Electronic ballast experiment platform for driving ultraviolet lamp and optimization method of driving power of ultraviolet lamp

A technology for electronic ballasts and ultraviolet lamps, which is applied in the direction of measuring electric power, using electric radiation detectors for photometry, and electrical devices, etc. Power, short life of UV lamps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

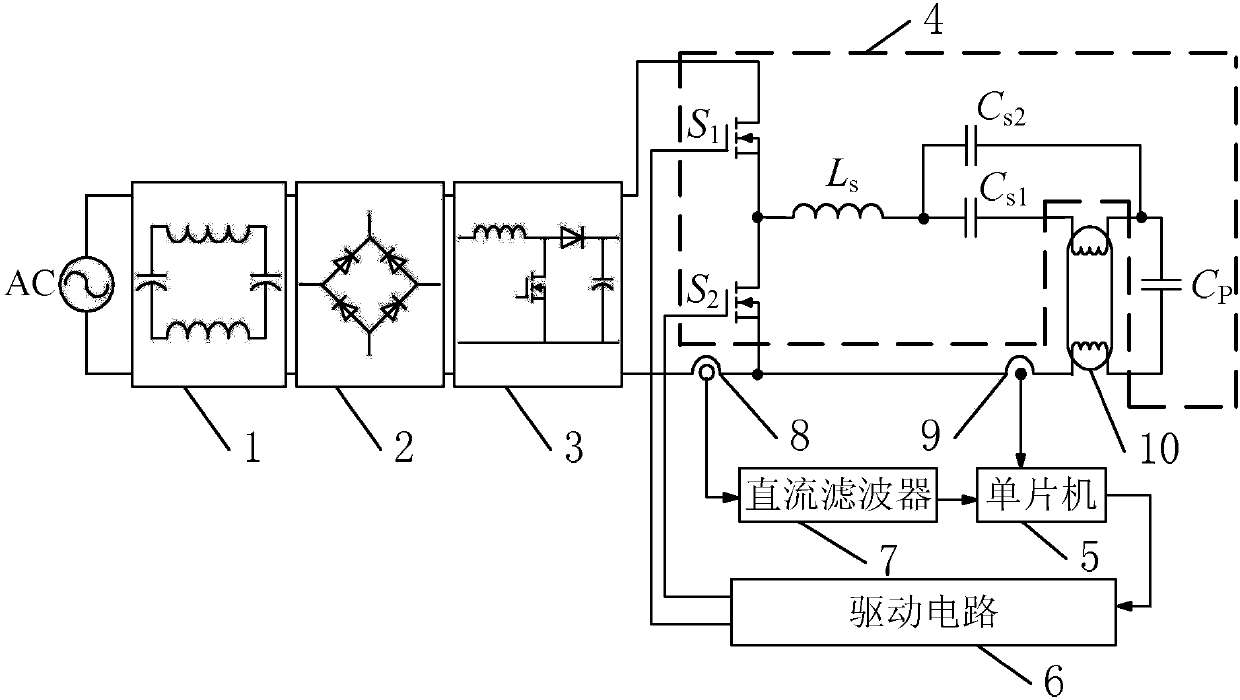

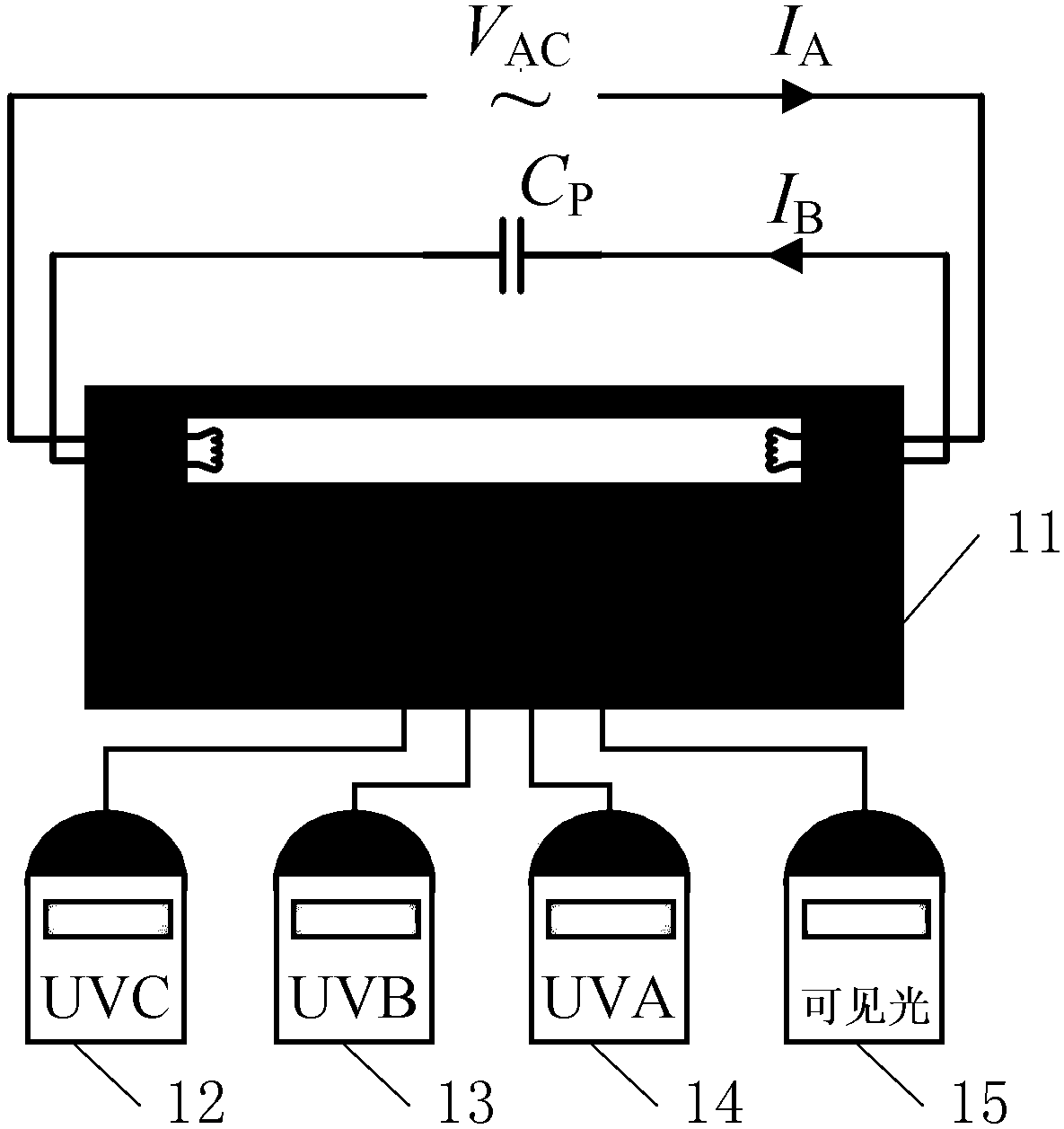

[0060] Specific implementation mode one: see figure 1 and figure 2 Describe this embodiment mode, a kind of electronic ballast experimental platform for driving ultraviolet lamp described in this embodiment mode, it comprises EMI filter 1, full-bridge rectifier 2, power factor correction circuit 3, half-bridge LCC resonant circuit 4 , SCM 5, drive circuit 6, DC filter 7, current acquisition device 8, voltage acquisition device 9, black box 11, UVA measuring instrument 12, UVB measuring instrument 13, UVC measuring instrument 14 and visible light measuring instrument 15;

[0061] After the 220V single-phase alternating current passes through the EMI filter 1 to eliminate electromagnetic interference, it is rectified by the full-bridge rectifier 2 in turn, and the power factor is corrected by the power factor correction circuit 3. After the output bus voltage is tuned by the half-bridge LCC resonant circuit 4, Supply power to the ultraviolet lamp 10; the ultraviolet lamp 10 is...

specific Embodiment approach 2

[0070] Specific implementation mode two: see figure 1 and figure 2 Describe this embodiment, a method for optimizing the driving power of an ultraviolet lamp, which is implemented based on an electronic ballast experimental platform for driving ultraviolet lamps described in the first specific embodiment,

[0071] The method comprises the steps of:

[0072] Step 1: When the single-chip microcomputer 5 receives the voltage at both ends of the ultraviolet lamp 10 collected by the voltage acquisition device 9, it is determined that the ultraviolet lamp 10 is working normally, and at the same time, the single-chip microcomputer 5 determines the input power to the ultraviolet lamp 10 by the current collected by the current acquisition device 8. Value;

