Guarding device for building construction

A technology of building construction and protective devices, which is applied in the direction of buildings, building types, and the use of liquid separation agents, etc., can solve the problems of plastic plate enclosure rollover, iron plate damage, and more time-consuming and manpower-consuming problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

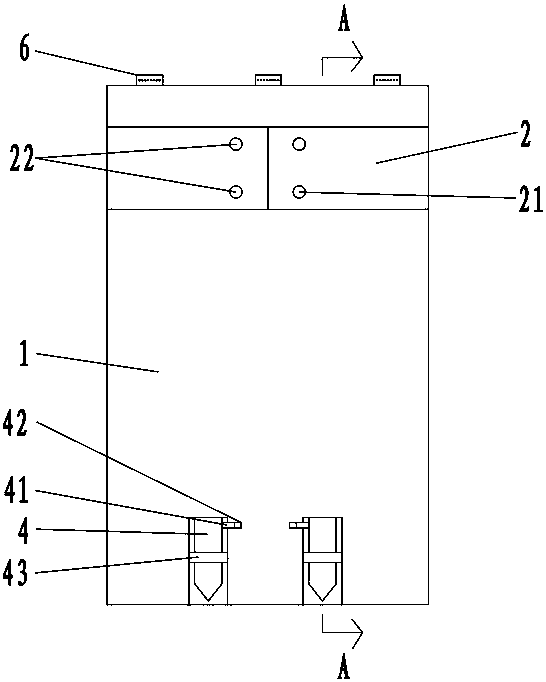

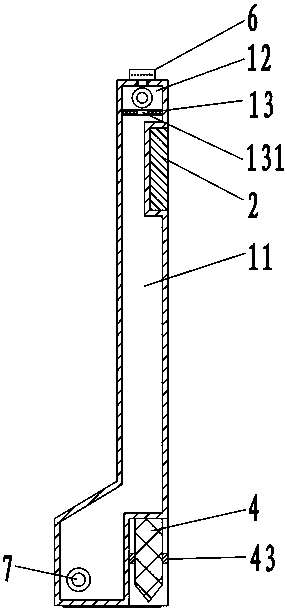

[0025] Such as Figures 1 to 8 As shown in one of the above, the device of the present invention is used for the enclosure of the building construction site, and it includes a device body 1 with a shoe-shaped structure and a hollow interior. The first water inlet 3 and the first water outlet 5 and the first water inlet 3 and the first water outlet 5 are detachably plugged with first pipe plugs 33, 53, the width direction of the device main body 1 One side is the plane side and the upper part of the plane side is rotatably provided with a connecting plate 2, one end of the connecting plate 2 is rotatably connected to the horizontal edge of the plane side of the device main body 1, and the other end of the connecting plate 2 is provided with a pair of opposite The other side of the connection hole 21 and the plane side is adapted to the height of the connection plate 2 is provided with a connection column 22 suitable for the size of the connection hole 21, and the several device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com