Double-rotation planer tool for planing grafted scion branches

A rotary planer and double-rotation technology, applied in the field of wood planing tools, can solve the problems of not being too large, simple and high survival rate, not easy to round, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

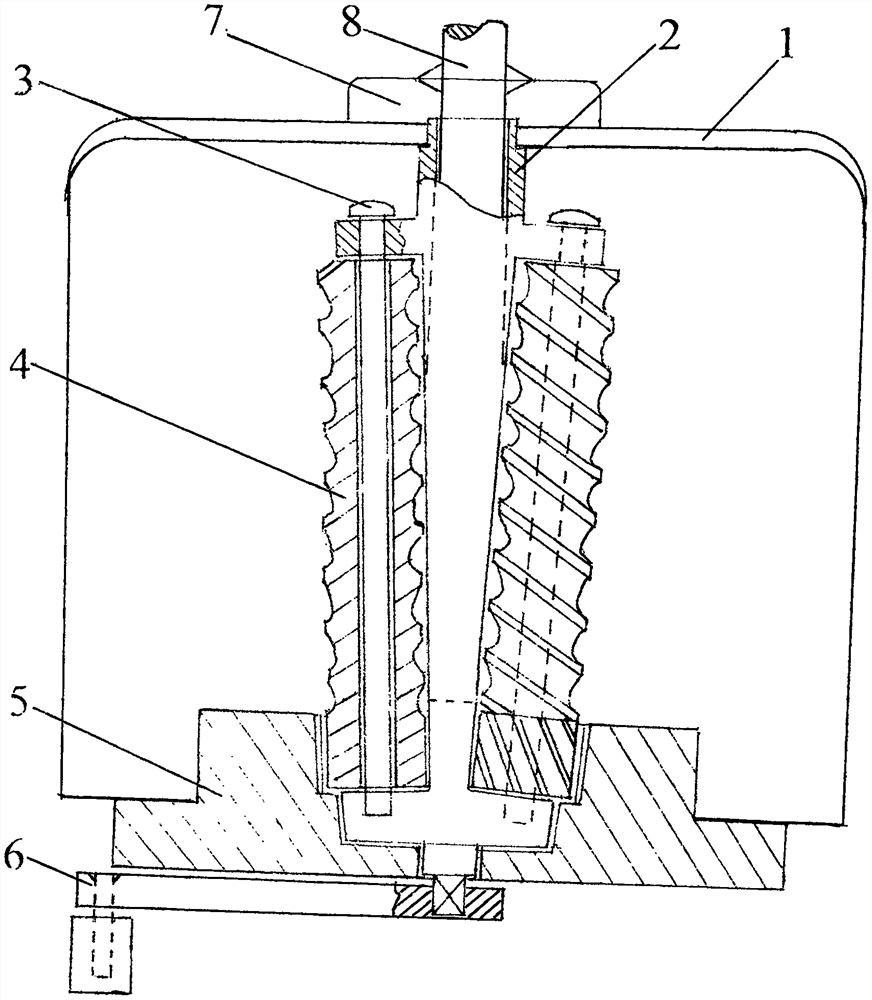

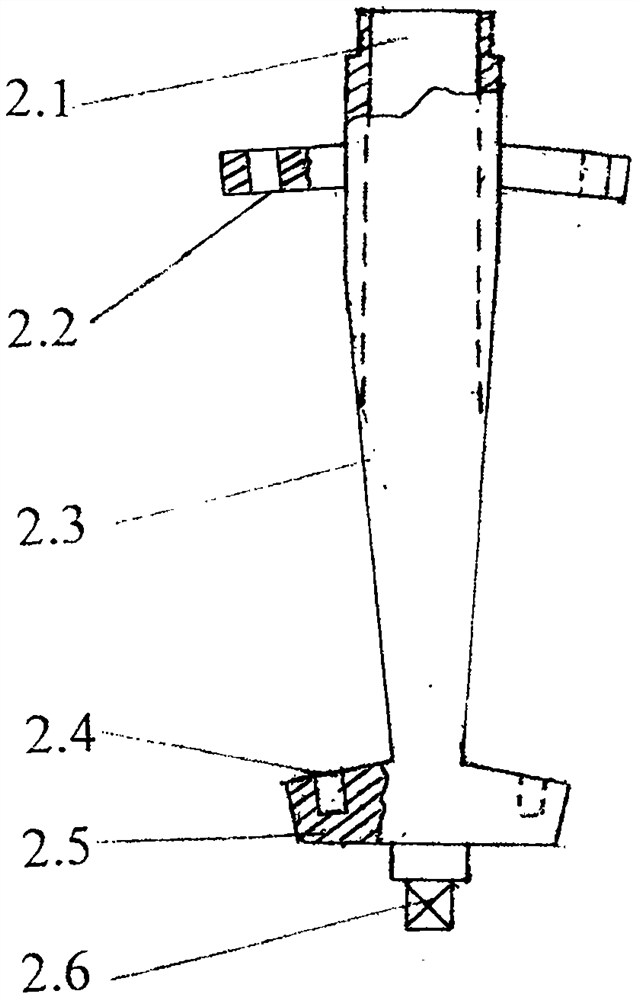

[0013] A double rotary planer for planing grafted scion branches, the specific structure is set in this way; the rotary knife rest (2) is made of aluminum or copper casting, will not rust, and the rotary knife rest (2) is a tube-shaped as the main body , the upper opening of the pipe is provided with a step (2.1), and the step (2.1) is inserted into the through hole of the casing (1) to play a positioning role. The inner hole of the pipe is to place planed scion branches (8). Both sides are oblique angles (2.3), two rotary planers (4) are placed obliquely at 180 degrees respectively, the inclination is 20:1~30:1, and two pivot pins (3) are inserted into the rotary tool holder steps (2.2) In the hole, pass through the rotary planer (4) in the middle, and insert the shaft head into the hole of the shaft pin positioning hole (2.4) of the lower seat of the tool holder (2.5). The planer (4) is made of alloy tool steel. The rake angle of the rotary planer blade (4.1) is 15° to 25°. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com