[0073] Step 2: adjust the given power received by the ultraviolet lamp 10, so that the power received by the ultraviolet lamp 10 is gradually increased from 60W to 160W, and the increase step is N, where N=5;

[0074] Step 3: Re...

specific Embodiment approach 3

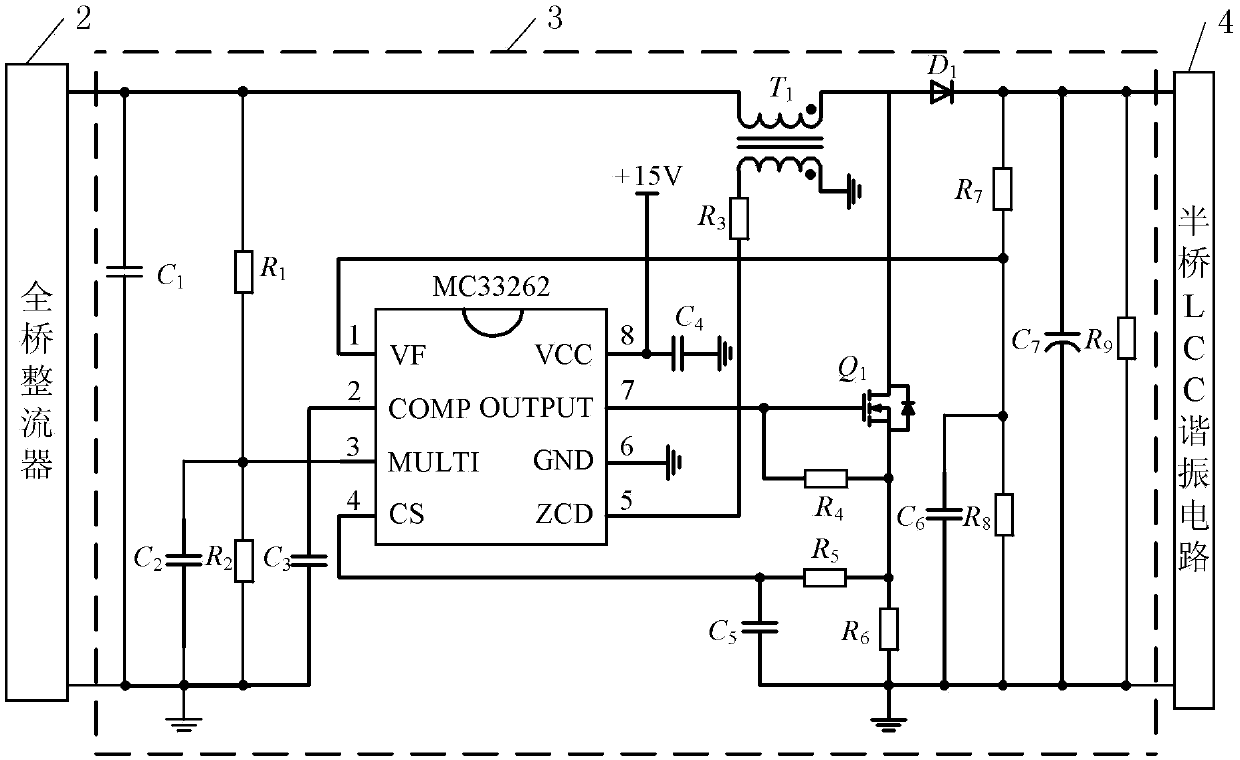

[0086] Specific implementation mode three: see Figure 1 to Figure 3 Describe this embodiment, the difference between this embodiment and the method for optimizing the driving power of an ultraviolet lamp described in the second embodiment is that the power factor correction circuit 3 includes a capacitor C 1 to C 7 , resistance R 1 to R 9 , Diode D 1 , Transformer T 1 , Power switch tube Q 1 And MC33262 chip;

[0087] Capacitance C 1 The two ends of are used as the voltage input terminals of the power factor correction circuit 3;

[0088] Resistance R 9 The two ends of are used as the voltage output terminals of the power factor correction circuit 3;

[0089] Capacitance C 1 One end of the resistor R 1 one end of the transformer T 1 The opposite ends of the primary coil are connected at the same time, the resistance R 1 The other end of the capacitor C 2 One end of the resistor R 2 One end of the chip is connected to pin 3 of the MC33262 chip at the same time; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com