Static loading device special for haze removal system nozzle

A loading device and electrostatic technology, applied in the direction of spray discharge device, electrostatic spray device, spray device, etc., can solve the problems of fixed and non-rotating nozzles, achieve reliable power supply, and improve the effect of haze removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

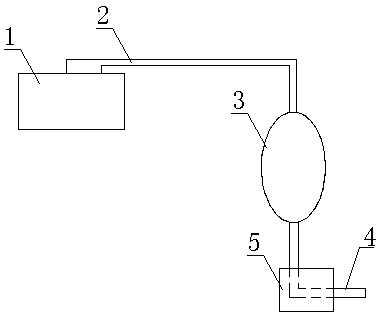

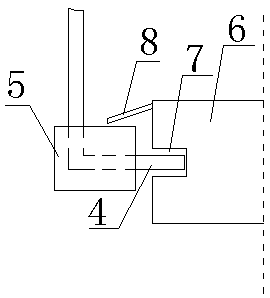

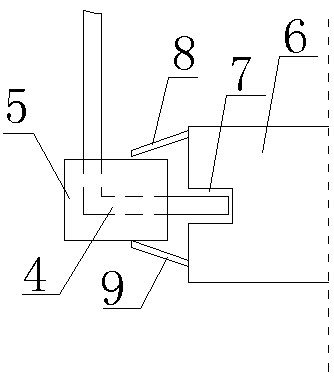

[0018] figure 1 Shown is a special electrostatic loading device for the nozzle of the haze elimination system, including the electrostatic loading ring 1, the support link 2, the limit fixing ring 3, the brush 4, the brush sheath 5 and the power supply connector 6; the electrostatic loading ring 1 It is fixed on one end of the supporting link 2, and the limit fixing ring 3 is fixed on the other end of the supporting link 2; the limit fixing ring 3 is used to be set on the water inlet pipe section of the self-rotating nozzle; the electric brush 4 is fixed on the limit fixing ring 3, and the brush 4 is in contact with the brush on the power supply connector 6 to communicate with the circuit; the brush sheath 5 is set outside the brush 4.

[0019] The support connecting rod 2 is fixed on the pipe section where the spray head is located through the limit fixing ring 3. At the same time, the electric brush 4 fixed under the limit fixing ring 3 is in conflict with the electric termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com