A kind of fermented milk that increases drinking physical examination and reduces hanging wall and preparation method thereof

A technology of fermented milk and starter, applied in the field of fermented milk, to achieve the effect of increasing drinking physical examination, avoiding water analysis, and reducing product hanging on the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

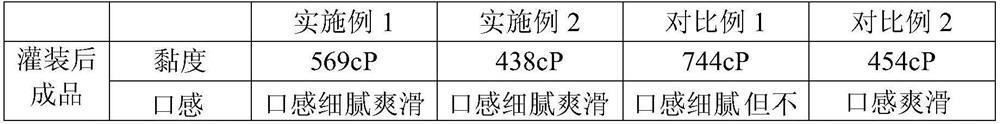

Examples

Embodiment 1

[0040] This embodiment provides a method for preparing fermented milk that increases drinking physical examination and reduces wall hanging, and fermented milk prepared by the method.

[0041] The raw materials of this fermented milk are (in 1000g): fresh milk or reduced milk 936g, white granulated sugar 60g, starch 3g, agar 0.6g and leavening agent: Streptococcus thermophilus 1×10 6 cfu / g, Lactobacillus bulgaricus 1×10 6 cfu / g, Lactococcus lactis 1×10 6 cfu / g.

[0042] The preparation method of this fermented milk specifically comprises the following steps:

[0043] (1) After heating fresh milk or reduced milk to 45-55°C, add white granulated sugar, starch and agar, and stir for 25-35 minutes to mix them evenly to obtain a mixed material liquid;

[0044] (2) After degassing the mixed material liquid, homogenize it at 60°C and 20 MPa to obtain a homogeneous mixed material liquid;

[0045] (3) Sterilize the homogenized mixed material at 110° C. for 10 minutes, and cool down...

Embodiment 2

[0053] This embodiment provides a method for preparing fermented milk that increases drinking physical examination and reduces wall hanging, and fermented milk prepared by the method.

[0054] The raw materials of this fermented milk are (in 1000g): fresh milk or reduced milk 936g, white granulated sugar 60g, starch 3g, agar 0.6g and leavening agent: Streptococcus thermophilus 1×10 6 cfu / g, Lactobacillus bulgaricus 1×10 6 cfu / g, Lactococcus lactis 1×10 6 cfu / g.

[0055] The preparation method of this fermented milk specifically comprises the following steps:

[0056] (1) After heating fresh milk or reduced milk to 45-55°C, add white granulated sugar, starch and agar, and stir for 25-35 minutes to mix them evenly to obtain a mixed material liquid;

[0057] (2) After degassing the mixed material liquid, homogenize it at 60°C and 20 MPa to obtain a homogeneous mixed material liquid;

[0058] (3) Sterilize the homogenized mixed material at 110° C. for 10 minutes, and cool down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com