A kind of fluorine-containing graphene oxide modified polyurethane coating and its preparation method and application

A technology of graphene modification and polyurethane coatings, which is applied in polyurea/polyurethane coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of reduced electrical conductivity of materials, achieve improved mechanical properties, simple preparation process, The effect of improving hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

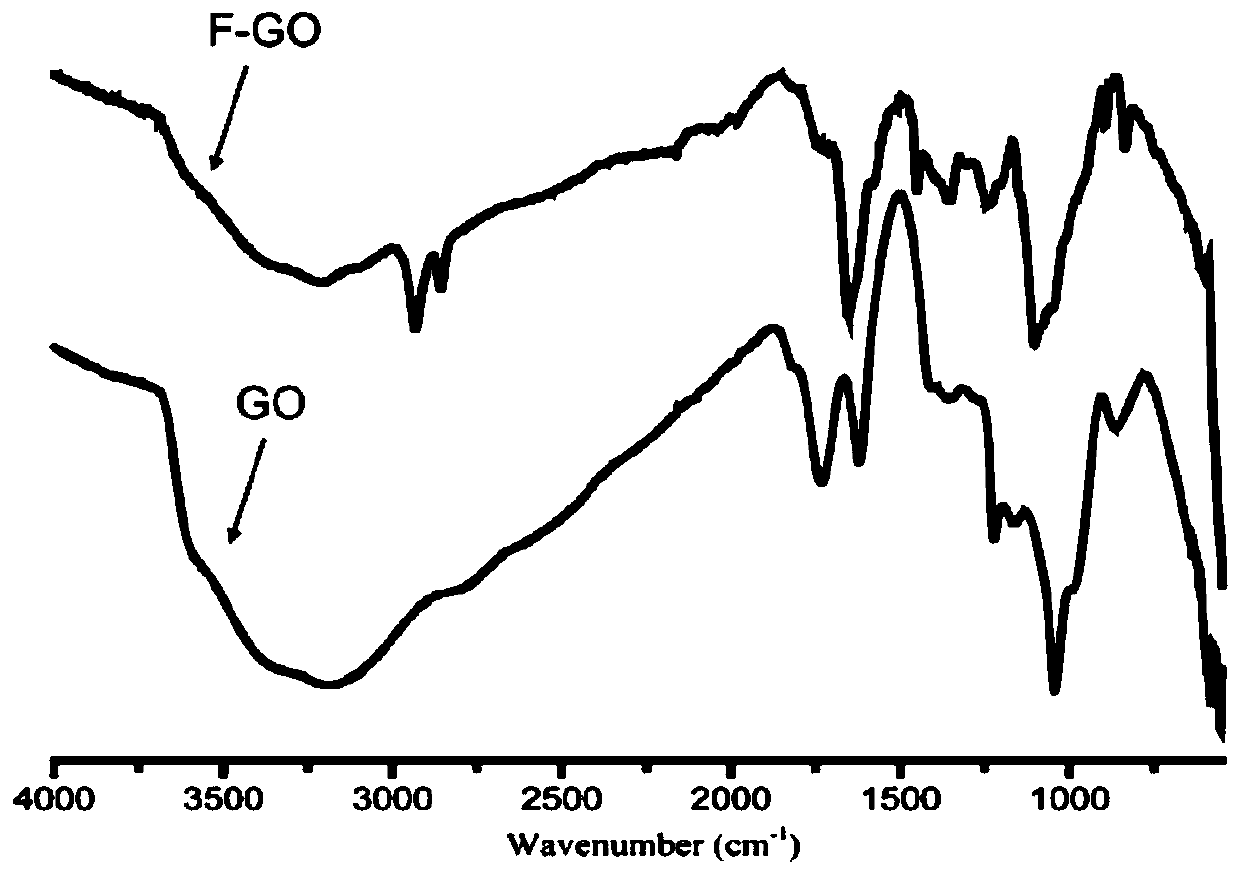

[0030] 1) Preparation of fluorine-containing graphene oxide:

[0031] Put the graphite powder into the flask, and add H with a mass concentration of 98% 2 SO 4 and H at a mass concentration of 85% 3 PO 4 ; Under ice bath conditions, slowly add KMnO 4 , keep the mixed solution at 40-50°C and stir the reaction; after the mixed solution obtained from the reaction is cooled to room temperature, it is poured on ice cubes made of deionized water, and H2O with a mass concentration of 30% is added under stirring 2 o 2 , at this time, the mixed solution turns from purple-black to bright yellow; after the mixed solution is filtered, it is centrifuged and washed 5 times with 10% HCl to remove the residue; it is washed and centrifuged for 5 times, then freeze-dried and dispersed by ultrasonic to obtain Brown graphene oxide GO; 0.1g prepared graphene oxide (GO) and 0.1g dicyclohexylcarbodiimide (DCC) were ultrasonically dispersed in a round bottom flask with 100ml ethanol, and then 0....

Embodiment 2

[0036] Preparation of fluorine-containing graphene oxide:

[0037] Put the graphite powder into the flask, and add H with a mass concentration of 98% 2 SO 4 and H at a mass concentration of 85% 3 PO 4 ; Under ice bath conditions, slowly add KMnO 4 , keep the mixed solution at 40-50°C and stir the reaction; after the mixed solution obtained from the reaction is cooled to room temperature, it is poured on ice cubes made of deionized water, and 30% H 2 o 2, at this time, the mixed solution turns from purple-black to bright yellow; after the mixed solution is filtered, it is centrifuged and washed 5 times with HCl with a mass concentration of 10% to remove the residue; it is washed and centrifuged 5 times, then freeze-dried, dispersed and ultrasonicated to obtain Brown graphene oxide GO; 0.1 g of prepared graphene oxide (GO) and dicyclohexylcarbodiimide (DCC) were ultrasonically dispersed in a round-bottomed flask filled with ethanol. Then 0.4 g of trifluoroethanol was added...

Embodiment 3

[0041] 1) Preparation of fluorine-containing graphene oxide:

[0042] Put the graphite powder into the flask, and add H with a mass concentration of 98% 2 SO 4 and H at a mass concentration of 85% 3 PO 4 ; Under ice bath conditions, slowly add KMnO 4 , keep the mixed solution at 40-50°C and stir the reaction; after the mixed solution obtained from the reaction is cooled to room temperature, it is poured on ice cubes made of deionized water, and H2O with a mass concentration of 30% is added under stirring 2 o 2 , at this time, the mixed solution turns from purple-black to bright yellow; after the mixed solution is filtered, it is centrifuged and washed 5 times with HCl with a mass concentration of 10% to remove the residue; it is washed and centrifuged 5 times, then freeze-dried, dispersed and ultrasonicated to obtain Brown graphene oxide GO; 0.2 g of prepared graphene oxide (GO) and 0.2 g of dicyclohexylcarbodiimide (DCC) were ultrasonically dispersed in a round-bottomed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com