Special boiling-bleaching process for pure cotton knitted fabrics

A pure cotton needle and knitted fabric technology, which is applied in the field of boiling and bleaching technology, can solve the problems of poor cotton fabric feel, unsatisfactory impurity treatment effect, and large cotton fiber damage, so as to achieve soft and fluffy hand feeling, improve impurity removal effect, and not The effect of causing mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: a kind of process that is specially used in the boiling and bleaching of pure cotton knitted fabric, comprises the steps:

[0027] (1) Immerse the pure cotton knitted fabric in hot water at 93°C for 5 minutes, and then flick the pure cotton knitted fabric at a specific frequency while it is hot. 10min in vibrating cold water;

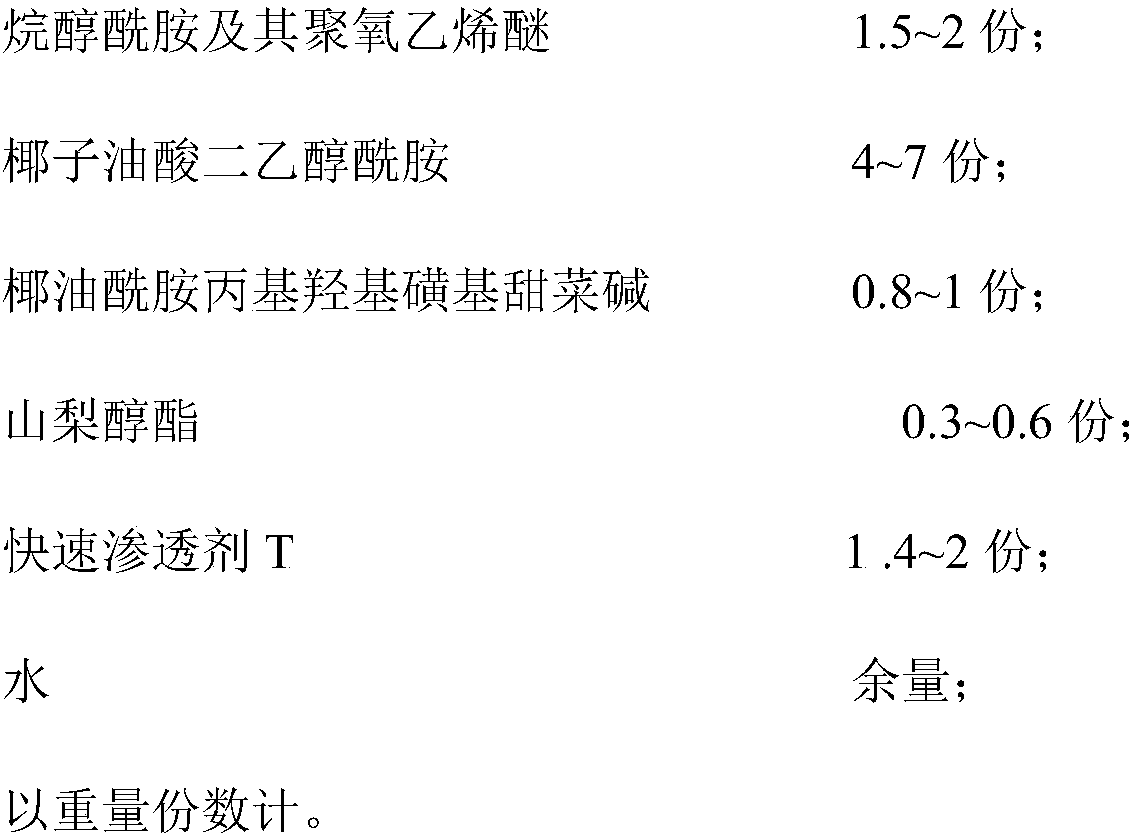

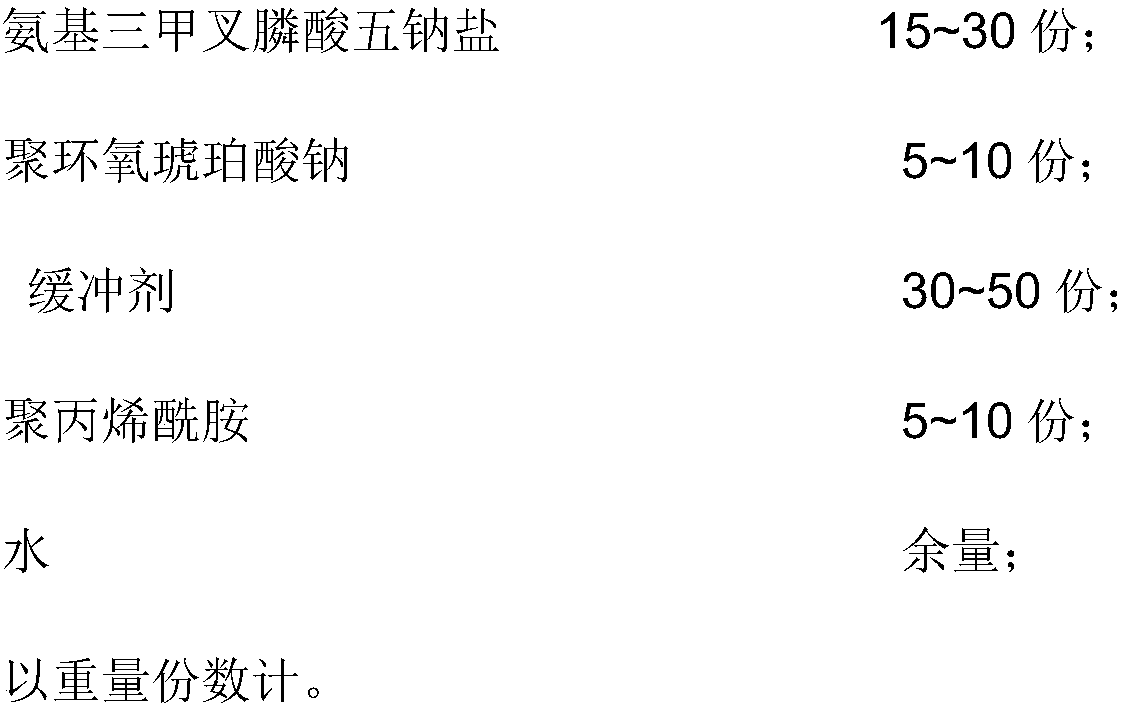

[0028] (2) Arrange the pure cotton knitted fabric into the mixed cleaning agent at 50°C for 3 minutes; then keep the temperature condition unchanged, add an appropriate amount of caustic soda aqueous solution, and the pure cotton knitted fabric lasts for 3 minutes in an alkaline environment;

