Method and device for evaluating liquid permeability of blast furnace charge column

An evaluation method and evaluation device technology, which can be applied in the fields of measurement device, permeability/surface area analysis, suspension and porous material analysis, etc., which can solve the problems such as the failure to intuitively give the change law of the liquid permeability of the material column and the complicated operation. , to achieve the effect of intuitive and reliable evaluation results, simple operation and solving evaluation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

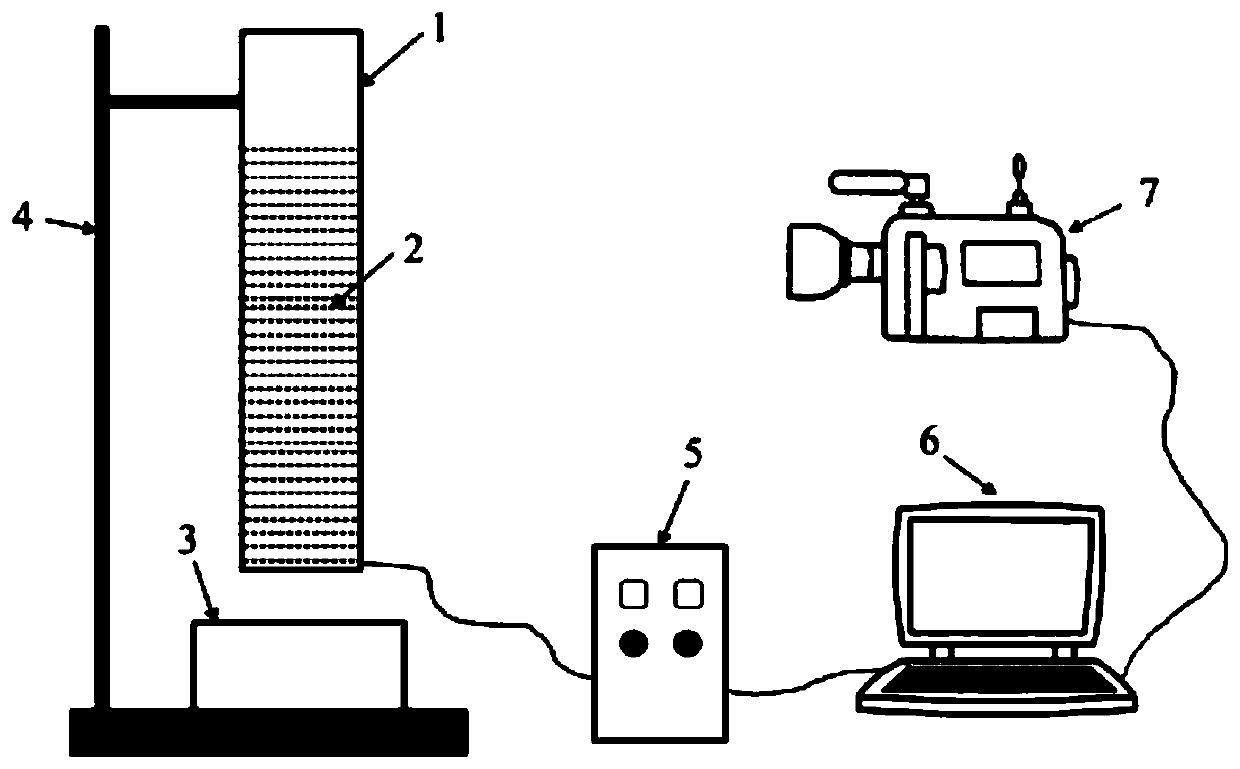

[0039] The preparation of the material column sample is obtained by simulating the temperature of the lower material column of the blast furnace shaft and the pressure of the upper material column. After placing coke with a grain size of 20-25mm in the customized quartz crucible 1, the height of the coke material column is controlled at 200-250mm, and a 5kg superalloy column is loaded above the coke material surface to simulate the load of the coke material column on the upper material column pressure. Then put the sample crucible in a 1300°C high-temperature vacuum carbonization furnace for carbonization for 2 hours, and take out the crucible after the high-temperature vacuum carbonization furnace cools down to room temperature.

[0040] In the preparation of the material column sample of the present invention, double samples are prepared for experiments, so as to avoid artificial errors.

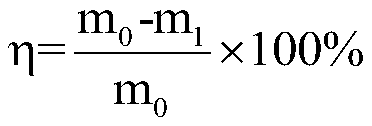

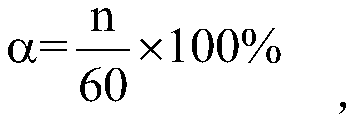

[0041] When using the drop test device to carry out the resin penetration material colu...

Embodiment 1

[0056] (1) Prepare 20-25mm coke particles, put them into the quartz crucible 1, and put them into a height of 200mm; then place the superalloy column on the surface of the coke column;

[0057] (2) Then place the quartz crucible 1 in a high-temperature vacuum carbonization furnace. The high-temperature vacuum carbonization furnace rises from room temperature to 1300° C. at a heating rate of 10° C. / min, and then heats it for 2 hours, stops heating, and takes out the sample after naturally cooling to room temperature;

[0058] (3) The heating wire 2 is spirally wound on the outer wall of the quartz crucible 1, the operating position of the quartz crucible 1 is fixed with a support 4, and the glass cup 3 is placed under the quartz crucible 1 to collect the resin dripped in the experiment;

[0059] (4) Open heating controller 5, video camera 7, set the temperature of heating wire 2 and the parameter of video camera 7 by computer 6;

[0060] (5) Pour the pre-prepared resin into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com