific power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

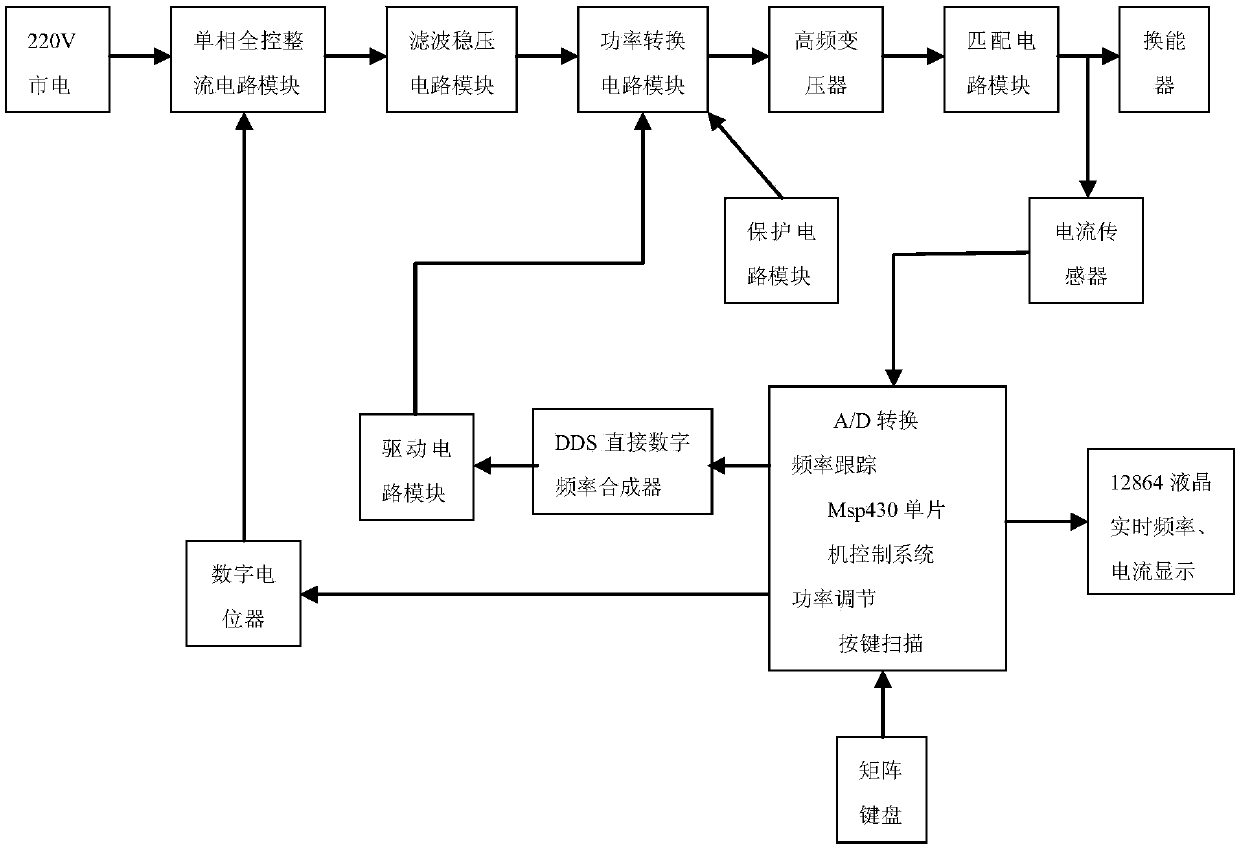

[0030] Such as figure 1 As shown, an ultrasonic power supply includes a single-phase full-control rectification circuit module, a filter voltage stabilization circuit module, a power conversion circuit module and a high-frequency transformer connected in sequence, and is characterized in that it also includes a matching circuit module with adjustable inductance, A voltage control module, and a transducer, a current sensor, a controller module, a DDS direct digital frequency synthesizer and a drive circuit module connected in sequence; the high-frequency transformer is connected to the The transducer, the drive circuit module is connected to the power conversion circuit module, and the controller module, voltage control module, and single-phase full-control rectification circuit module are connected in sequence.

[0031] In addition, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com