A high-efficiency recycling production line for cutting waste

A technology for cutting waste and production lines, applied in ceramic molding machines, chemical instruments and methods, clay preparation devices, etc., can solve problems such as affecting product quality, and achieve the effect of improving the work of pouring concrete, saving resources, and not easy to change the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

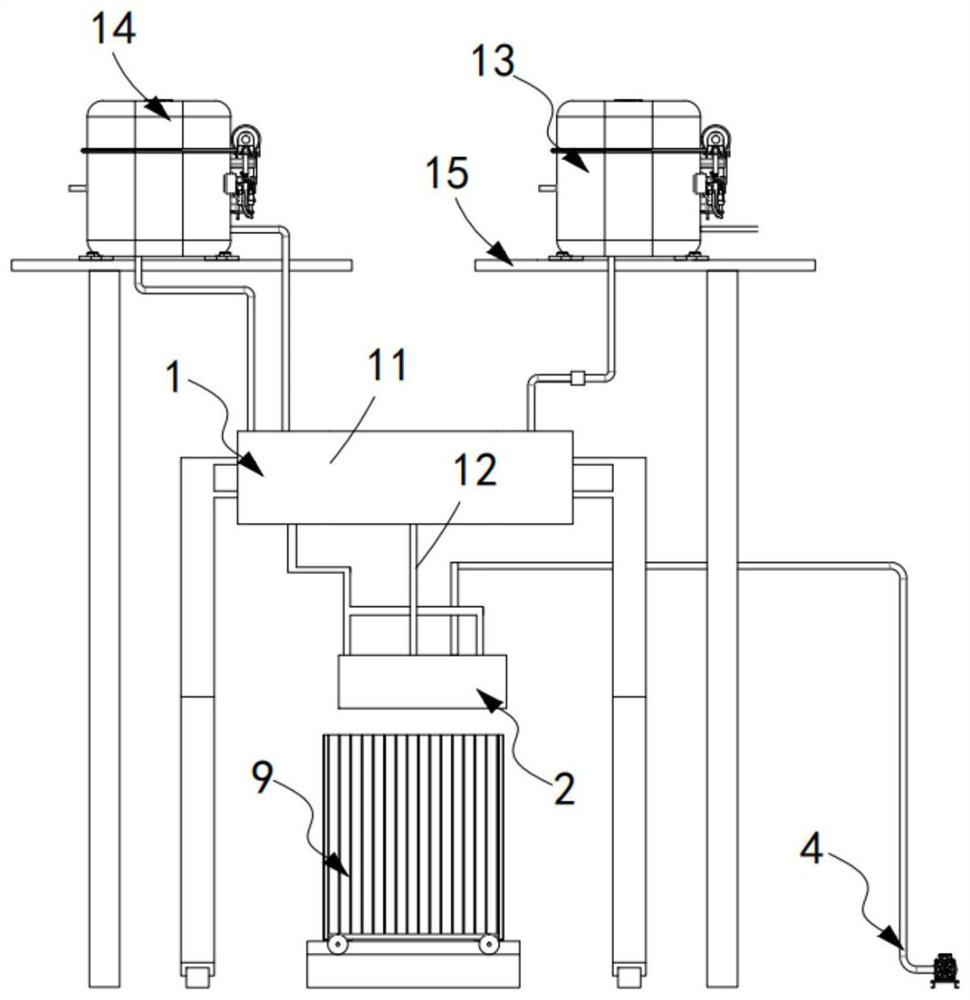

[0063] Such as figure 1 As shown, a production line for efficient recycling of cutting waste, including:

[0064] A material preparation mechanism 1, which includes a material storage bin 11, a feeding assembly 12 arranged at the output end of the storage bin 11, and a batching assembly 13 arranged above the storage bin 11;

