Front-end air inlet device for treating lampblack

An air intake device and oil fume treatment technology, which is applied in the direction of oil fume removal, application, household stove, etc., can solve problems such as loud noise, achieve the effect of simple and compact structure, improve smoking efficiency, and suppress vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

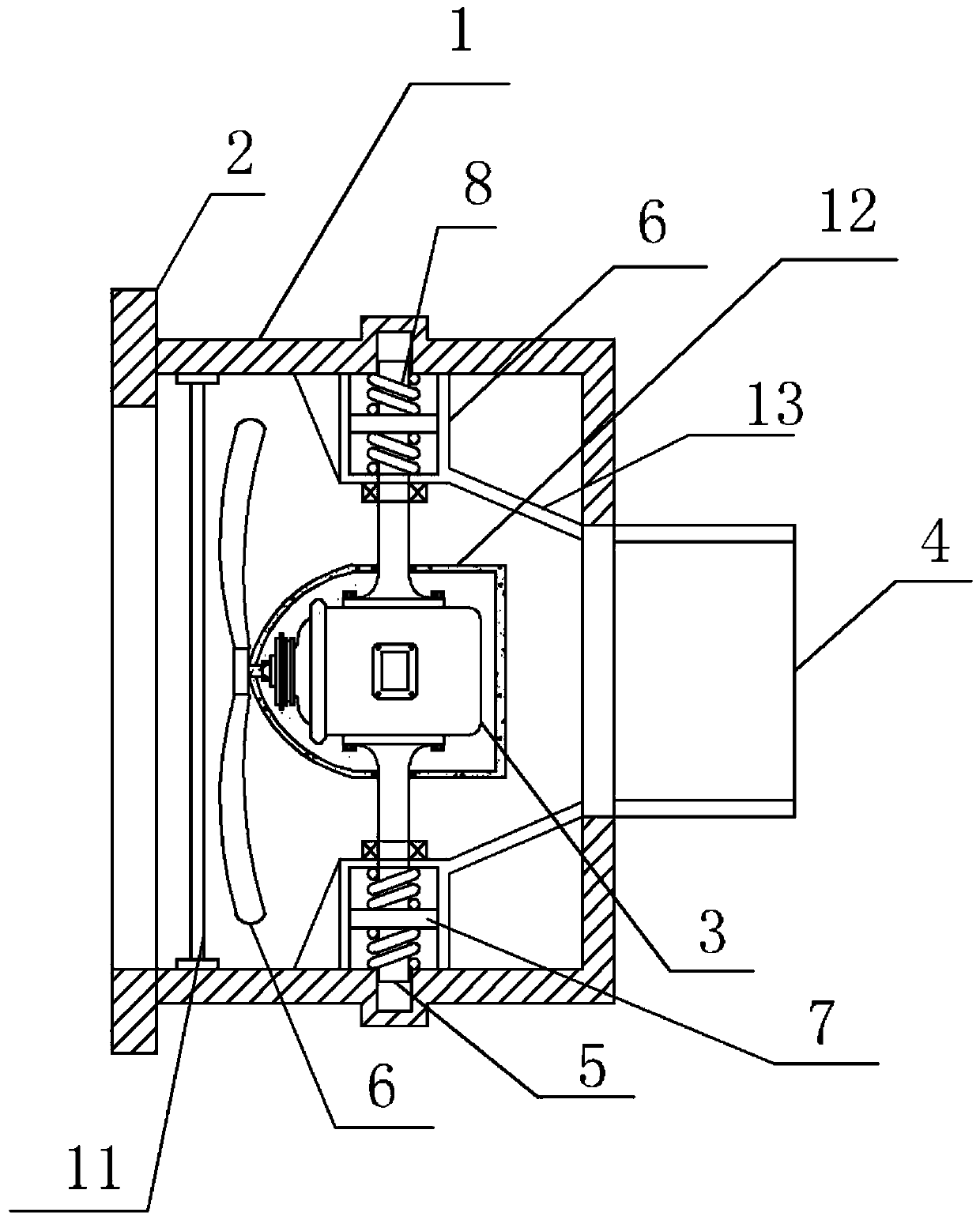

[0019] A front-end air intake device for oil fume treatment in this embodiment, such as figure 1 As shown, it includes a housing 1 with an opening A on one side and an air intake cover 2 arranged at the opening A of the housing 1. The housing 1 is provided with a fan 3 facing the opening A. The housing 1 An exhaust port 4 is provided on the side away from the opening A; both sides of the fan 3 are movably connected with the housing 1 through a damping device arranged on the inner wall of the housing 1; the damping device is fixedly connected with the fan 3 The connecting rod 5 is composed of a shock absorbing cylinder 6 fixed on the inner wall of the housing 1. The end of the connecting rod 5 away from the fan 3 is inserted into the shock absorbing cylinder 6 and reciprocates along the axial direction in the shock absorbing cylinder 6; the connecting rod 5 is inserted into the One end is provided with a circular baffle 7 perpendicular to the connecting rod 5, the curved side w...

Embodiment 3

[0022] This embodiment is further defined on the basis of the above embodiments, the casing 1 is provided with a metal mesh filter layer 11 for filtering between the opening A and the fan 3 . The outside of the fan 3 is provided with an oil-proof shell 12 that completely wraps the fan 3 . One side of the opening B is provided with a conical shroud 13 . The shell 1 is provided with a sound-insulating sponge layer on the outside. Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com