Electric control mechanical driving clip dry cell self switching power supply device

A technology of mechanical drive and power supply device, applied in terminal battery switching devices and other directions, can solve the problems of time-consuming and laborious, unstable power supply, affecting the working efficiency of power-consuming devices, etc., and achieve the effect of improving detection efficiency and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

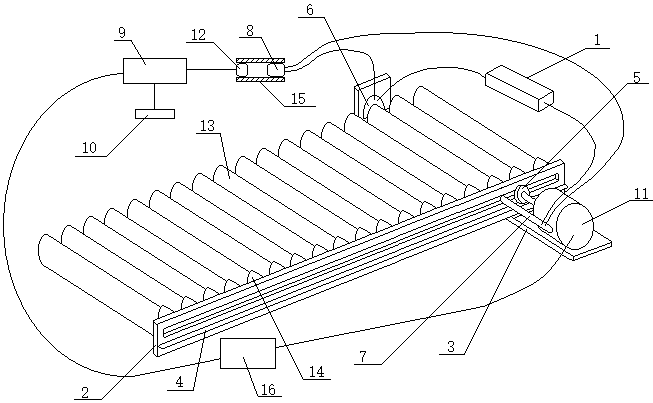

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

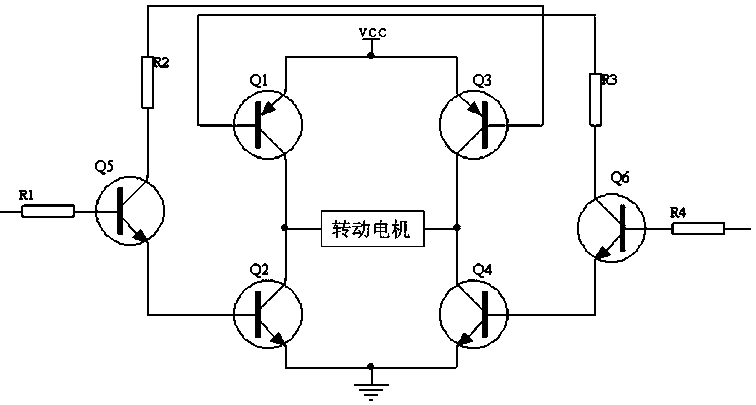

[0018] like figure 1 As shown, the present invention designs an electronically controlled mechanically driven clip-type dry battery self-switching power supply device, which uses a designated type of dry battery 13 to supply power to the electrical device 1; it includes a long strip 2 and a locking plate 3 with an L-shaped structure on the side , rack 4, gear 5, electrode sheet 6, conductive rod 7, strip conductive sheet, light source 8, rotating motor 11, at least two sleeves 14 and control module 9, and the independent power supply that is connected with control module 9 respectively Power supply 10, photosensitive sensor 12, motor drive circuit 16; Rotating motor 11 is connected with control module 9 through motor drive circuit 16; Wherein, independent power supply 10 supplies power for photosensitive sensor 12 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com