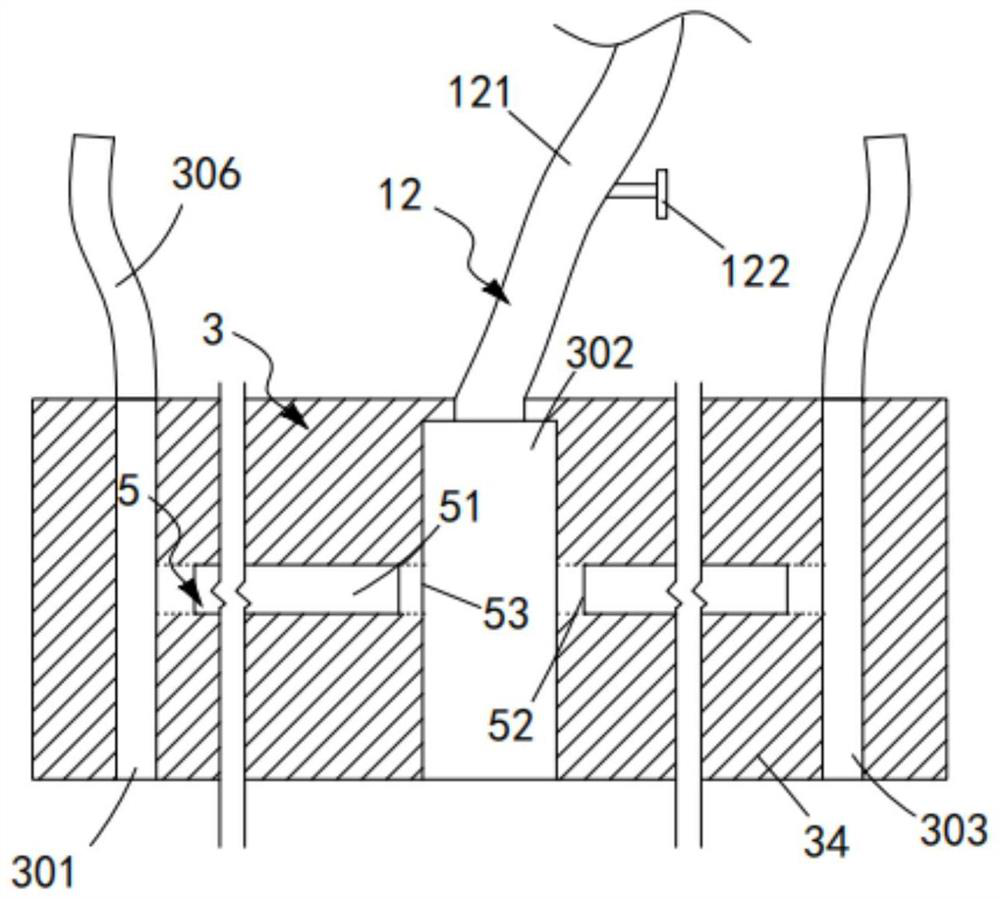

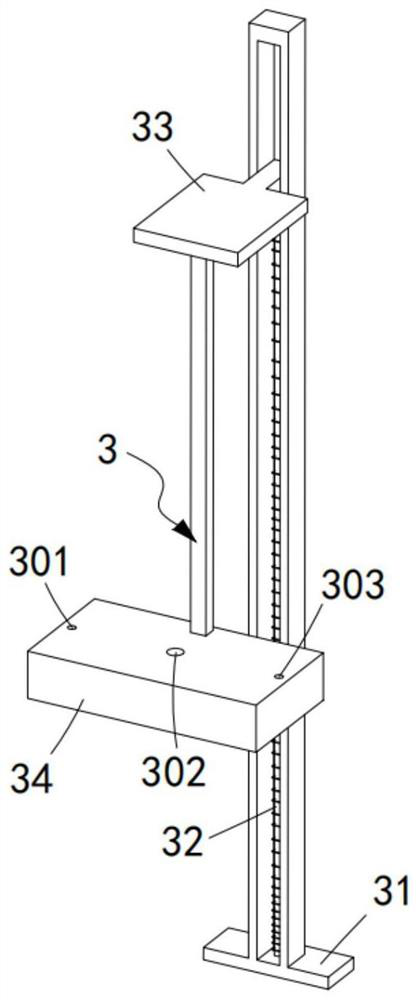

[0065] The unloading mechanism 2, the unloading mechanism 2 includes the lifting assembly 3 that is communicated with the feeding assembly 12 and is slidably arranged in the vertical direction, and is used to drive the lifting assembly 3 to move up and down in the vertical direction and intermittently start The driving assembly 4, the feeding assembly 5 arranged in the lifting assembly 3 and the exhaust assembly 6 arranged in the lifting assembly 3, the feeding assembly 5 and the exhaust assembly 6 pass through the switching assembly 7 Perform alternate work, the switching assembly 7 and the exhaust assembly 6 are set in linkage and synchronous transmiss...

Embodiment 2

[0106] Such as Figure 5 to Figure 7 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0107] further, such as Figure 5 to Figure 7 As shown, the exhaust assembly 6 includes a driving member 61 installed in the sealing plate 34 and installed in the installation groove 304 along the width direction of the sealing plate 34, and the exhaust gas that is driven by the driving member 61 62, a sealing member 63 arranged on the exhaust member 62, and a ventilation member 64 for discharging the gas discharged when the exhaust member 62 moves in the same direction.

[0108] In this embodiment, by setting the driver 61 to drive the exhaust piece 62, on the one hand, it can support and guide the exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com