Automatic pipe expanding system three-working-station fin assembly code fetching unit

A three-station, tube-expanding technology, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problems of low stacking efficiency, low production efficiency, tube expansion of fin assemblies, etc., so as to improve the efficiency of grabbing and stacking , Prevent inconvenient code retrieval and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

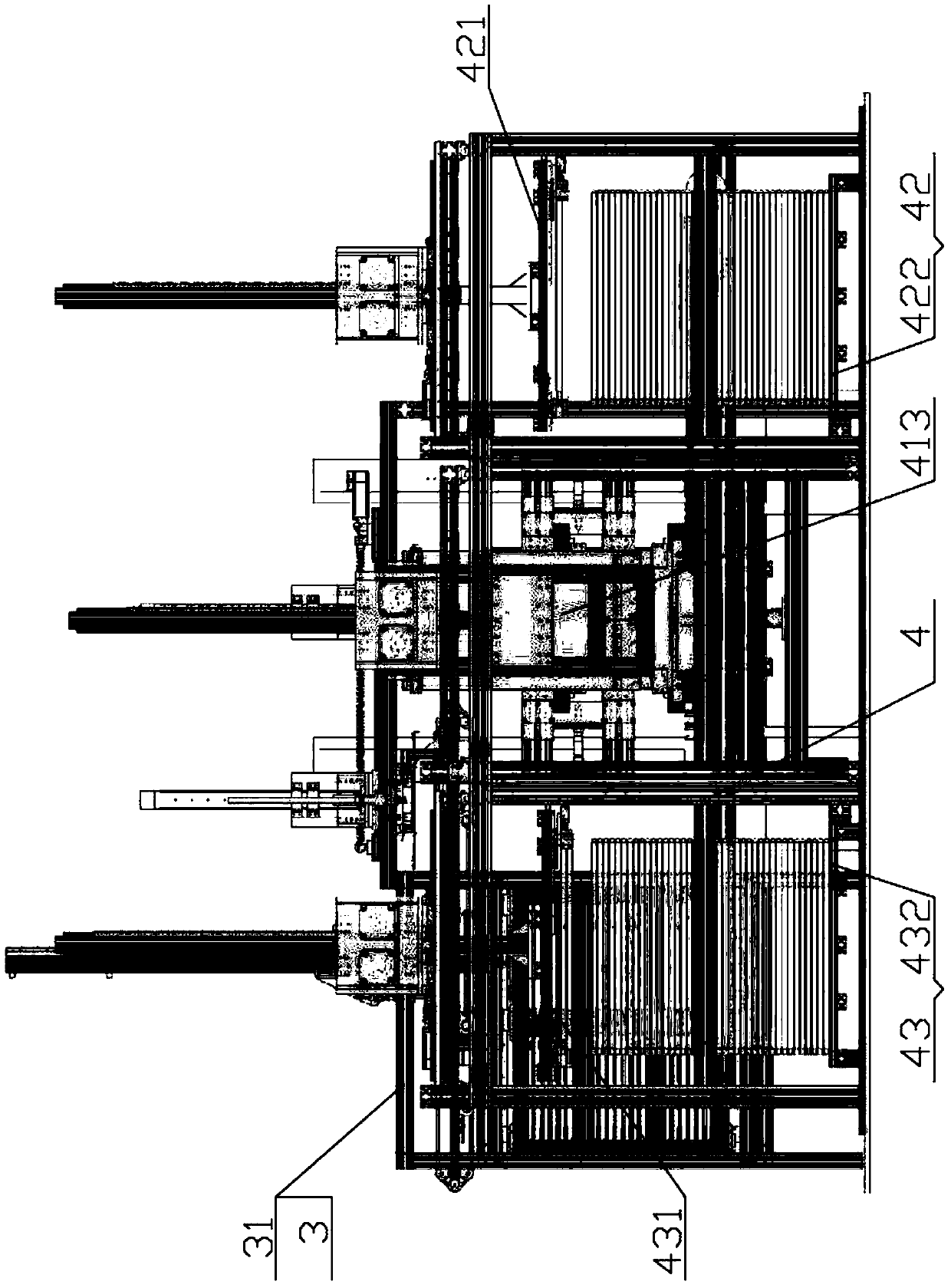

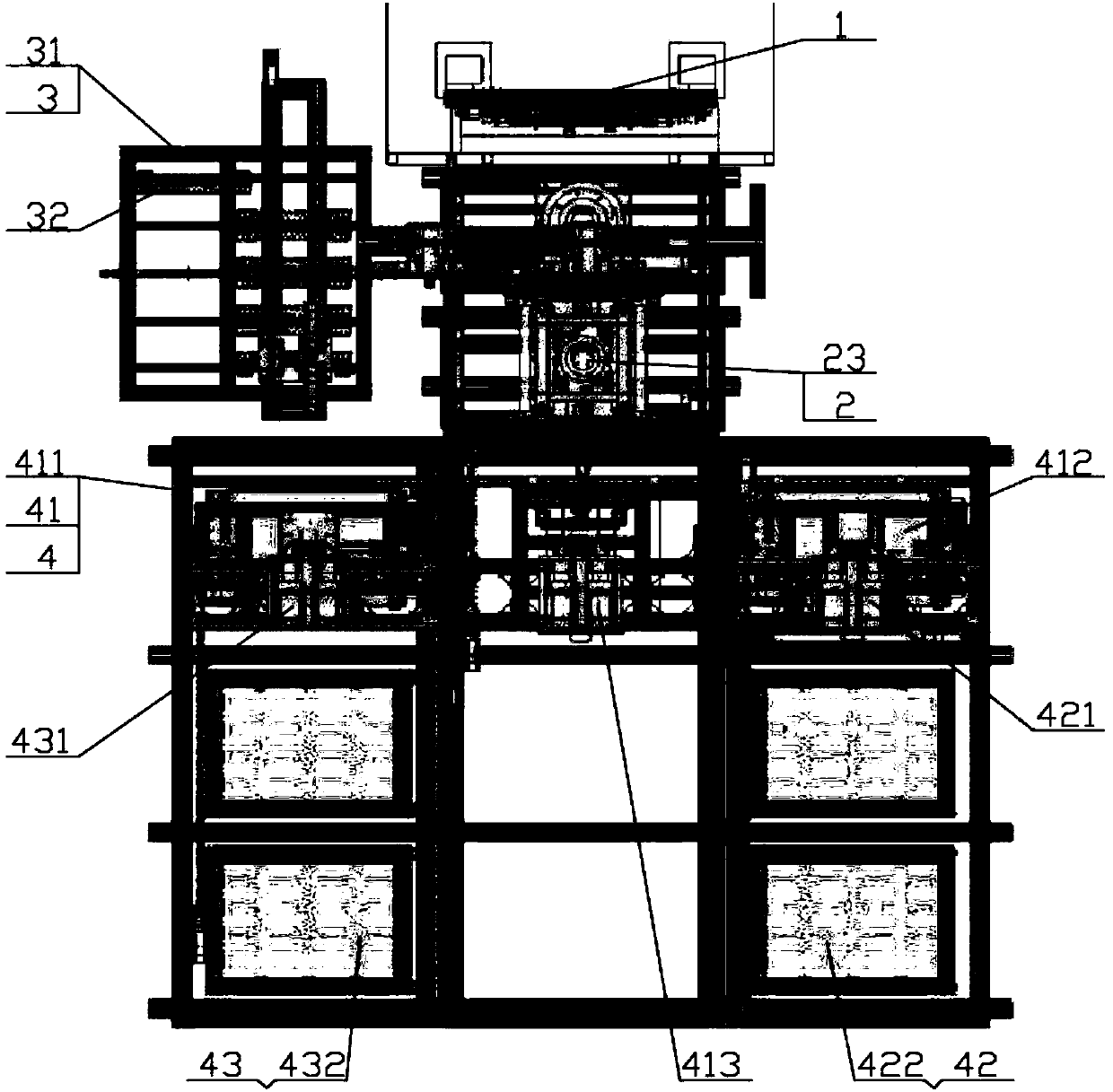

[0039] Below in conjunction with accompanying drawing, the present invention will be further described (the following description takes the direction where the tube expander 1 is in the automatic tube expansion system of the whole air conditioner fin assembly as the front, the left and right horizontal directions as the X coordinate, and the front and rear horizontal directions as Y Coordinates, take the vertical direction as the Z coordinate, take the direction along the X coordinate direction axis as the rotation axis as the A coordinate, and take the direction along the Z coordinate direction axis as the rotation axis as the C coordinate).

