Extraction method of krill oil

An extraction method and krill oil technology, applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems of other nutritional components destruction, solvent residue, affecting the utilization of krill protein, etc., and achieve high nutritional value , No organic solvent residue, high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

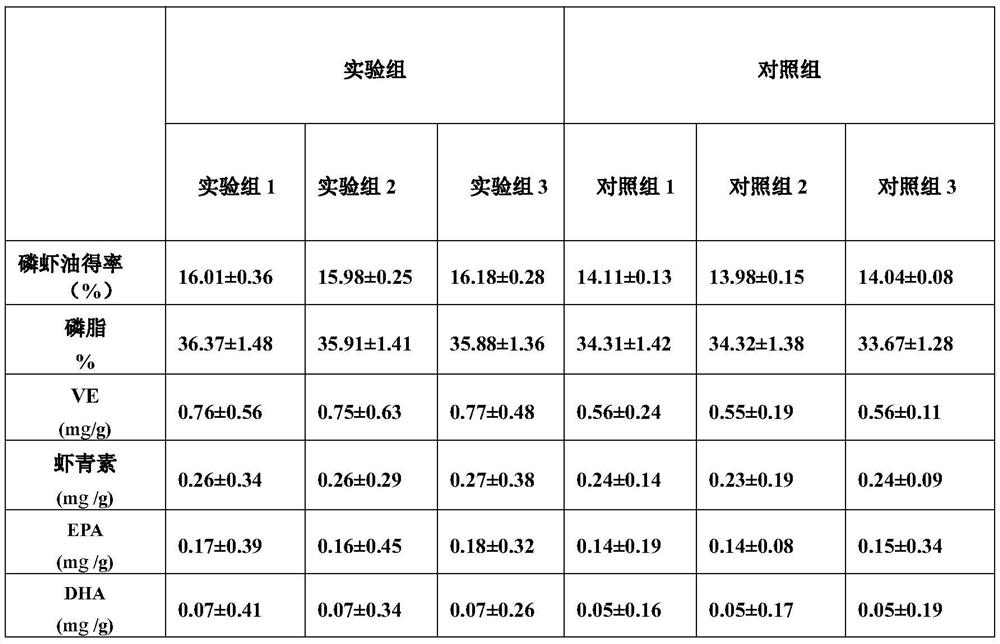

Embodiment 1

[0049] A method for extracting krill oil, comprising the following steps:

[0050] Step 1. Dry the body surface moisture within 3 hours after Antarctic krill is caught, and collect the blown liquid I; wherein, the step 1 also includes the following steps: a. Evenly laying Antarctic krill on the A multi-layer drying net distributed from top to bottom, and the multi-layer drying net is arranged in a relatively airtight drying device; b. From the bottom of the drying device, dry nitrogen gas is passed into it, and the temperature of the nitrogen gas is 50°C; c. Nitrogen is discharged from the outlet of the drying device after passing through the multi-layer drying net; d. The discharged nitrogen with water vapor is separated by water vapor to obtain liquid I;

[0051] Step 2. Freeze the Antarctic krill after drying the body surface, and then use microwave thawing treatment, and repeat the freezing and microwave thawing treatment twice; the internal temperature of the frozen Antarct...

Embodiment 2

[0063] A method for extracting krill oil, comprising the following steps:

[0064] Step 1. Dry the body surface moisture within 2.5 hours after the Antarctic krill is caught, and collect the blown liquid I; wherein, the step 1 also includes the following steps: a. Spread the Antarctic krill evenly on the A multi-layer drying net distributed from top to bottom, and the multi-layer drying net is arranged in a relatively airtight drying device; b, from the bottom of the drying device, dry nitrogen gas is passed into it, and the temperature of the nitrogen gas is 55 ° C; c. Nitrogen is discharged from the outlet of the drying device after passing through the multi-layer drying net; d. The discharged nitrogen with water vapor is separated by water vapor to obtain liquid I;

[0065] Step 2. Freeze the Antarctic krill after drying the body surface, and then use microwave thawing treatment, and repeat the freezing and microwave thawing treatment 3 times; the internal temperature of th...

Embodiment 3

[0077] A method for extracting krill oil, comprising the following steps:

[0078] Step 1. Dry the body surface moisture of Antarctic krill within 2 hours after fishing, and collect the blown liquid I; wherein, the step 1 also includes the following steps: a. Spread the Antarctic krill evenly on the A multi-layer drying net distributed from top to bottom, and the multi-layer drying net is arranged in a relatively airtight drying device; b. From the bottom of the drying device, dry nitrogen gas is passed into it, and the temperature of the nitrogen gas is 60°C; c. Nitrogen is discharged from the outlet of the drying device after passing through the multi-layer drying net; d. The discharged nitrogen with water vapor is separated by water vapor to obtain liquid I;

[0079] Step 2. Freeze the Antarctic krill after drying the body surface, and then use microwave thawing treatment, and repeat the freezing and microwave thawing treatment 3 times; the internal temperature of the froze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com