Decoring Machine/Vibrating Machine With Improved Drive

A technology of vibrating machine and transmission device, applied in the direction of vibrating fluid, cleaning method and appliance, chemical instrument and method, etc., can solve the problems such as short service life of coring machine/vibrating machine, reduce quality and reduce manufacturing cost , The effect of shortening the drive line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] First of all, it should be pointed out that in the different described embodiments, the same components are provided with the same reference signs or the same component names, wherein the disclosures contained in the entire specification can be transferred to the same reference signs in a meaningful way. Or on the same part with the same component name. Position descriptions selected in the description, such as upper, lower, lateral, etc., also refer to the directly described and illustrated figures and are transferred by meaning to the new position when a position is changed. Furthermore, individual features or combinations of features in the different exemplary embodiments shown and described can themselves also be independent, inventive or solutions according to the invention.

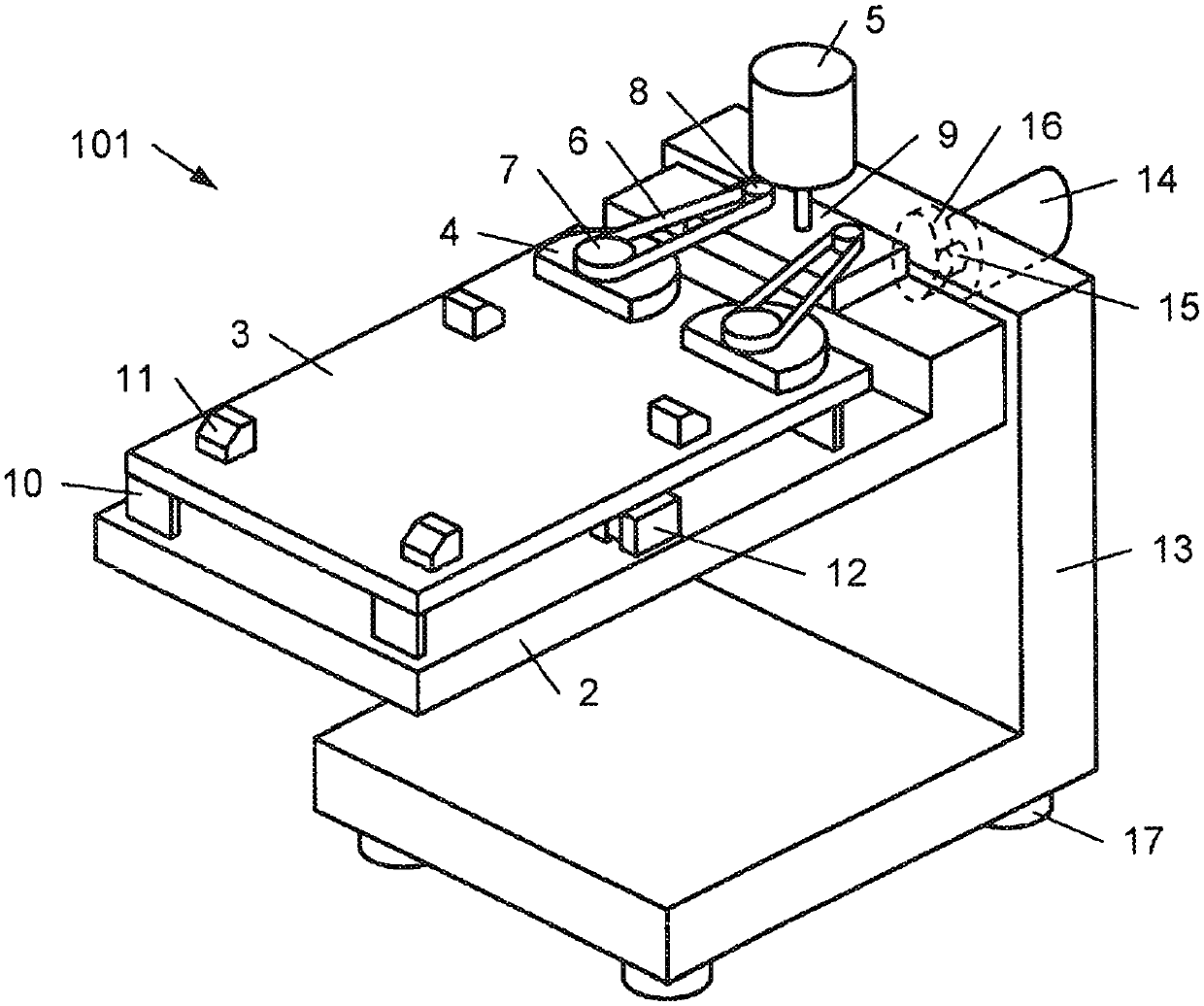

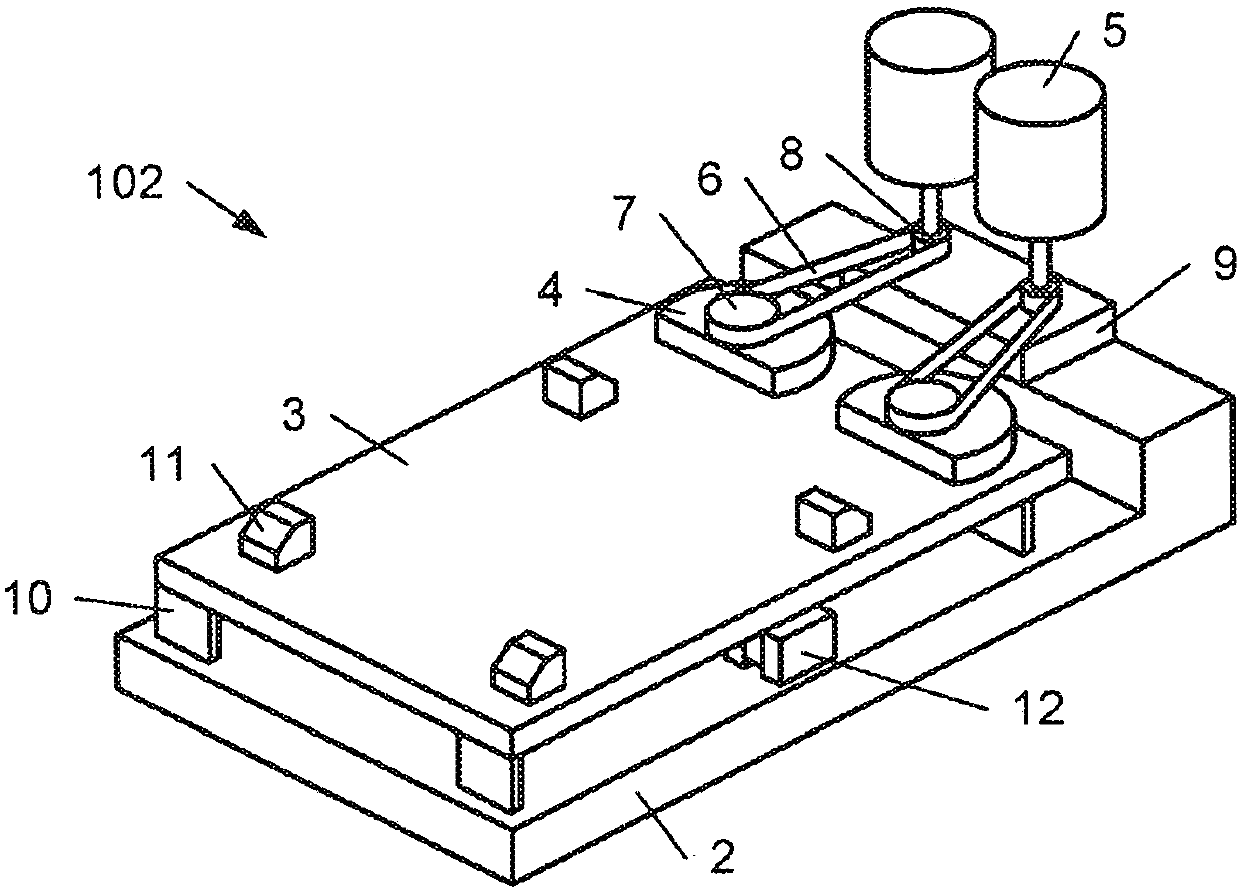

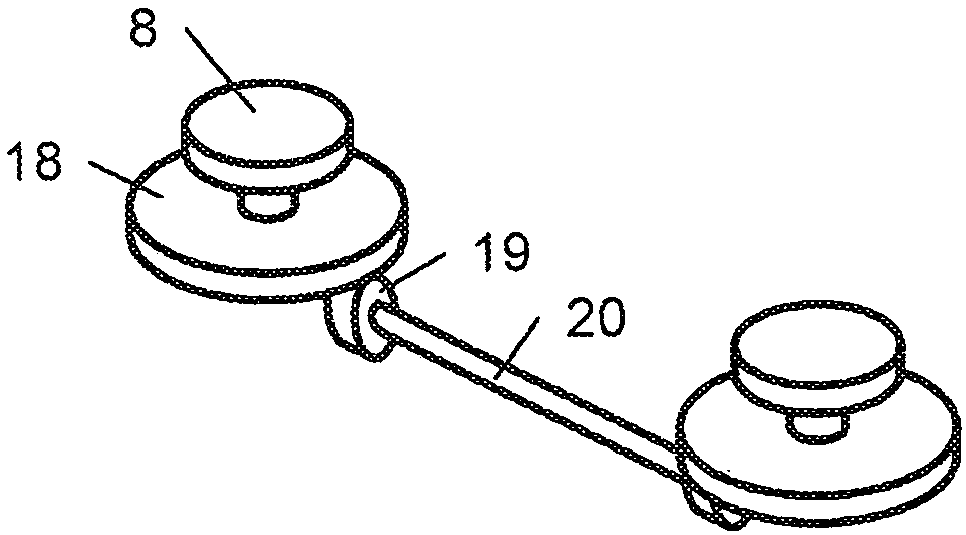

[0030] figure 1 A first example of a corer or vibrator 101 is shown in an oblique view. The corer / vibrator 101 comprises a first frame 2 , a table 3 movably supported relative to the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com