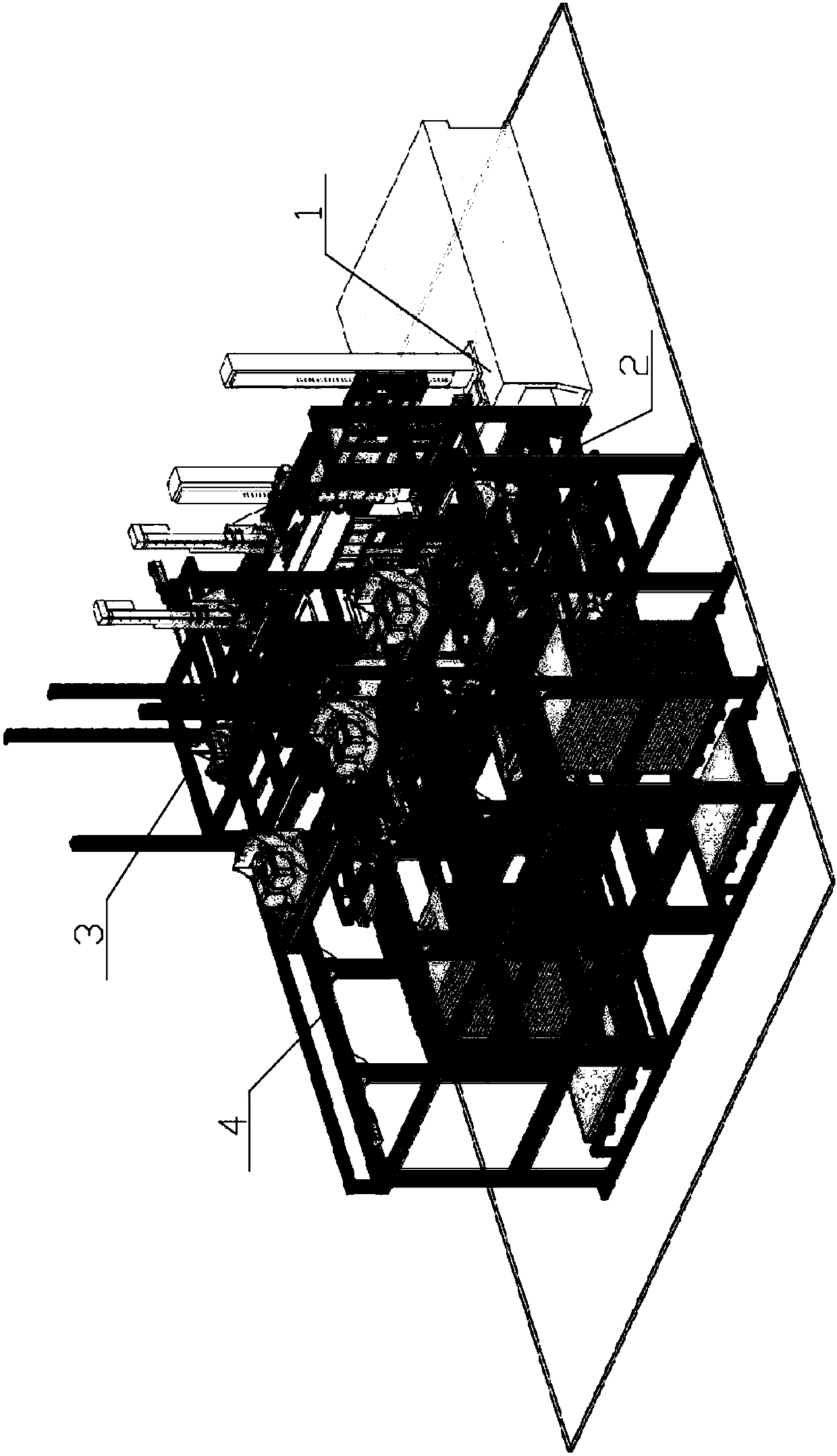

[0040] Such as Figure 1 to Figure 4 As shown, the air conditioner fin assembly automatic tube expansion system includes a tube expander 1, a fin assembly indexing accompanying unit 2, a supporting steel plate insertion unit 3, a three-station fin assembly code fetching unit 4 and an electric control unit.

[0041] The tube expander 1 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap