Subway line track bed sleeper nylon sleeve failure treatment construction method

A nylon casing and construction method technology, applied in the field of engineering technology science, can solve the problems of large investment, time-consuming and laborious, etc., and achieve the effects of saving construction time, ensuring accuracy, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

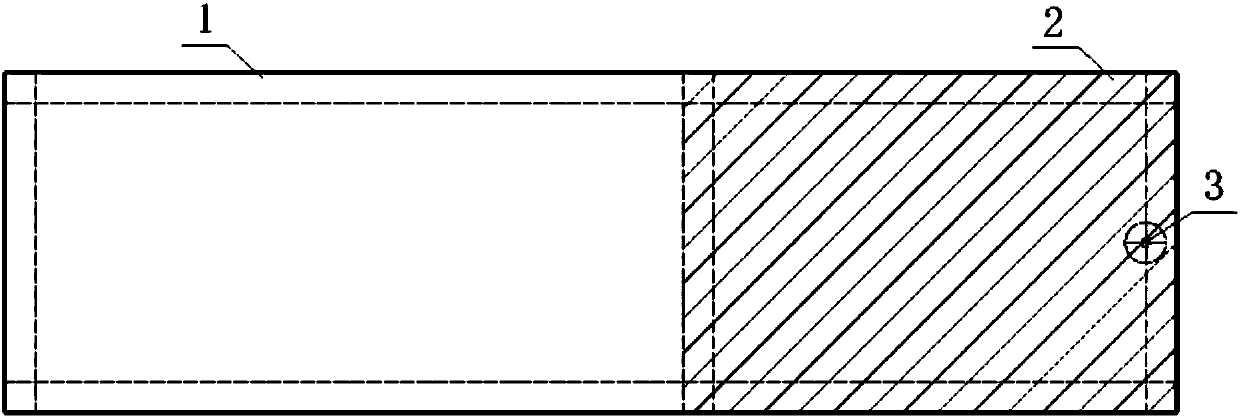

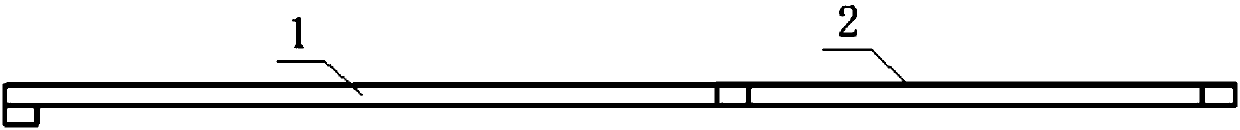

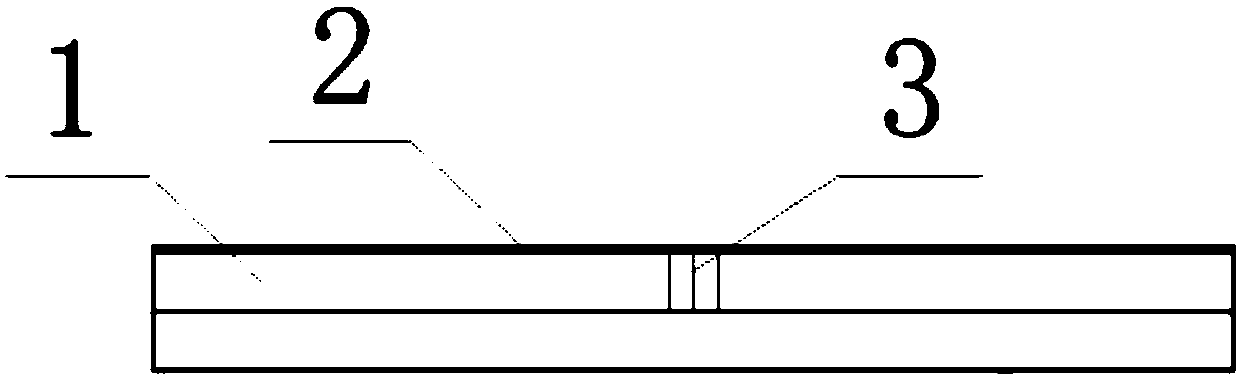

[0038] see Figure 1-3 , the operation platform for failure treatment of pre-embedded nylon sleeves in track bed sleepers of subway operation lines is mainly composed of operation platform frame (1), platform iron plate (2), and horizontal adjustment air bubbles (3).

[0039] see Figure 1-3 , the frame structure of the operating platform is welded by two 1900mm long and three 550mm long channel steels 50×37×4.5mm, one 550mm long channel steel is set at the bottom of the operating platform frame at one end, and a 800mm × The 550mm×2.5mm iron plate is welded to the operating platform, and a horizontal adjustment bubble is drilled in the middle of the channel steel at one end of the iron plate frame and installed and fixed firmly after being tested.

[0040] see Figure 4 , Rail track bed sleeper nylon casing failure treatment for subway operation line fixed operating platform fixture (4), welded by one 300mm long and 2 120mm long channel steel 50×37×4.5mm, the upper part is 1...

Embodiment 2

[0046] see Figure 9 24 hours after the new nylon sleeve (13) is anchored, its coagulation strength meets the requirements. Use a hoist to lift the rail and install the fasteners. First install the rubber backing plate and the iron backing plate under the plate. After the bolts are tightened, place the rubber pad under the rail. When placing it, the rubber pad under the rail falls into the groove of the iron backing plate and gets stuck. Gauge pads, fastener clips, and T-bolts. Check that the track gauge, direction, height, triangular pit and other track state geometric dimensions and fastener bolt torque meet the specification requirements, so that the line state meets the requirements for operation and opening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com