Pre-drilling device for internal high pressure forming pipe fittings

A technology of internal high pressure forming and pre-drilling, which is applied in boring/drilling, drilling/drilling equipment, metal processing, etc. It can solve problems such as reducing production efficiency, affecting the quality of finished pipe fittings, and center hole eccentricity. Guarantee the effect that quality and production efficiency will not be affected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

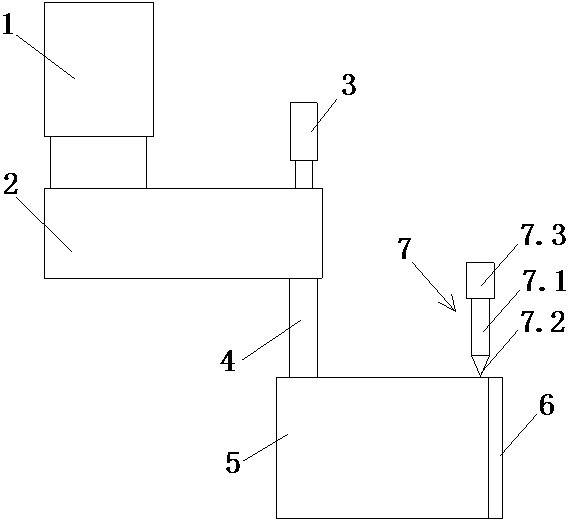

[0013] The invention relates to a pre-drilling device for internal high-pressure forming pipe fittings. The pre-drilling device is arranged between a heating furnace 1 and a drilling station. The moving platform 2 is set at an inclination so that the pipe fittings can roll to the end of the moving platform 2, and the scale formed on the heated surface of the pipe fittings can be rolled off when rolling. One side of the end of the moving platform 2 is provided with a pusher cylinder 3, and the pusher cylinder 3. Push the last pipe fitting on the sieve moving platform 2 onto the feeding rail 4, and the feeding rail 4 transports the pipe fittings to the pre-drilling platform 5. The pre-drilling platform 5 is also inclined, and the pre-drilling platform 5 A baffle plate 6 is arranged at the end, and a pre-drilling device 7 is fixed on one side of the baffle plate 6. The pre-drilling device 7 includes a drill rod 7.1, and the two ends of the drill rod 7.1 are respectively connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com