Swerving chain plate machine stable in running

A technology of smooth operation, chain plate machine, applied in the direction of conveyor, transportation and packaging, can solve the problems of centrifugal movement of chain plate, chain damage, inability to maintain level, etc., to achieve stable operation, simple and firm structure, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

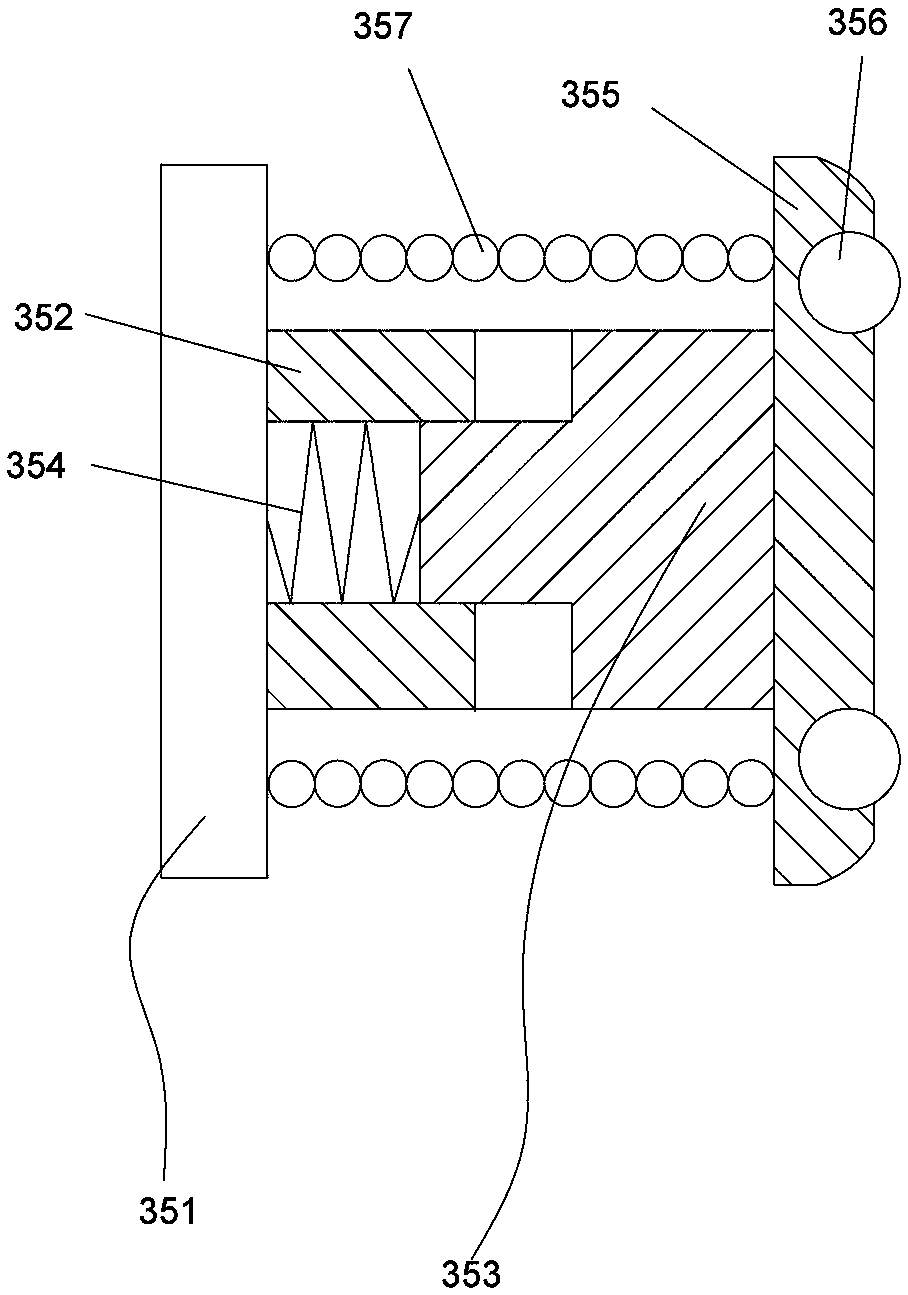

[0018] Embodiment 1: Embodiment 1, a kind of turning chain plate machine of stable operation, comprises frame 1, the arc-shaped guide rail 2 that is arranged on described frame 1, is arranged on described frame 1 and extends described arc Shaped guide rail 2 sliding conveying device 3, described conveying device 3 is driven to slide on described arc guide rail 2 by driving motor; Described conveying device 3 comprises the rotating shaft 31 that is located on the described frame 1, and described rotating shaft 31 Driven by the driving motor to rotate, the rotating shaft 31 is provided with at least two sprockets 32, the sprockets 32 are equipped with chains 33, and the top and bottom of the chains 33 are connected with chain plates 34; The end of the chain plate 34 is provided with an elastic adjustment mechanism 35 which is in rolling contact with the arc guide rail 2 . In this embodiment, the end of the chain plate 34 is in contact with the arc guide rail 2 through the elasti...

Embodiment 2

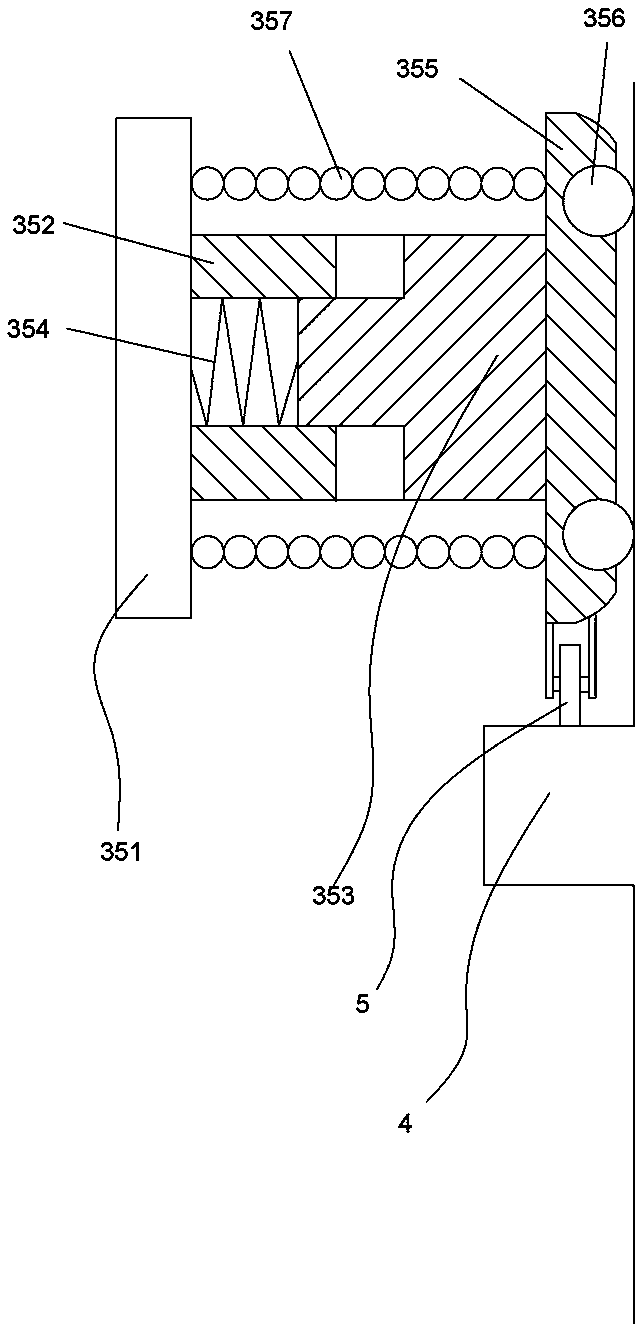

[0020] Embodiment 2 is different from Embodiment 1. The arc-shaped guide rail 2 is provided with a stopper 4 that protrudes toward the chain plate 34 and extends along the extending direction of the arc-shaped guide rail 2 . The bottom is provided with a roller 5 which is in rolling contact with the upper end surface of the limiting part 4 . With this setting, the roller 5 directly supports the chain plate 34 and the objects on it, the two chains 33 are basically free of force in the vertical direction, the chain 33 runs smoothly, has a long service life, and the chain plate 34 does not deflect vertically , the objects on the chain plate 34 are not easy to slide and not easy to be damaged.

Embodiment 3

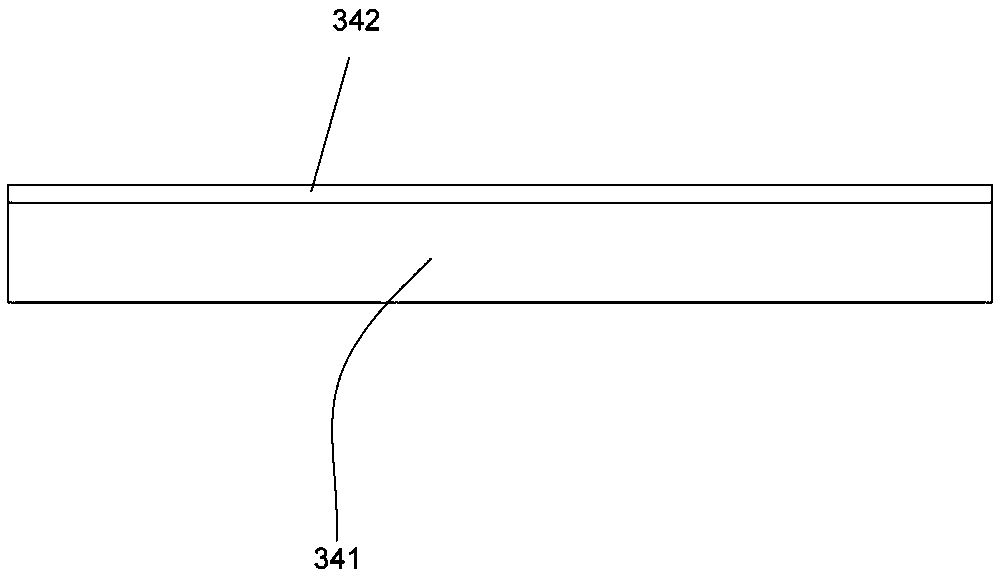

[0021] In Embodiment 3, the chain plate 34 includes a base layer 341 and a hard chromium plating layer 342 disposed on the base layer 341 . The hard chromium plating layer 342 improves the properties of the chain plate such as hardness, wear resistance, temperature resistance and corrosion resistance. Extended service life.

[0022] All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com