Concrete stirring machine

A technology for concrete mixers and mixing drums, applied in mixing plants, cement mixing devices, clay preparation devices, etc., can solve the problems of inaccurate mixing time control, uneven mixing of raw materials, and a large number of manpower feeding, so as to improve the quality of finished products and save The effect of manpower, convenient feeding and water delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

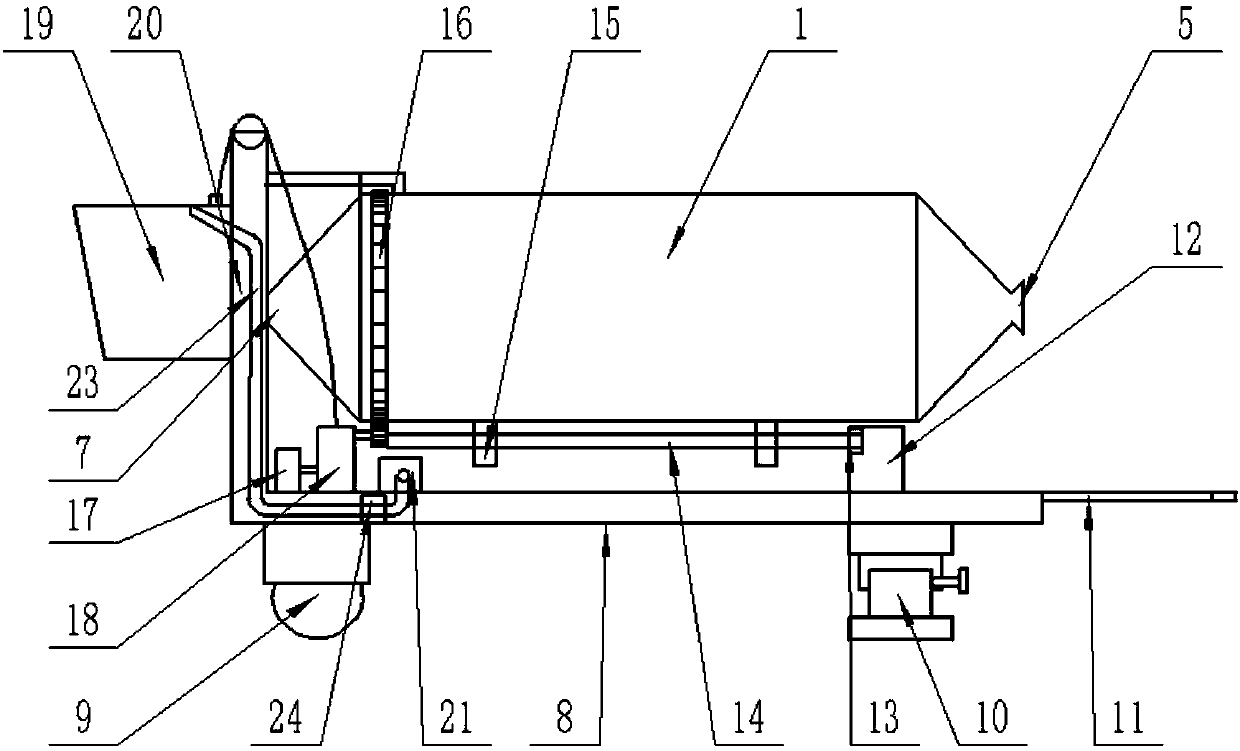

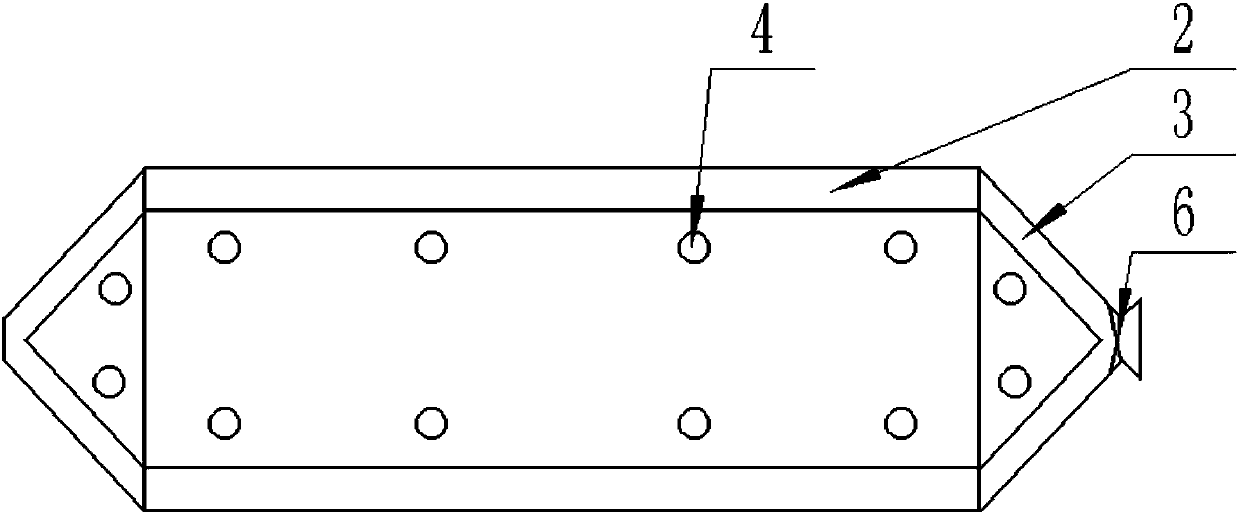

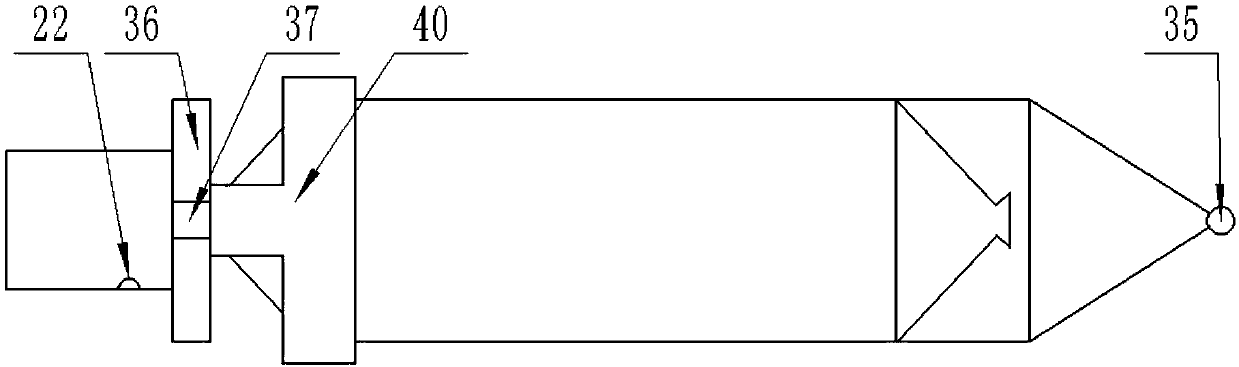

[0022] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6 As shown, a concrete mixer includes a mixing drum 1, the shape of the mixing drum 1 is biconical, and the mixing drum 1 is provided with a side liner 2 and an arc-shaped liner 3, and the side liner 2 and the The arc-shaped liner 3 is firmly connected with the inner wall of the mixing drum 1 by several screws 4. One end of the mixing drum 1 is provided with a discharge port 5, and a pair of semicircular blades 6 arranged in a high and low cross shape are provided at the discharge port 5. The opposite end of the mixing drum 1 to the discharge port 5 is provided with a feed inlet 7, a chassis 8 is provided below the mixing drum 1, and a pair of walking wheels 9 and a pair of supporting legs 10 are provided below the chassis 8, so that Two drawbars 11 are arranged on the chassis 8 and on both sides below the outlet 5, and two pairs of support blocks 12 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com