Heat Storage Module Using Phase Change Material and Manufacturing Method Thereof

A latent heat storage and heat storage technology, applied in heat storage equipment, heat exchanger types, indirect heat exchangers, etc. The effect of heat release efficiency, increasing heat storage density, and reducing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] First, before describing the present invention in detail, if it is judged that the detailed description of known technologies or configurations related to the present invention will make the gist of the present invention unclear, the detailed description will be omitted.

[0065] In addition, the terms described later are terms defined in consideration of the functions in the present invention, which vary depending on the intentions or practices of users and operators. It is defined by the entire content of this specification described in "Heat Storage Module and Manufacturing Method Thereof".

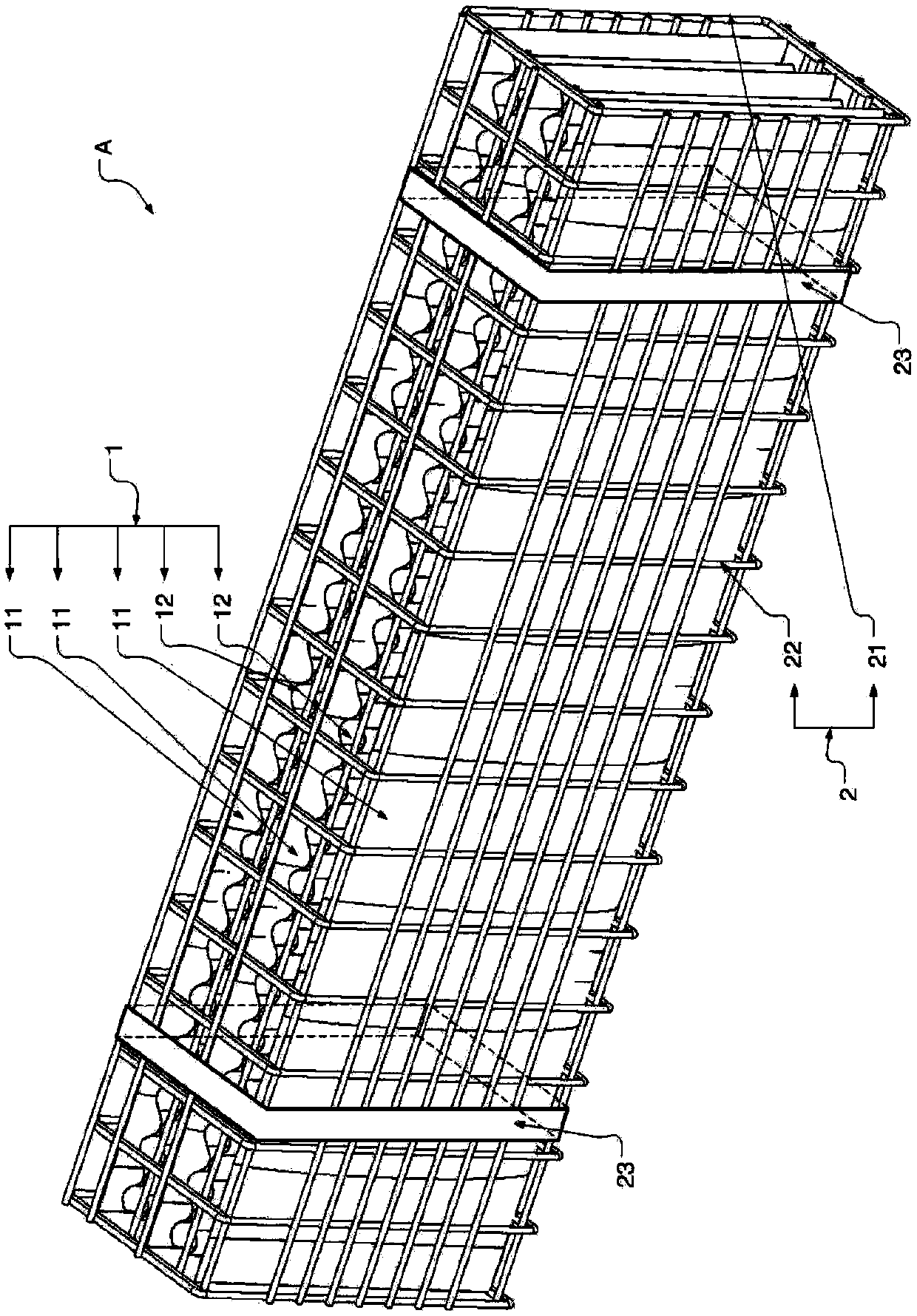

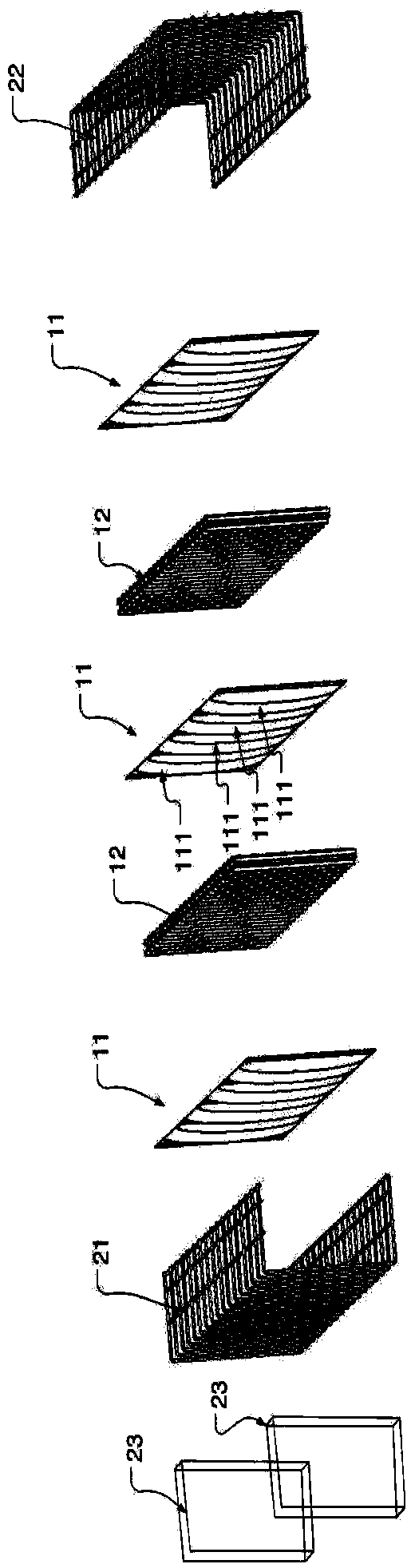

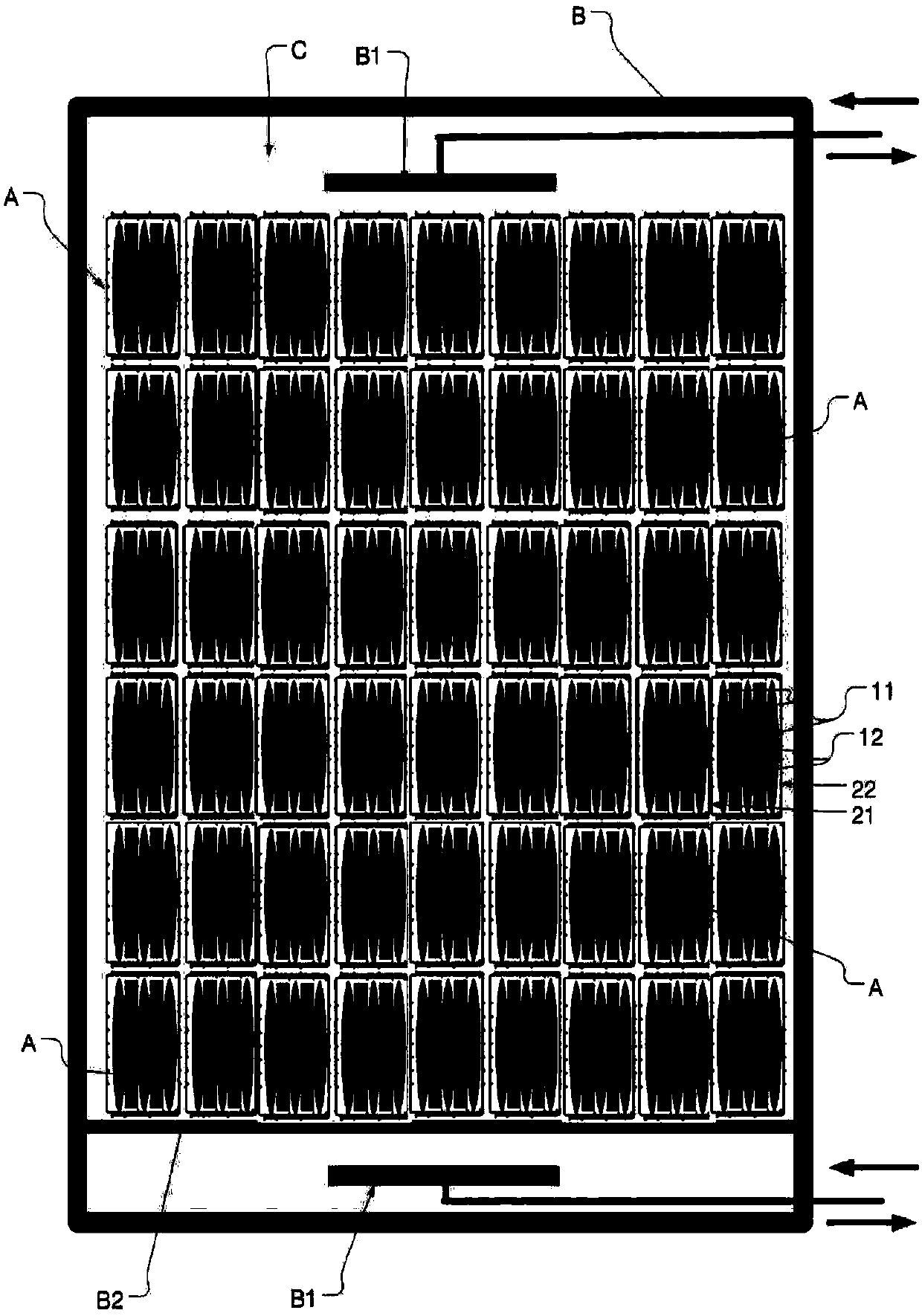

[0066] Next, preferred embodiments of the "thermal storage module using a latent heat storage material for cooling and heating and its manufacturing method" of the present invention will be described in detail.

[0067] The following examples are merely illustrative for explaining the present invention, and the scope of the present invention is not limited thereto.

[0068] f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap