Ecological high-ductility cement-based composite material and method prepared from organic waste

A technology of organic waste and composite materials, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as the decrease of fracture toughness of cement-based material matrix, restrictions on the popularization and application of HDCC, and weak transition zones , to achieve the effect of being conducive to ecological construction, large-scale project application prospects, and high ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

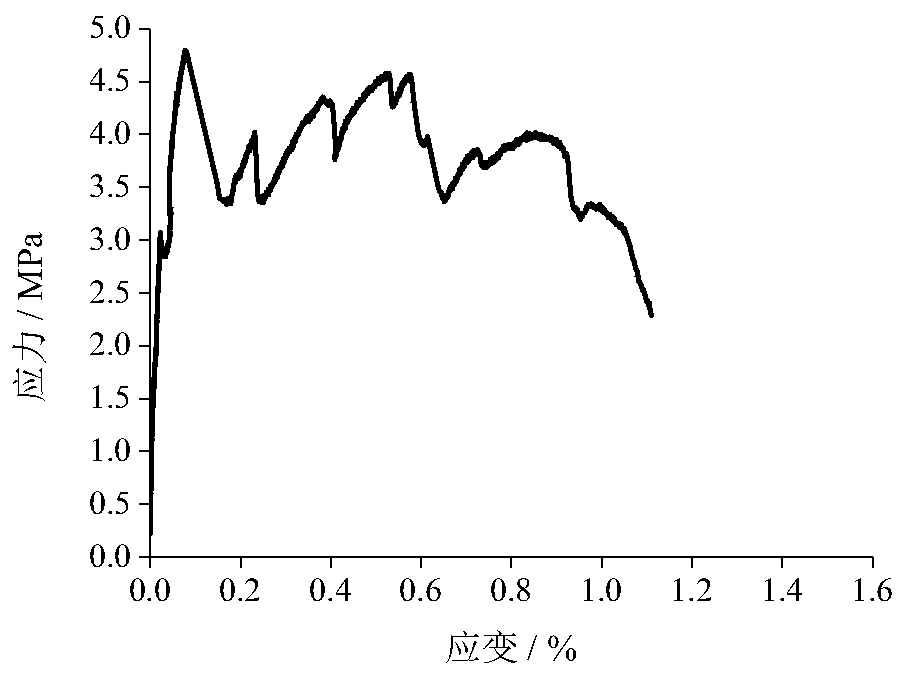

Embodiment 1

[0030] The matching ratio of the ECO-HDCC of the present invention is shown in the following table 1:

[0031] Table 1 ECO-HDCC mix ratio (mass ratio)

[0032]

[0033] The cement used above is ordinary portland cement with strength grade 42.5, the particle size of the river sand is 0.15-1.18mm, and the fineness modulus is 1.68, and the organic waste is asphalt milling material, the particle size is 0.15-1.18mm, The modulus is 1.72, the viscosity of the viscosity modifier is 20000mPa.s, and the fiber type is polyvinyl alcohol fiber.

[0034] The preparation steps are as follows:

[0035] 1) Dry mix cement, fly ash, solid water reducing agent, viscosity modifier, fine sand and asphalt milling material in a mixer for 90 seconds, and the rotation frequency of the mixer blade is 130 rpm;

[0036] 2) Add water and stir for 3 minutes, and the rotation frequency of the mixer blade is 285 rpm;

[0037] 3) Add fiber and stir for 2 minutes, and the rotation frequency of the mixer ...

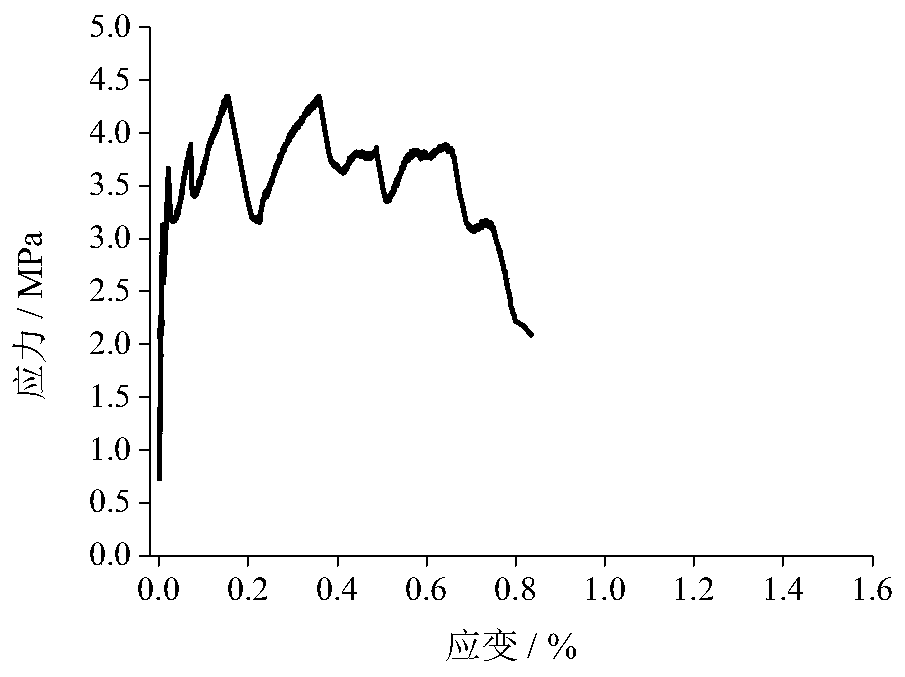

Embodiment 2

[0040] The matching ratio of the ECO-HDCC of the present invention is shown in the following table 2:

[0041] Table 2 ECO-HDCC mix ratio (mass ratio)

[0042]

[0043] The cement used above is ordinary Portland cement of strength grade 52.5, the organic waste is waste rubber particles, the particle size is 0.15-1.18mm, the fineness modulus is 1.74, the viscosity of the viscosity modifier is 15000mPa.s, and the fiber type is polyethylene fiber.

[0044] The preparation steps are as follows:

[0045] 1) Dry mix cement, fly ash, solid water reducing agent, viscosity modifier and waste rubber particles in a mixer for 1 minute, and the rotation frequency of the mixer blades is 140 rpm;

[0046] 2) Add water and stir for 3 minutes, and the rotation frequency of the mixer blade is 280 rpm;

[0047] 3) Add fiber and stir for 2 minutes, and the rotation frequency of the mixer blade is 280 rpm;

[0048] 4) Install the mold, remove the mold after 48 hours, and standardize for 28 ...

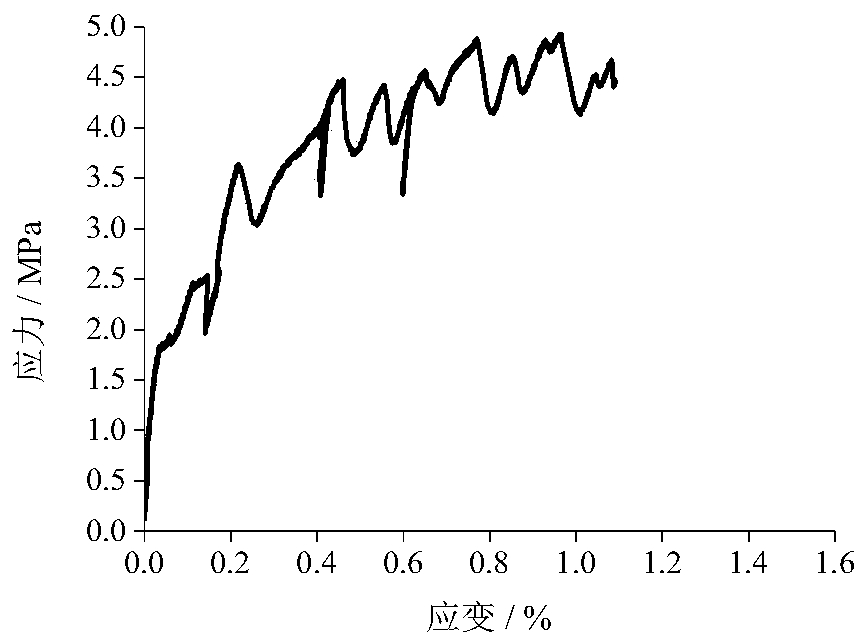

Embodiment 3

[0050] The matching ratio of the ECO-HDCC of the present invention is shown in the following table 3:

[0051] Table 3 ECO-HDCC mix ratio (mass ratio)

[0052]

[0053] The cement used above is ordinary Portland cement with strength grade 42.5, the particle size of the river sand is 0.15-1.18mm, and the fineness modulus is 1.68. The organic waste is waste epoxy resin particles, the particle size is 0.15-1.18mm, fine The degree modulus is 1.81, the viscosity of the viscosity modifier is 20000mPa.s, and the fiber type is polypropylene fiber.

[0054] The preparation steps are as follows:

[0055] 1) Dry mix cement, fly ash, viscosity modifier, fine sand and waste epoxy resin particles in a mixer for 2 minutes, and the rotation frequency of the mixer blades is 130 rpm;

[0056] 2) After uniformly mixing water and liquid superplasticizer, stir for 210 seconds, and the rotation frequency of the mixer blade is 140 rpm;

[0057] 3) Add fiber and stir for 150 seconds, and the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com