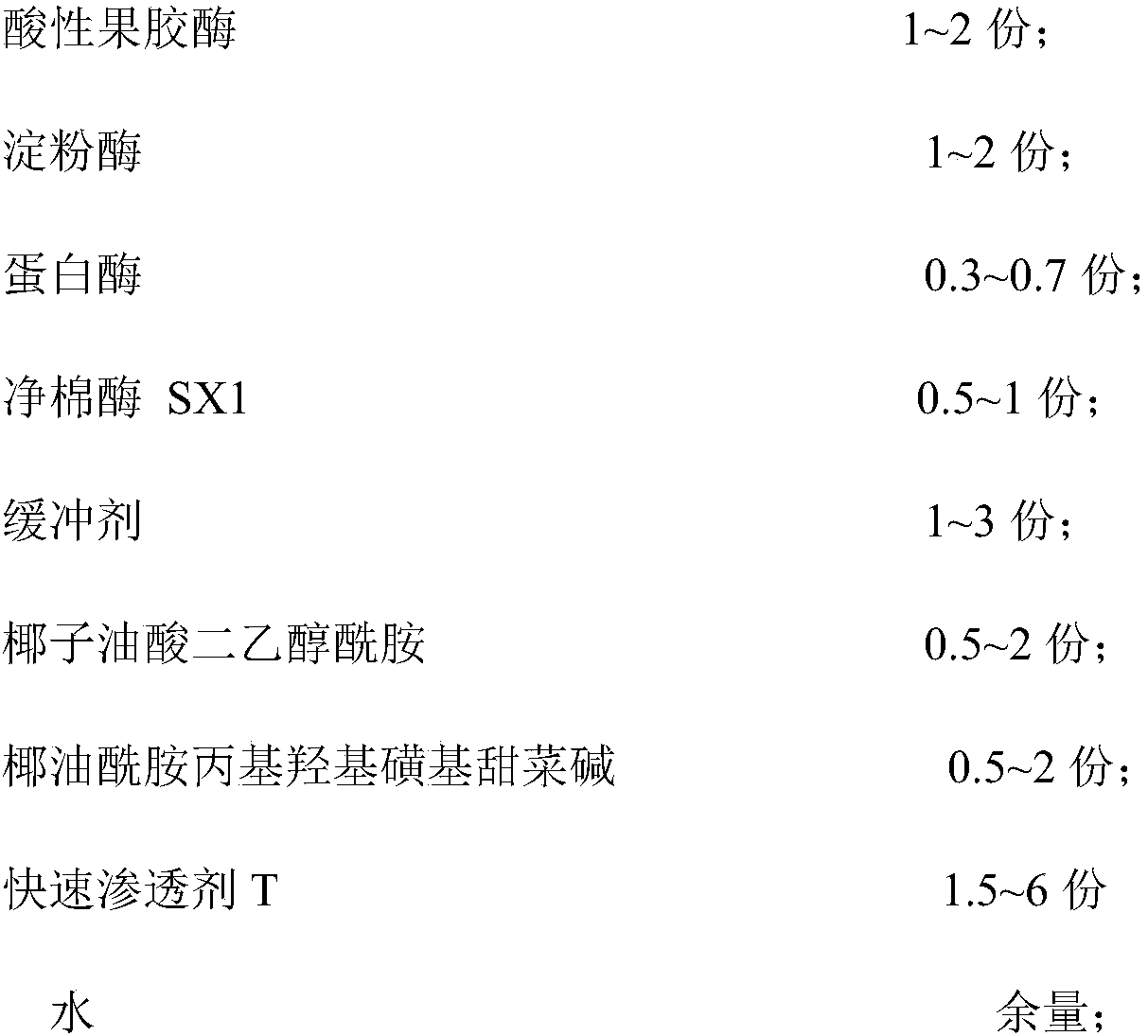

[0029] (3) Immerse the pure cotton knitted fabric in the bleaching mixture at 50°C, keep it warm for 3 minutes, then wash it in hot water at 95°C within 3 minutes, keep it warm for 45 minutes, cool it down to 77°C naturally, and put it in acetic acid solution at 50°C Medium peracid treatment;

[0030] (4) Arrange the pure cotton knitting int...

Embodiment 2

[0047] Embodiment 2: a kind of scouring and bleaching process that is specially used for pure cotton knitted fabrics, comprises the steps:

[0048] (1) Immerse the pure cotton knitted fabric in hot water at 90°C for 6 minutes, then flick the pure cotton knitted fabric at a specific frequency while it is hot. The flicking process lasts for 8 minutes, and then place the pure cotton knitted fabric 15min in vibrating cold water;

[0049] (2) Arrange the pure cotton knitted fabric into the mixed cleaning agent at 40°C for 6 minutes; then keep the temperature condition unchanged, add an appropriate amount of caustic soda aqueous solution, and the pure cotton knitted fabric lasts for 4 minutes in an alkaline environment;

[0050] (3) Immerse the pure cotton knitted fabric in the bleach mixture at 40°C, keep it warm for 5 minutes, then wash it in hot water at 93°C within 5 minutes, keep it warm for 50 minutes, cool it down to 75°C naturally, and put it in 40°C acetic acid solution Me...

Embodiment 3

[0067] Embodiment 3: a kind of process that is specially used in the boiling and bleaching of pure cotton knitted fabric, comprises the following steps:

[0068] (1) Immerse the pure cotton knitted fabric in hot water at 95°C for 4 minutes, then flick the pure cotton knitted fabric at a specific frequency while it is hot. 5min in vibrating cold water;

[0069] (2) Arrange the pure cotton knitted fabric into the mixed cleaning agent at 52°C for 6 minutes; then keep the temperature condition unchanged, add an appropriate amount of caustic soda aqueous solution, and keep the pure cotton knitted fabric in the alkaline environment for 2 minutes;

[0070] (3) Immerse the pure cotton knitted fabric in the bleaching mixture at 52°C, keep it warm for 2 minutes, then wash it in hot water at 98°C within 2 minutes, keep it warm for 40 minutes, cool it down to 78°C naturally, and put it in acetic acid solution at 52°C Medium peracid treatment;

[0071] (4) Arrange the pure cotton knittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com