Bag dust collecting tank for wood industry

A bag dust removal and wood industry technology, applied in the direction of dispersed particle separation, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of deteriorating working environment, large amount, unfavorable continuity of dust removal work, etc., and achieve stable function and convenient use , design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

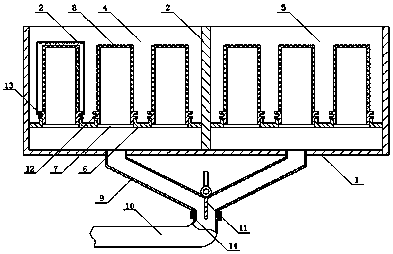

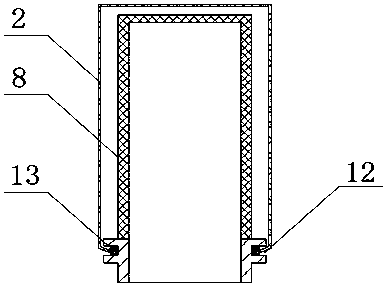

[0012] A cloth bag dust removal box for wood industry according to the present invention includes a box body 1 and a dust removal bag 2. The box body 1 is a cuboid with an open top, and a partition 3 is arranged in the middle to divide it into a left chamber 4. and the right chamber 5, the left chamber 4 and the lower part of the right chamber 5 are all fixedly installed with a horizontal plate 6, and the circular socket 7 is evenly distributed on the described horizontal plate 6, and the circular socket 7 is all plugged and installed. A circular cage 8 with an opening at the bottom. The circular cage 8 is covered with a dust bag 2. The bottoms of the left chamber 4 and the right chamber 5 are provided with a branch 9 connected to the main pipeline 10. , the triangular connection between the branch road 9 and the main road 10 is provided with a switch paddle 11 .

Embodiment 2

[0014] A cloth bag dust removal box for wood industry according to the present invention includes a box body 1 and a dust removal bag 2. The box body 1 is a cuboid with an open top, and a partition 3 is arranged in the middle to divide it into a left chamber 4. and the right chamber 5, the left chamber 4 and the lower part of the right chamber 5 are all fixedly installed with a horizontal plate 6, and the circular socket 7 is evenly distributed on the described horizontal plate 6, and the circular socket 7 is all plugged and installed. A circular cage 8 with an opening at the bottom. The circular cage 8 is covered with a dust bag 2. The bottoms of the left chamber 4 and the right chamber 5 are provided with a branch 9 connected to the main pipeline 10. , the triangular connection between the branch road 9 and the main road 10 is provided with a switch paddle 11 . The bottom opening of the circular cage body 8 is plugged into the circular socket 7, the bottom of the circular ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com