Pod rotation hydraulic drive system

A drive system, hydraulic technology, applied in the direction of fluid pressure actuation devices, non-mechanical gear transmission devices, etc., can solve the problems of low efficiency and poor stability, and achieve the effect of avoiding energy loss, increasing stability and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

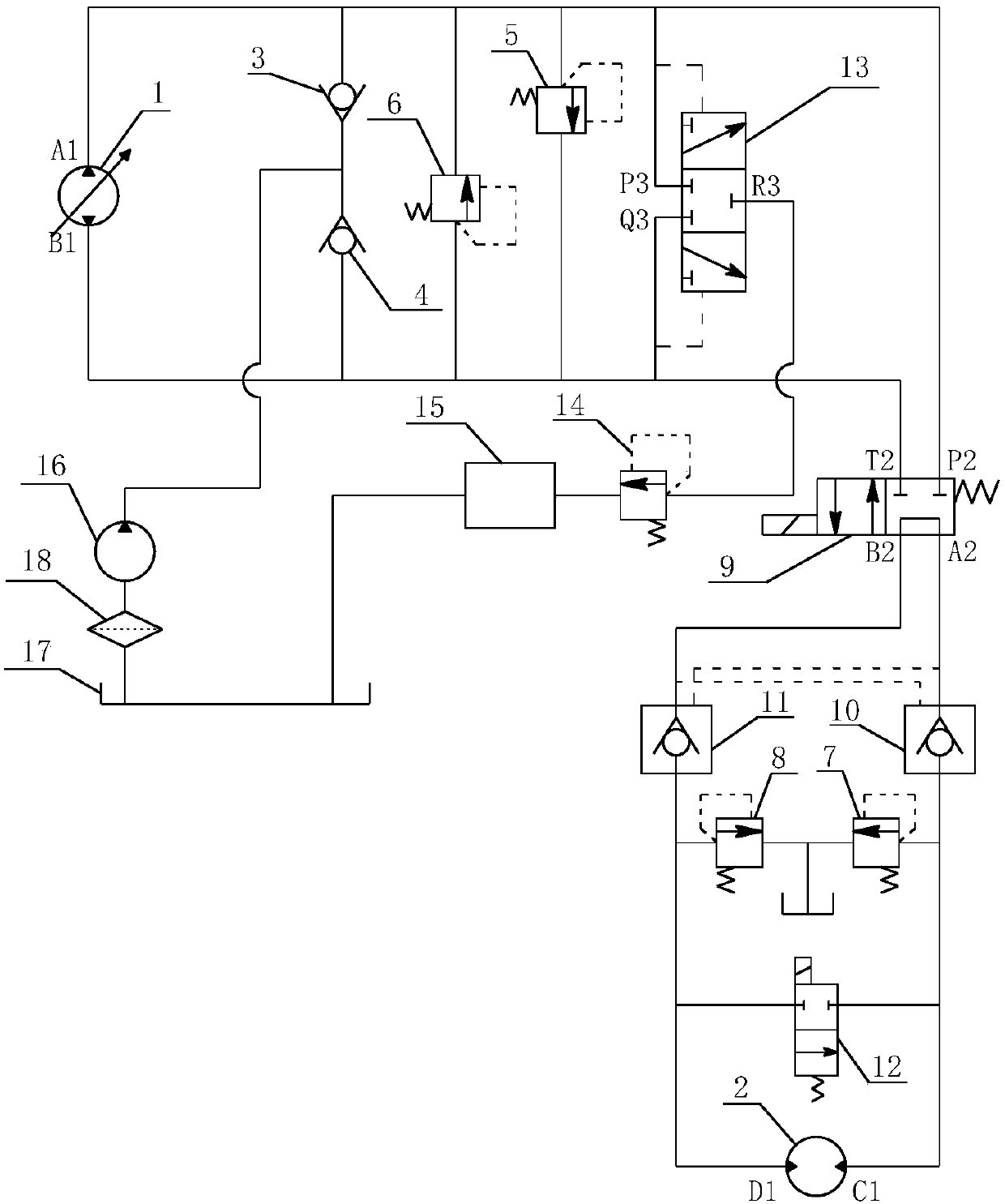

[0009] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0010] Such as figure 1 As shown, a pod rotation hydraulic drive system provided by the present invention is suitable for the use of pod rotation. The pod rotation hydraulic drive system includes a bidirectional variable pump 1, a hydraulic motor 2, a first one-way valve 3, a second one-way Directional valve 4, first relief valve 5, second relief valve 6, third relief valve 7, fourth relief valve 8, two-position four-way solenoid valve 9, first hydraulic control check valve 10, second relief valve Two hydraulically controlled one-way valves 11, two-position two-way solenoid valves 12, flushing valves 13, back pressure valves 14, coolers 15, charge pumps 16 and oil tanks 17.

[0011] The A1 port of the bidirectional variable pump 1 is connected to the P2 port of the two-position four-way solenoid valve 9, the B1 port of the two-way variable variable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com