Timber drying and transporting vessel

A technology for drying wood and transporting ships. It is used in transportation and packaging, ship hulls, ship parts, etc. It can solve problems such as taking up inventory, unable to dry wood in time, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

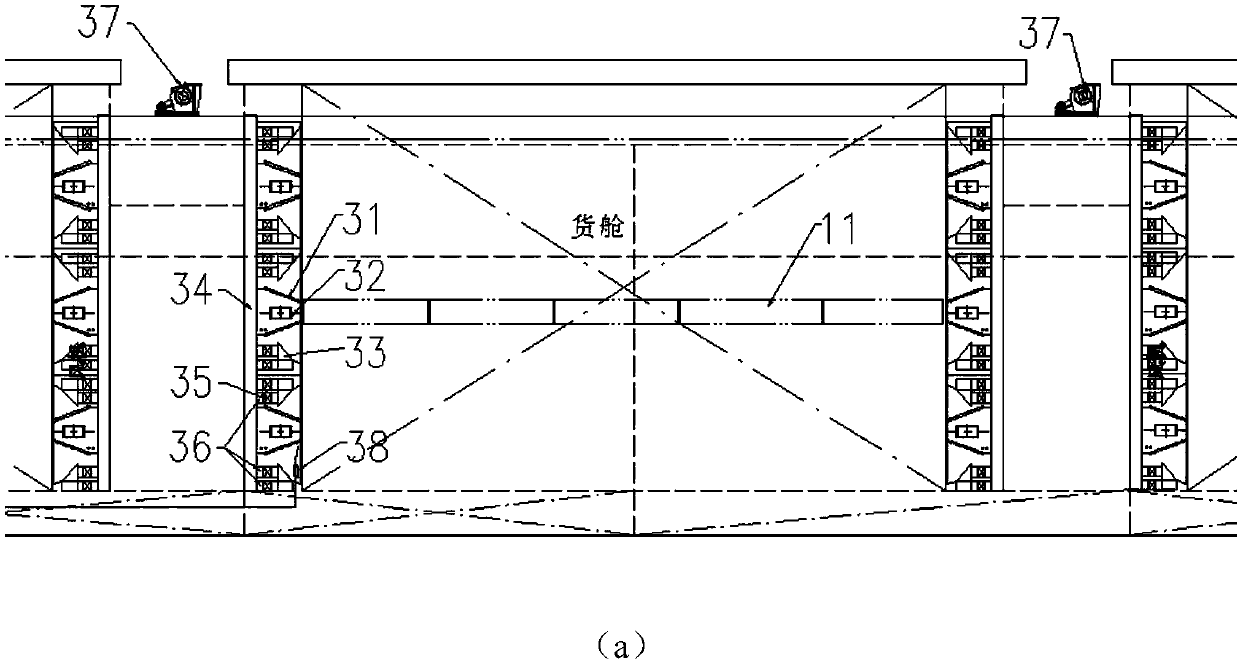

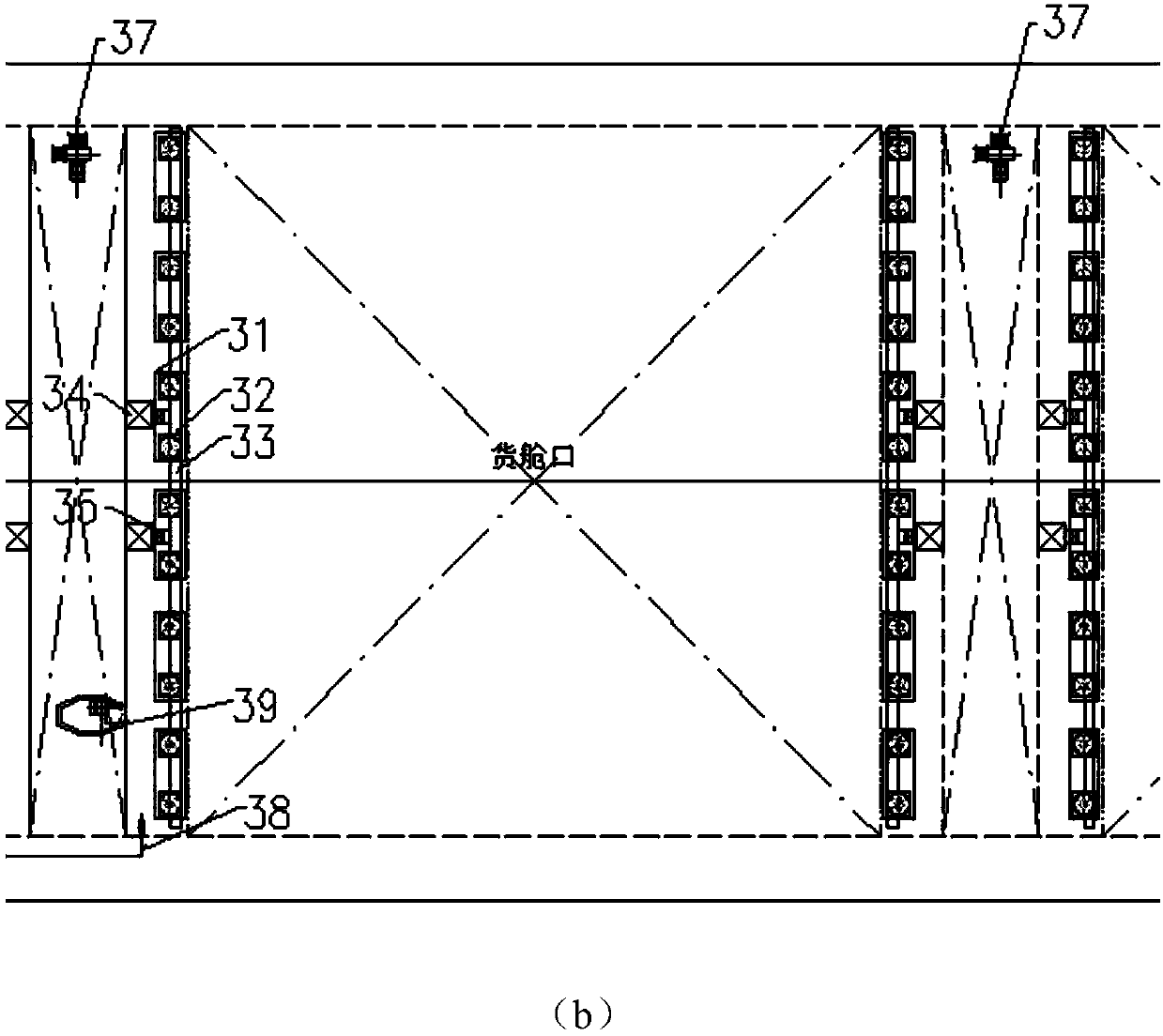

[0020] The timber drying ship involved in the invention will be described in detail below with reference to the accompanying drawings.

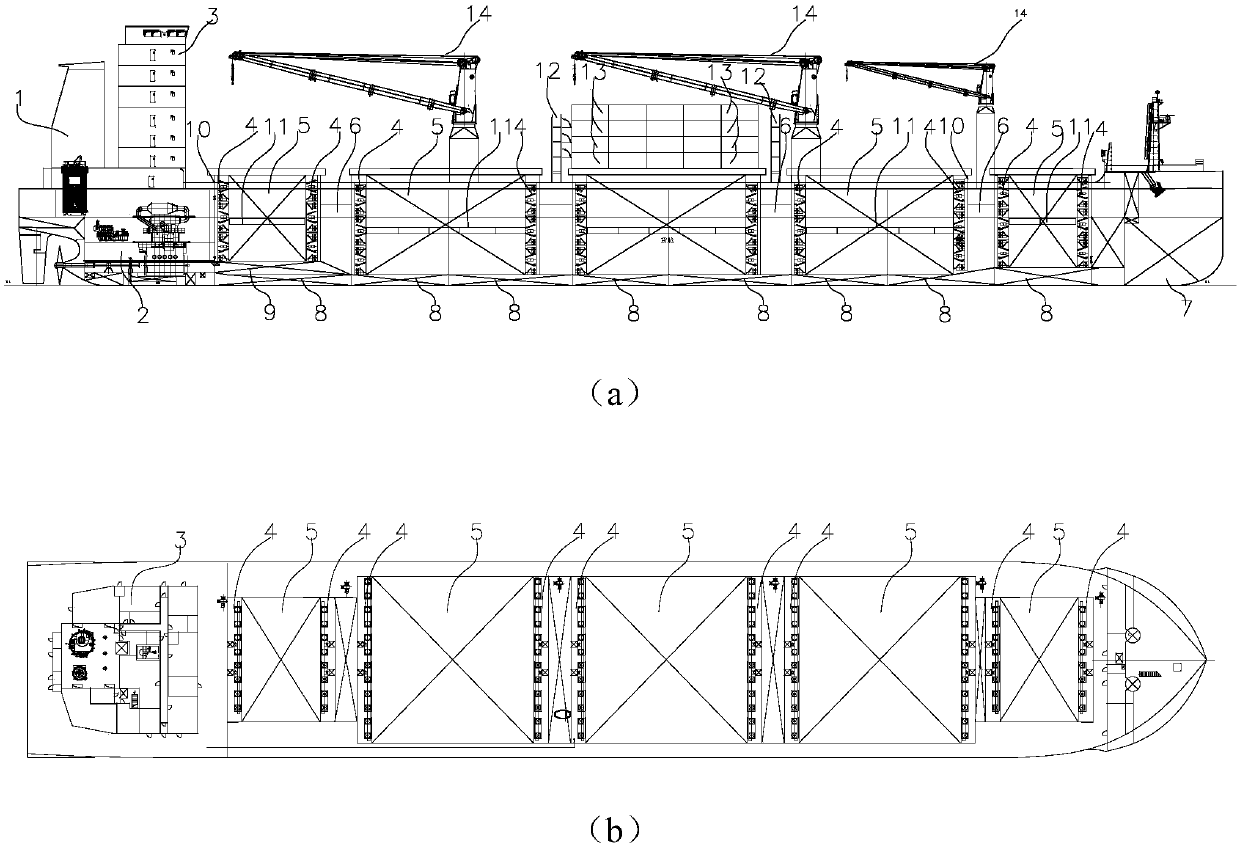

[0021] figure 1 It is a schematic diagram of the general arrangement of the timber drying transport ship. This embodiment exemplifies a wood drying transport ship. The shape of the ship is based on a conventional multi-purpose ship, with a total of 4 to 5 large cabins, a length of 170 to 200 meters, a molded depth of 8 to 12 meters, a molded width of 26 to 31 meters, and a load capacity of 26,000 to 40,000 tons.

[0022] From the stern to the bow, there are engine room canopy 1, engine room 2, living building 3, cargo hold area, and fore peak tank 7. The cargo hold area includes cargo hold 5 , fuel oil tank 6 , ballast tank 8 , empty space 9 and hatch coaming 10 .

[0023] The shape of the cargo hold is a cuboid shape, which is convenient for stacking materials, especially the cargo hold at the bow and stern is also designed in a cuboid sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com