Carbon fiber heating fur clothes

A technology of carbon fiber heating and carbon fiber, which is applied in the direction of protective clothing, special outerwear, clothing, etc., can solve the problems of leather clothing not wear-resistant, low heat transfer efficiency, and easy to crack, so as to improve the firmness and wear resistance, and Good tensile strength and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following is the specific implementation of the present invention and further description of the technical solution of the present invention in conjunction with the accompanying drawings.

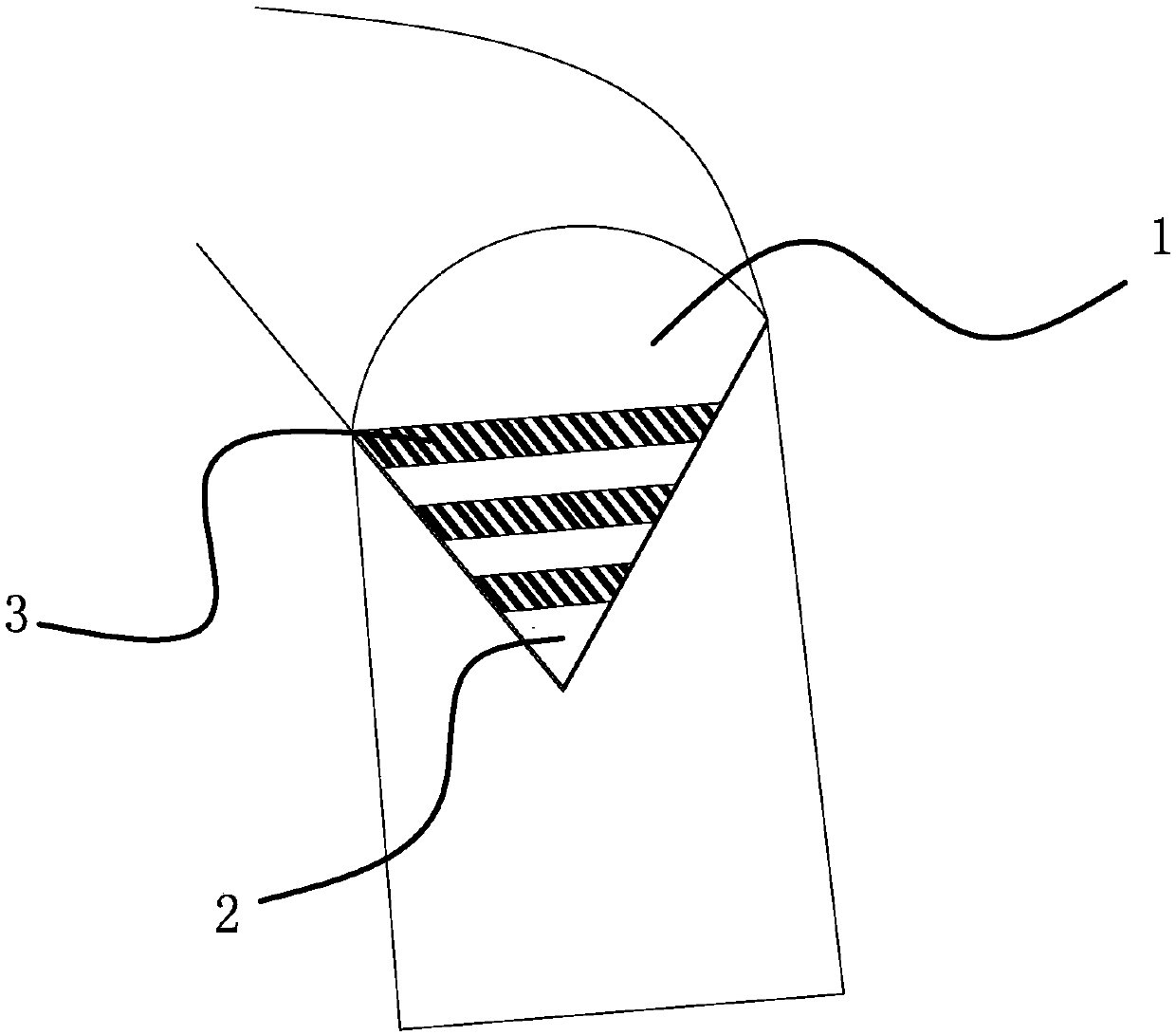

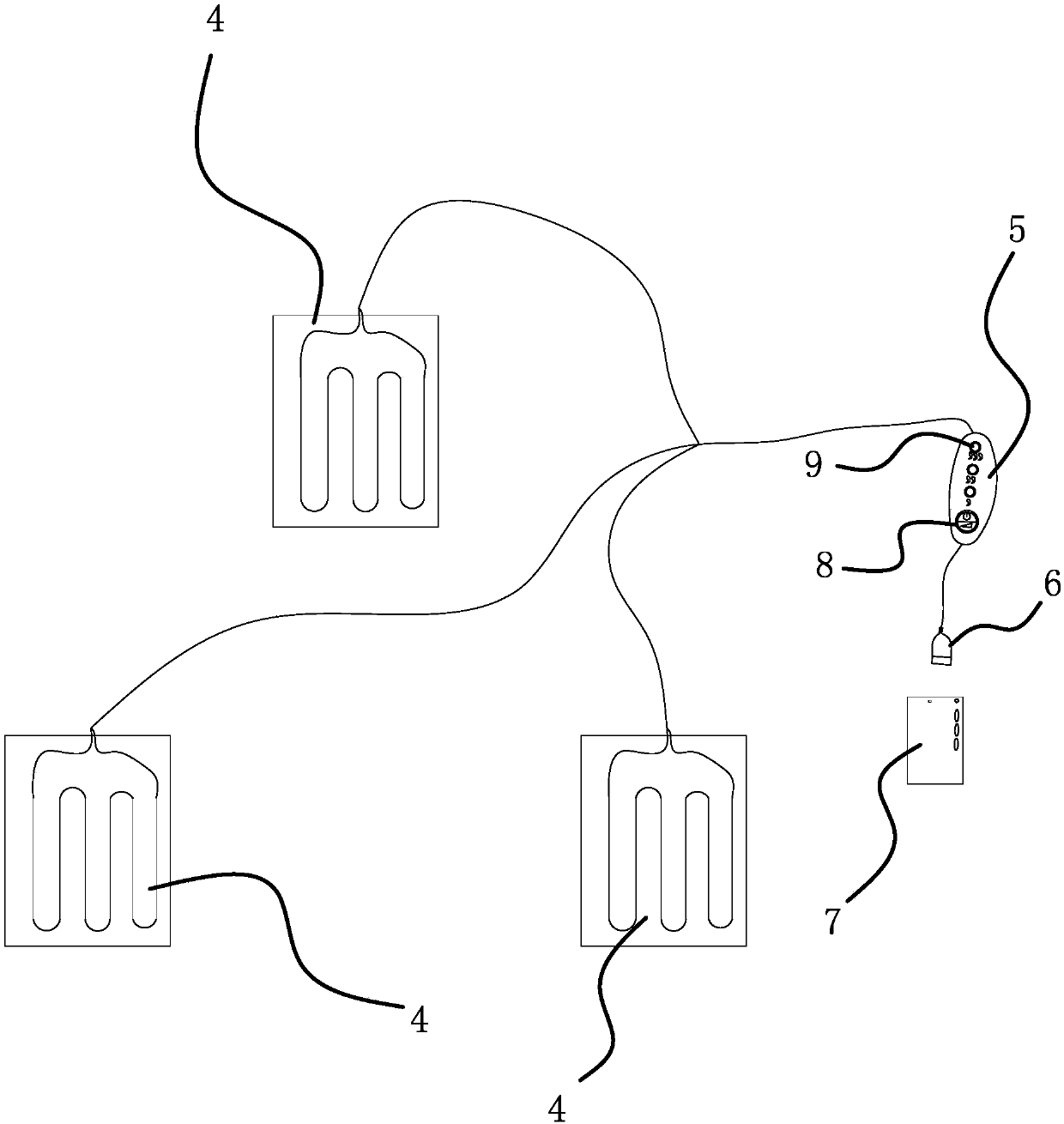

[0017] Such as figure 1 , figure 2 As shown, the carbon fiber heating leather garment includes a leather garment body, a leather garment pocket, and a leather garment shoulder 1. There are three pieces of leather material 2 and three carbon fiber composite cloth 3 on the leather garment shoulder 1. The carbon fiber composite cloth 3 is composed of two layers of carbon fiber fabric and TPU film. , the carbon fiber fabric is located on the inner side of the leather garment, and the shoulder 1 of the leather garment has a triangular hole facing outward, the triangular hole is an inverted triangle, the carbon fiber composite cloth 3 is arranged in a long strip shape, and the two ends of the carbon fiber composite cloth 3 are connected to the edge of the triangular hole by sewing, T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com