Switch tool for cylinder valve of high pressure gas cylinder

A high-pressure gas cylinder, switch tool technology, applied in the valve operation/release device, valve details, valve device and other directions, can solve the problems of inability to judge the health status of the equipment, higher purity requirements, and more effort, etc. To achieve the effect of strong practical value, easy to carry and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

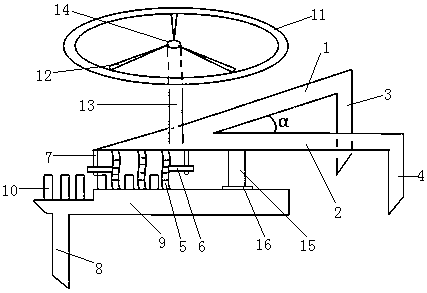

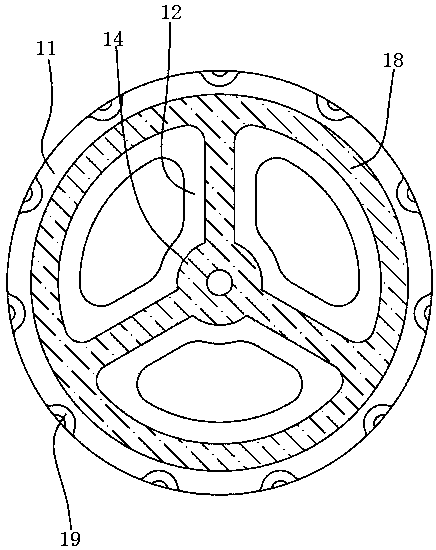

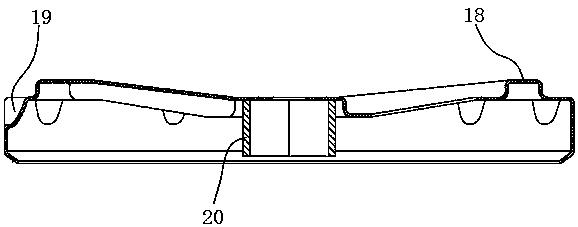

[0037] Take the diameter of the high-pressure gas cylinder valve 17 as an example to design the specific structural dimensions of the switch tool in the present invention, the length of the first support arm 1 and the second support arm 2 is 5cm, and the included angle α is preferably 30° -60°, in the present embodiment, the included angle α=36°; the lengths of the first fixed jaw 3 and the second fixed jaw 4 are 3cm, and the distance from the other end of the third support arm 9 to the movable jaw 8 is 4cm, The length of movable jaw 8 is 1.5cm, and the handwheel outer ring 11 diameter of handwheel is 8cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com