High-efficiency digital transfer process for fabrics

A digital transfer printing, high-efficiency technology, applied in the printing process, transfer printing method, printing, etc., can solve the problem of ink not being strong enough, and achieve good printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

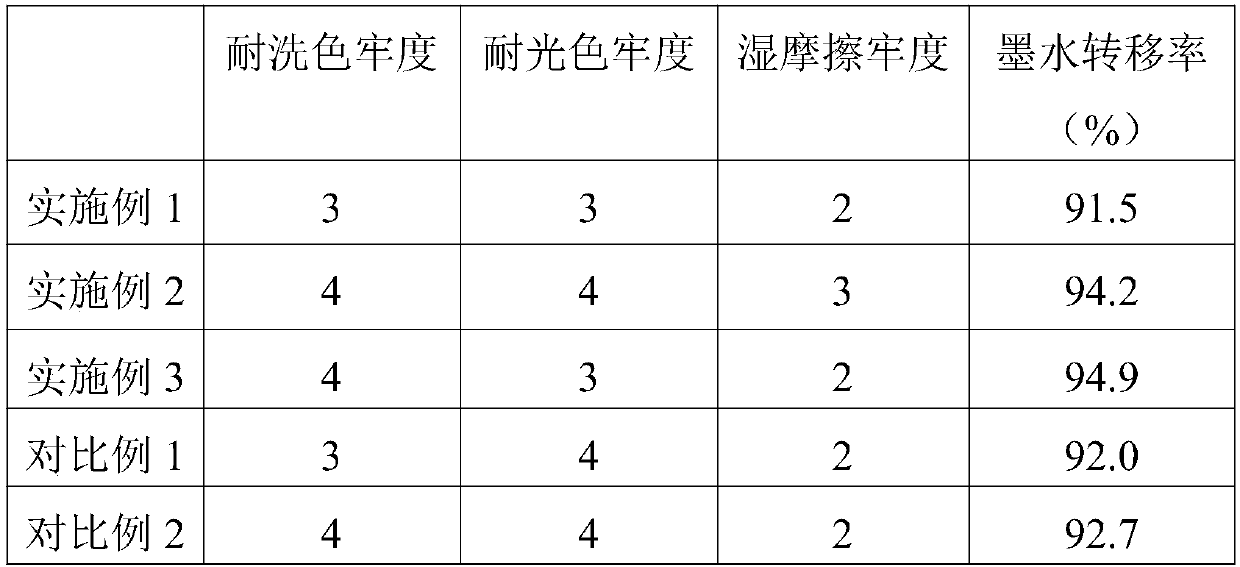

Embodiment 1

[0050] A high-efficiency digital transfer printing process for fabrics, comprising the steps of:

[0051] S1. Printing: Input the selected printing pattern into the TS5-1600AMF color inkjet printer (open the WASATCH software, open the required pattern in the software, and then set the size of the printing pattern and arrange it), spray the ink printed on transfer paper;

[0052] S2. Transfer printing: Lay the ink-jetted side of the transfer paper to the fabric, and use a heat press machine JC-7B to transfer for 15 seconds at a pressure of 10 tons / square meter and a temperature of 140°C. The ink on the transfer paper is transferred on the fabric;

[0053] S3. Steaming: Put the transferred fabric into a steamer and steam for 15 minutes at a steaming temperature of 105°C;

[0054] S4. Cooling: After naturally cooling to room temperature, tear off the cold transfer paper on the fabric and remove it to obtain a digitally printed fabric.

[0055] The preparation process of the in...

Embodiment 2

[0058] A high-efficiency digital transfer printing process for fabrics, comprising the steps of:

[0059] S1. Printing: Input the selected printing pattern into the TS5-1600AMF color inkjet printer (open the WASATCH software, open the required pattern in the software, and then set the size of the printing pattern and arrange it), spray the ink printed on transfer paper;

[0060] S2. Transfer printing: Lay the ink-jetted side of the transfer paper to the fabric, and use a heat press machine JC-7B to transfer for 15 seconds at a pressure of 10 tons / square meter and a temperature of 140°C. The ink on the transfer paper is transferred on the fabric;

[0061] S3. Steaming: Put the transferred fabric into a steamer and steam for 15 minutes at a steaming temperature of 105°C;

[0062] S4. Cooling: After naturally cooling to room temperature, tear off the cold transfer paper on the fabric and remove it to obtain a digitally printed fabric.

[0063] The preparation process of the in...

Embodiment 3

[0082] A high-efficiency digital transfer printing process for fabrics, comprising the steps of:

[0083] S1. Printing: Input the selected printing pattern into the TS5-1600AMF color inkjet printer (open the WASATCH software, open the required pattern in the software, and then set the size of the printing pattern and arrange it), spray the ink printed on transfer paper;

[0084] S2. Transfer printing: Lay the ink-jetted side of the transfer paper to the fabric, and use a heat press machine JC-7B to transfer for 15 seconds at a pressure of 10 tons / square meter and a temperature of 140°C. The ink on the transfer paper is transferred on the fabric;

[0085] S3. Steaming: Put the transferred fabric into a steamer and steam for 15 minutes at a steaming temperature of 105°C;

[0086] S4. Cooling: After naturally cooling to room temperature, tear off the cold transfer paper on the fabric and remove it to obtain a digitally printed fabric.

[0087] The preparation process of the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com