Plate polishing machine with dustproof function

A technology for polishing machines and plates, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., which can solve the problems of increasing the cost and disadvantages of processing enterprises, and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

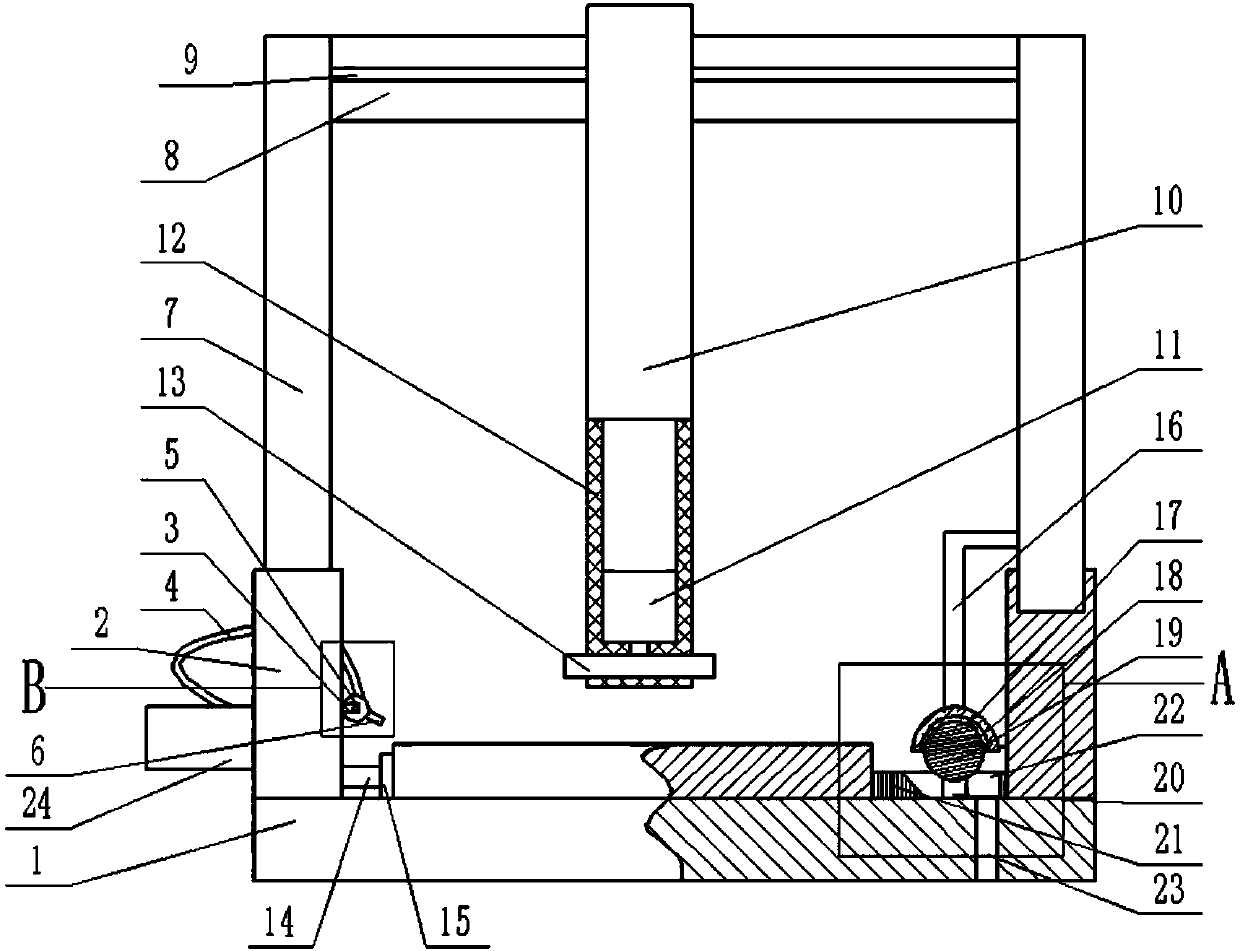

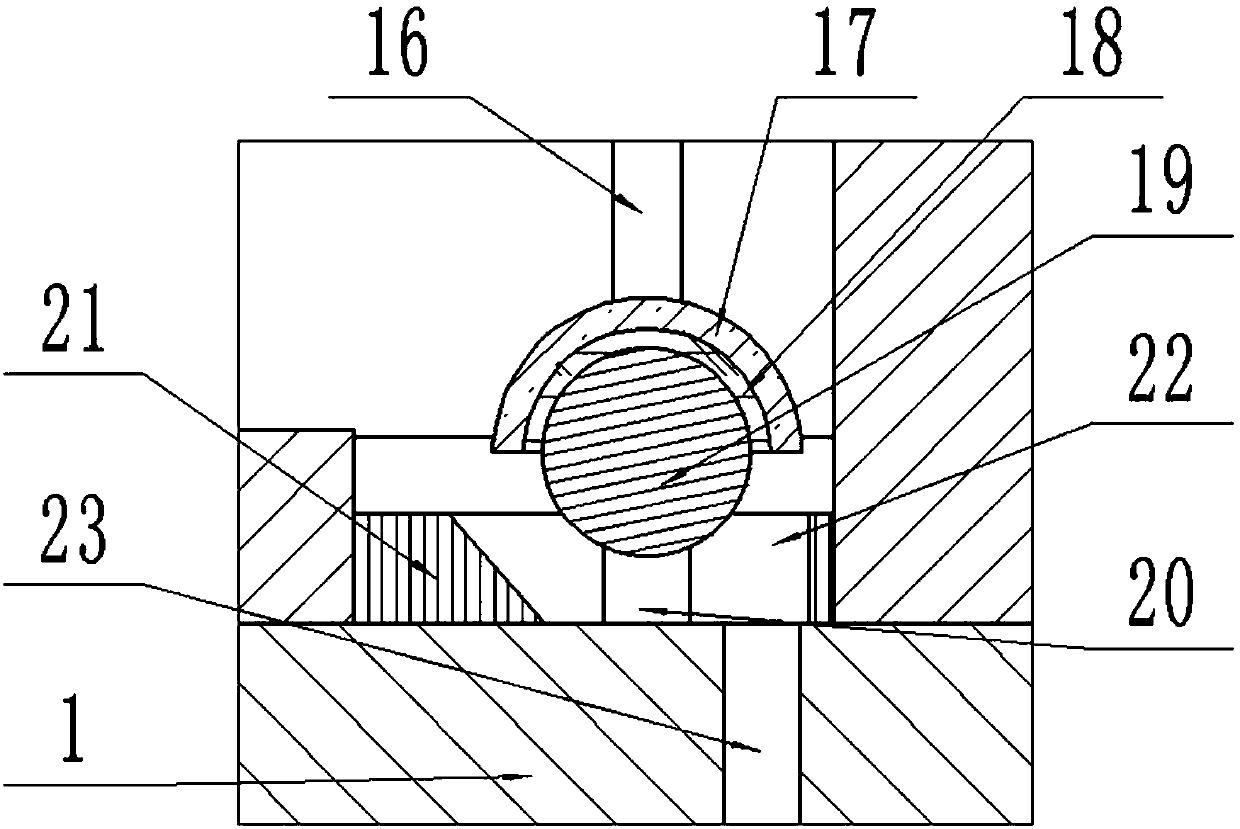

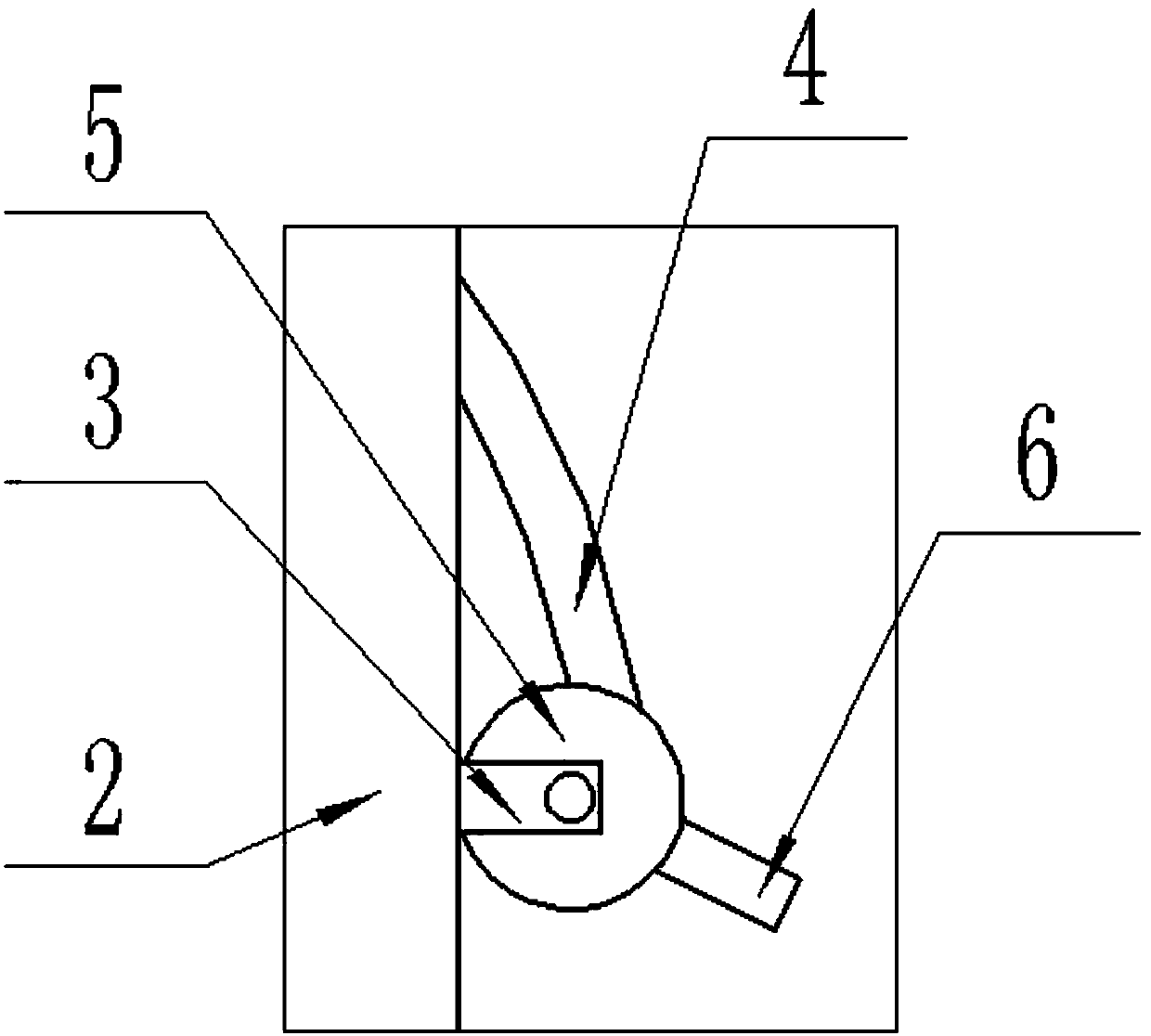

[0018] Such as Figure 1-3 As shown, a plate polishing machine with dust-proof function includes a platform 1, the left and right sides of the platform 1 are provided with longitudinal slide rails 2, and vertical slide rails 2 are provided with vertical rods 7 for sliding fit thereof, and the vertical rods 7 The upper end is connected by a horizontal connecting rod 8, the front of the connecting rod 8 is provided with a slider 9, and the telescopic rod faces the cylinder body of the electric telescopic cylinder 10 of the platform 1 to slide and cooperate with the slider 9, and the lower end of the telescopic rod of the electric telescopic cylinder 10 is provided with a The rotating shaft faces the motor 11 of the platform 1, the rotating shaft of the motor 11 is provided with a polishing wheel 13, and the cylinder rear side of the electric telescopic cylinder 10 is provided with a steel wire mesh 12 inclined to its rear, and the lower end of the steel wire mesh 12 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com