Continuous variable valve mechanism

A valve train, variable technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as reducing structural strength and reliability, improving operating noise level, and the valve cannot be fully closed, reducing processing costs, The effect of prolonging the service life and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

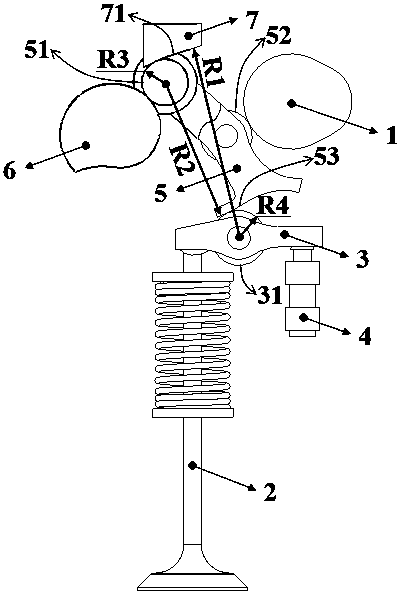

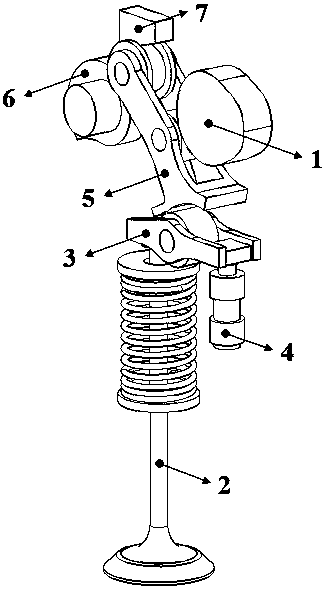

[0011] The invention relates to a continuously variable valve mechanism. figure 1 and figure 2 are its front view and side view, respectively. It includes a cam 1, a valve assembly 2, a rocker arm 3, and a rocker arm fulcrum 4, and is characterized in that it also includes an adjustable rocker arm 5, an eccentric wheel 6, a track 7 and a rocker arm spring. An output roller 31 with a radius R4 is arranged in the middle of the rocker arm 3 , and both ends of the rocker arm 3 are in contact with the valve assembly 2 and the rocker arm fulcrum 4 respectively. The adjustable rocker arm 5 is provided with an adjustable roller 51 , an input roller 52 and an output curved surface 53 , and the radius of the adjustable roller 51 is R3. The track 7 is provided with an adjusting curved surface 71 . The adjustable roller 51 is in contact with the eccentric wheel 6 and the adjusting curved surface 71 at the same time, the output curved surface 53 is in contact with the output roller 31 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com