Positive pressure type explosion-proof control cabinet

A technology of control cabinets and control boxes, which is applied in the direction of sealed enclosures, etc., and can solve problems such as small range of dangerous places, unsuitable equipment for sparks or arcs, and prone to flash accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

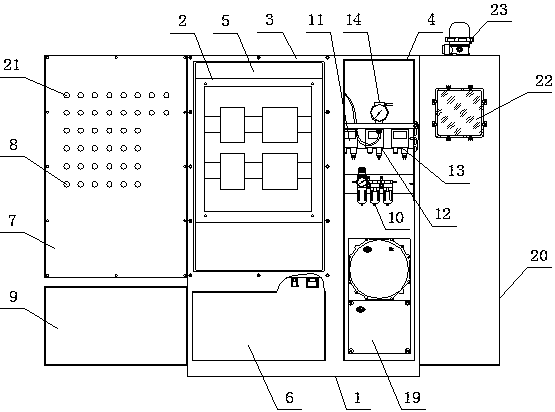

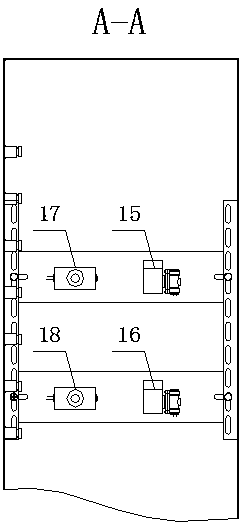

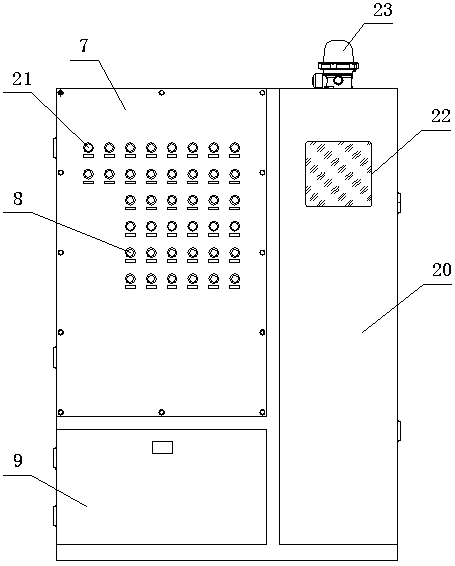

[0013] Such as figure 1 As shown, the positive pressure explosion-proof control cabinet of the present invention is composed of a cabinet body 1, a main cavity element assembly 2, an explosion-proof solenoid valve, a throttle valve and a pressure switch. The cabinet body 1 is a closed structure, and the The top of the cabinet 1 is provided with an alarm 23. The cabinet 1 is composed of the main cabinet 3 and the auxiliary cabinet 4. In the main cabinet 3, the upper part is the electrical cavity 5, the lower part is the wiring cavity 6, and the electrical cavity 5 Component assembly 2 is arranged inside, electrical chamber door 7 is provided on electrical chamber 5, indicator light group 8 and button group 21 are provided on electrical chamber door 7, wiring chamber door 9 is provided on wiring chamber 6, and auxiliary cabinet body 4 is provided with auxiliary box body cabinet door 20, and described auxiliary box body cabinet door 20 is provided with glass window 22, and the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com